I was given an old set of electronic corner scales recently. The only markings on the display are "Gtech" and "Electronic Scales by Gravitational Technology." A quick google search yielded no results. I'm assuming the company is long gone, so support for these seem nonexistent. Unfortunately the display quit powering up altogether, I'm not sure if it shorted out or what happened. I'm wanting to reuse the pads that have the load cells in them but I am not having any luck finding ratings or specs on this setup. Is there anyway to repurpose the pads, or am I stuck with these free paperweights?

If you want help troubleshooting the existing display, maybe open up the box and post some pix of what's inside (other people here are good at electronics... not me).

Also take a look at this thread about DIYing a system using off-the-shelf scales: https://grassrootsmotorsports.com/forum/grm/diy-arduino-corner-weights/186240/page1/

The circuitry is almost definitely through-hole, which is very repairable. Open it up and look for crispy bits and broken solder joints.

G-tech made early windshield mounted accelerometers in the mid-90s. I think I have one :)

In reply to Keith Tanner :

I'm about to by a china special DIY kit for a platform scale. Made for cattle. So this thread caught my interest.

Question: what does "through hole circuitry" mean?

Thanks.

In reply to 03Panther :

A couple pix comparing the two common methods for attaching electronic components to a circuit board. Through-hole is easier to repair b/c you can do it with just a soldering iron, the components are bigger, and the legs make it easier to position the components before soldering. Surface-mount components can be effing tiny, it is much more difficult to place them on the PCB by hand, and you may need something other than a soldering iron to melt the solder.

In reply to Oapfu :

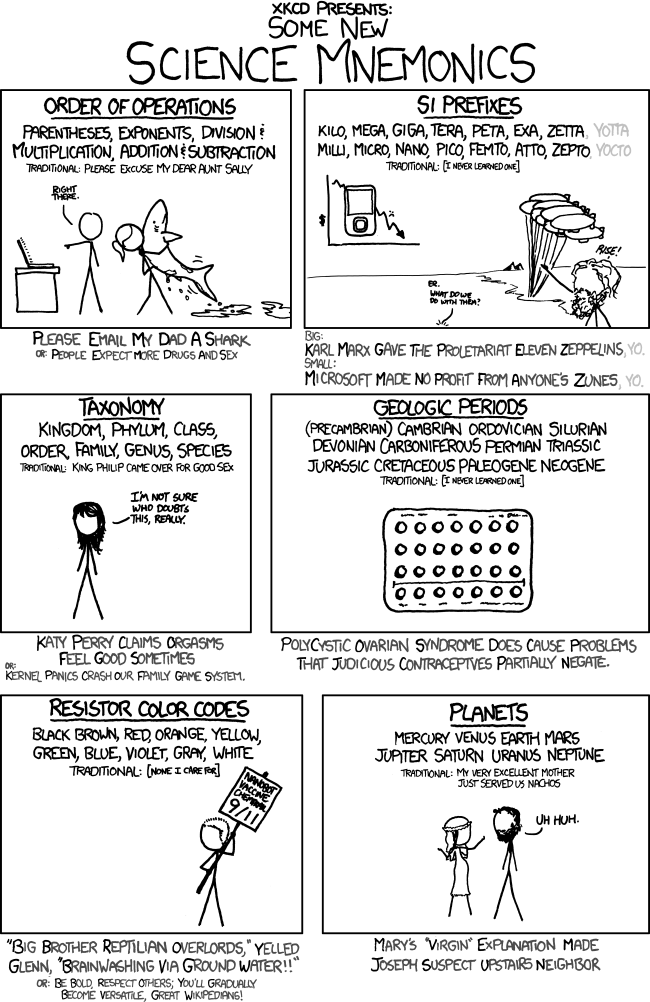

Exactly. Also, due to the size of the parts, it's usually easier to identify through-hole components. The resistor value is marked on each resistor in a special code, for example.

Thanks! Obvious, with the reminder. Not sue what I was thinking!

In reply to Keith Tanner :

I actually still remember the color codes, although I've only needed to know them 3-4 times since tech school, 45 years ago!

I hear they have a polite version, now. Bet I wouldn't still remember it!

In reply to Oapfu :

Great description! My dad (electrical theory industrial instructor) would have been proud.

Me, tending to be dense, without context, wasn't thinking circuit board. So many years of swapping cards!

As mentioned above this is old enough tech that it is going to be easy to figure out what the failure is and probably easy to repair. Open it up and you will probably find the failure pretty quickly.

If the display is really failed beyond repair (not likely) chances are good that the display is the only issue. The corner plates themselves probably have the load cell amplifiers in them. They would only need a regulated power supply (inside the display box) to get an electronically operational set of scales. The challenge will be to get or generate a calibration for the voltage outputs from each scale. They are all going to be the same rating (max weight - pounds) and slope (pounds/volt) within reason , so less than +/-2% for this level device.

In reply to Oapfu :

those would be harder to remember than just memorizing the colors!

They taught us the one about bad boys, and what violet does.

Even the tolerance bands of get, some, and now (n for no color band)

Also the joke about the fuse that has a smile on its face.

I've heard a clean one better than the above. Pretty good. But the bad boys is locked in my head, so I don't remember it.

Thanks everyone for the tips. I have the box apart and will start looking at all the joints soon. I believe there is corrosion? Not big into circuit boards but I can solder joints!

Here are pictures of the board if anyone is curious. I'll post updates and pictures as they happen.

Front

Back

Before you mess around with the board make sure the external power supply is working and that power is getting to the board.

Upon diag I found no output voltage from the regulator on the board. One is on order and I will go from there.

Were you ever successful in repairing it?

Looking at the board, it appears that the amplification happens at the board, and it is just the raw load cell signal coming from the scales.

Heres some info on the circuit for the load cells and the op-amps on the board: Intro to load cell circuits

If you aren't able to fix the one you have, there are option for strain gage meter that could be used to get things working.

Update:

Voltage regulator was replaced on the board and the scales are functional again. The board has calibration adjustments on it so I will be checking accuracy and calibrating them soon.

The voltage regulator has an input up to 35V, so I will be attaching a mount and using Dewalt batteries as a power supply for them.

Old regulator on the left and new regulator on the right. Cost to repair: $6 for a 20 pack of the regulators.

In reply to No Time :

Excellent article linked! I'll be reading his others for a while!

my last class in electronics was graduating from a two year tech school in 1981! I might be of the last generation taught the basics in tube theory. Since I switched over to persuing a mech. degree (didn't finish that, either!) I haven't had to think of tubes but a handful of times since. We were just starting to dip our toes into the digital "0" and "1" chips, when the two years were up.

Now, as an I&C tech, we mostly just change out modules... or even complete instruments, if they won't cal. correctly.

But my interest is still there.

Thanks, again.