APEowner wrote:Bobzilla wrote: In reply to Chadeux: trust me, a TPI is a fantastic platform for that. idle to redline the power is always there. The downside... redline is ~4500-5k. The upside is that even at 1500 you'll still be making 300+ftlbs of torque.Yup. My TPI Vortec motor makes over 350 ftlbs from 1,500 to 4,500 and it's over 400 from 2,000 to 3,900. That's a bone stock L-31R crate motor with the Scoggins-Dicky lower, GM upper TPI and an AEM ECU. That would be an awesome street/autocross motor.

This actually sounds like a great truck motor, instead of LS swapping my 91 C1500, I could just get a set of Vortec heads, refresh my block and use these parts, tune with a Megasquirt or the AEM. Everything should bolt right up and be cheaper than the so called "junkyard" LS swap. I would love 400 ftlbs of torque!![]()

In reply to 06HHR:

I'm just sitting here thinking about a pretty much stock small block chevy that makes more torque than an early 6BT Cummins.

Bobzilla wrote: In reply to Indy-Guy: The LT1's were an evolutionary step. The main problem with them is the limited numbers built (92-96), the reverse cooling/special waterpump and the front mount distributor that sucked. Modern aluminum heads flow as well/better than the old LT1's and are much cheaper than trying to build one. But if you have one, and you want to use it they can make power.

I very strongly disagree about the optispark sucking. The optical pickup is bulletproof and insanely accurate. People complain about them because they require pulling the water pump to replace, but they often give 100k+ miles of flawless service. Try to get that from a traditional cap and rotor.

The other problem with them wasn't the optispark's fault at all. The weep hole for the water pump drips coolant on them and shortens their lives, but that was all but solved with later units being vented. I love my optisparks. Compact, 65kv of highly accurate spark, long life.

In reply to curtis73:

Flaws (to me) lead to suckiness. Putting the electronic device that ignites the engine directly below something that WILL seep water is the dumbest idea this side of the Mopar 2.7

Bobzilla wrote: In reply to curtis73: Flaws (to me) lead to suckiness. Putting the electronic device that ignites the engine directly below something that WILL seep water is the dumbest idea this side of the Mopar 2.7

Or (as many have done) is just use some jb weld to put a little piece of brake line in the weep hole and use a piece of hose to route drippage away from the opti.

My current LT1 had 140k on it with a dripping pump before it finally snapped a rotor. The truth behind optisparks is not anything like what the intarwebs thinks.

Its like when people complain about the KDP in Cummins and how they'll never own one despite the fact that its a $6 fix and isn't a problem until about 400k miles.

But we're in agreement on the mopar 2.7L ![]()

In reply to curtis73:

the biggest problem with the LT1 was how they stuffed them into the 4th gen. they were a mother to work on in those cars. Not quite as bad in the B-body, but getting to the rear plugs sucked.

In reply to Bobzilla:

That has nothing to do with the LT1, LS1 plugs in a 4th gen are just as bad. SBC plugs in my 3rd gen aren't much better.

Chadeux wrote: So in the thought process of trying to decide how to get the GTA rolling again. The "it's certainly a 350" I have seems like the right option if I wanted to spend no money and just wanted to slam it together and then ignore. The basket case L98 I have seems like the right answer if I want to tear it down and send it to a machine shop. So now I'm looking at other options. Like a 90s Vortec 350. I have questions. Question 1. What exactly has to be done to a Vortec head to make it work with a bigger cam that actually makes power? Everytime I google for that answer I find something different. Question the other. Does anyone know of a decent and reasonably priced EFI intake manifold that would bolt to those heads and fit under a flat 3rd gen Firebird hood? I'd use the stock truck manifold but I don't want spider injectors. My other dumb idea was a marine manifold that apparently uses normal injectors but I haven't actually tried to find one yet.

The Marine idea is a great one, but they aren't very easy to find. Find some marine salvage yards near water and you might get lucky, but expect to pay some moolah for it.

The suggestion I always come back to with a budget/easy SBC is to TBI it. I personally detest TBI for the most part, but I have work-arounds. First, many of the TBI issues have to do with the rest of the engine; loose guides and cheap valve seals cause oil burning, many of the blocks were not roller-cam-ready, etc. But if you keep those things in mind, you'll be fine.

TBI swirl-port heads were awful. They were the lowest-flowing SBC head Chevy ever cast including for a 283 in the 50s. They were going for low end torque and fuel efficiency. They failed miserably. Actual road MPGs were down compared to the electronic Qjet it replaced, the first batch only made 180 hp and sub-300 torque, and they fall flat on their faces at 4200 rpms. Some guys have ground away the swirl humps in the runners with modest success, but then you're still stuck with a tiny, inefficient port. Don't use swirl port heads. Period. I know you're making a low-end torquey motor, but the TBI heads are so small that they don't shine at anything except wheezing like a fat kid with asthma. (I was a fat kid with asthma so I can say that). Something like Vortec heads support greater bulk flow without huge ports which keeps the intake charge speed high. That's a win-win. You'll actually get more torque at the same low-rpms as the TBI heads, plus have more power above 3000. Throw in the fact that Vortecs have very efficient chambers and you can go about one full point higher in compression on cheap fuel furthering the benefits. Count on 8.7:1 with old-school heads, but 9.6:1 is easy-breezy with Vortecs.

Vortec heads flow very nicely. They flow more than any other production Chevy head on the intake side, and any shortcomings on the exhaust side can be handled with about 10 more degrees duration. They do like to crack between the exhaust valve and spark plug hole, so I suggest getting some aftermarket Vortecs from Summit which are not that expensive, they're brand new, cast thicker, and already allow more lift than stockers. Until you add up machining costs and/or aftermarket retainers for stock Vortec heads, you're darn close to just buying the Summit heads and bolting them on. IIRC, they are also drilled to accept either intake type; port mismatch notwithstanding.

For the TBI, don't use the 350 TBI unit. Its a horrid thing. They advertised flow at about 500 cfm, but until you get the nozzles on it and wet flow it, its more like 390. Get a 454 TBI. It actually flows a decent amount. The nozzles are still junk (they squirt liquid fuel at 27 psi unlike injectors that atomize fuel with 40-60 psi) because they are designed for volume. 2 nozzles are made to flow the same fuel as 8 injectors. Having said that, they are reliable and they physically work.

But as far as parts-bin surfing for the best of all, it won't happen easily. If I were personally doing it, I would spend the money on aftermarket replacement Vortec heads to avoid cracking issues, then put a Marine intake on it and hack a factory truck computer. (marine ECUs don't have enough control since they don't really rely on vacuum for anything, don't have as much varying climate needs, and don't have as many ways of changing the maps for differing conditions). Then I would get into and realize how much headache and money its going to be and remember that I'm pretty good at building Qjets.

BTW... Marine is also a good source for Vortec carb intakes. When marine engines went to Vortec longblocks, they didn't necessarily go EFI. Most had Qjets. You could order a ZZ4 intake for $$$, or get an Edelbrock carb-vortec intake for $$$$$$, or just find a junkyard Mercruiser vortec carb intake for scrap money. The Marine carb-vortec intakes are licensed copies of the ZZ4, so they would work beautifully. I have built a few handfuls of carbed vortec engines using marine carb intakes and they work great. Its one of the cheapest ways to get Vortec performance with a carb and not pay $400 for the intake itself.

Chadeux wrote: In reply to 06HHR: I'm just sitting here thinking about a pretty much stock small block chevy that makes more torque than an early 6BT Cummins.

It is pretty amazing when you think about it. Makes you wonder why Chevy didn't do it themselves. I had a 97 Firebird Formula with the LT-1 - 4L60E combo, even with the highway gears in the rear end (I think I had a 2.73, it would cruise at 70 turning just over 2000 RPM) that thing was really quick off the line, just tons of torque in any gear. Even though the LS F-bodies were on another level, I really miss that car. ![]()

06HHR wrote:APEowner wrote:This actually sounds like a great truck motor, instead of LS swapping my 91 C1500, I could just get a set of Vortec heads, refresh my block and use these parts, tune with a Megasquirt or the AEM. Everything should bolt right up and be cheaper than the so called "junkyard" LS swap. I would love 400 ftlbs of torque!Bobzilla wrote: In reply to Chadeux: trust me, a TPI is a fantastic platform for that. idle to redline the power is always there. The downside... redline is ~4500-5k. The upside is that even at 1500 you'll still be making 300+ftlbs of torque.Yup. My TPI Vortec motor makes over 350 ftlbs from 1,500 to 4,500 and it's over 400 from 2,000 to 3,900. That's a bone stock L-31R crate motor with the Scoggins-Dicky lower, GM upper TPI and an AEM ECU. That would be an awesome street/autocross motor.

The L-31R is actually a truck crate motor. You can get the whole long block with a warranty for about $2k.

Can anyone think of a good reason not to just get a set of vortec heads and put them on the previously mentioned "certainly a 350"? It's an old 2 piece rear main flat tappet engine, but I already have it and the parts I'd need to make it work in the GTA.

Chadeux wrote: Can anyone think of a good reason not to just get a set of vortec heads and put them on the previously mentioned "certainly a 350"? It's an old 2 piece rear main flat tappet engine, but I already have it and the parts I'd need to make it work in the GTA.

No problem at all. See my earlier thoughts on which vortec heads to get. I wouldn't buy used vortecs unless they come with a receipt for a passing magnaflux test. By the way: the only "real" factory vortec heads have casting numbers ending in either 062 or 906. They are interchangeable. Feel free to mix n match

For $350 each, just get these instead.

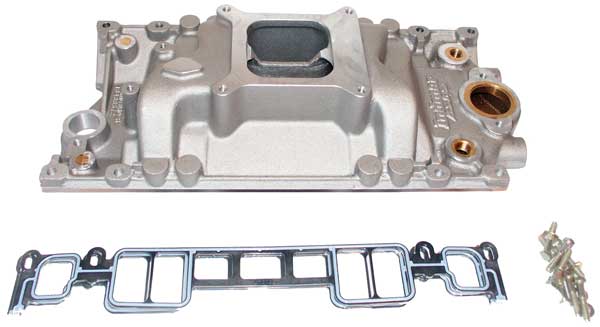

For the intake, this is basically what you're looking for. New it would cost you $400, but I've had pretty good luck at marinas finding them for $20-50 as take-offs. Many will be iron, but lots are aluminum too. Aluminum ones are easy to spot because the thermostat flange has a bronze lip. The marine aluminum intakes almost always have bronze-lined water passages for corrosion resistance.

In reply to Chadeux: It's done all the time, the Vortec heads are considered the best budget head you can buy for a SBC. It's exactly what Freiburger and co. did in the video linked back on the first page of the thread. The crate motor they started with is a stock reman pre-Vortec 350, basically what is sitting in my old truck, with a carburetor in place of the TBI. EDIT ^what he said...

NOPE.... just make sure the bottom end is solid. I made that mistake with dad's 97 Tahoe. Had a leaky headgasket. Pulled the heads and found a small crack. fixed it, did a valve job and seals and 7 miles later the crank ate 3 bearings.

Another problem many don't realize with the Marine EFI intake is that the throttle body is on top, and until you get an air cleaner or an elbow on it for ducting intake air, its no shorter than a carb setup.

In reply to curtis73:

There are cheap Vortec pattern 4 barrel intakes out there now. Summit has 8 for under $200.

Then a gen 1 SBC is probably not the motor you're looking for unless you're willing to spend the money on one of the 4 barrel throttle body injection units now on the market (FiTech, etc.). The problem is aside from some boats and the TPI system in corvettes and select F bodies they never got proper efi and no good stock parts means no good cheap junkyard parts.

Right, but you need a $400 lower manifold (or lots of welding and grinding on the stock one to raise the ports, maybe) to put TPI on Vortec heads.

You'll need to log in to post.