Very relevant to my interests. Did you have to do any clearancing to make room for the 17x9 wheels? It's worth mentioning that those are +42 offset and stock offset is +48.

Also I think you meant that only rebound damping is adjustable on the ISCs?

Story by Wayne Presley

In our last installment, we introduced our rebuilt-title 2015 Scion FR-S, which we won at a Copart auction. After a few minor fixes, we had a nearly perfect FR-S that we proceeded to daily drive for the better part of two years. Now though, with visions of humiliating Caymans at track days dancing in our heads, it was time to start upgrading. We’ll be honest: We didn’t exactly reinvent the wheel here. Instead, we opted for a proven formula: A coil-over kit with stiffer shocks and springs, upgraded urethane suspension bushings and sway bars, wider, stickier tires on appropriately-sized wheels, and a few odds and ends to achieve a performance alignment. Call us boring, but as we said in our last update, this car isn’t about wild ideas or unattainable fab work: it’s about simple, effective modifications that will have us Porsche hunting.

We chose a coil-over kit from ISC Suspension. At a street price of less than $1000, their N1 coil-over kit seems like a bargain. Why’d we choose coil-overs instead of just upgraded shocks and springs that aren’t adjustable? We don’t care much about stance–the reason many people choose budget coil-overs–but we do care about cornerweights, since we’re building a track day car. Coil-overs allow for easy adjustment of corner weights. The shock body is also threaded, and the overall length can be adjusted by screwing the end cap in or out—another great feature, since it means we can adjust ride height without changing shock travel. No, these aren’t the fanciest coil-overs we’ve ever installed (only damping is adjustable, for example), but they seem to be well-made and the price was right. We couldn’t be happier. Oh, and while we were filling our ISC shopping cart, we ordered front control arm tie bars and rear adjustable control arms, too. These will help us get our alignment in check after lowering the car.

Next up: Suspension bushings. We’re not big fans of the compliant rubber bushings that come stock, and since we’re aiming for track days, not for a specific racing class, there are no rules to limit what we can change. SuperPro—a company originally from Australia that manufactures a wide variety of bushings, arms, sway bars and differential mounts for hundreds of applications—sent over a full suspension bushing kit, steering rack bushings, rear toe links and sway bars for our FR-S. Their bushings have a unique feature: it looks just like knurling inside the urethane bushing where the pivot pin is inserted. These thin grooves retain the supplied grease when you press the pins into the bushing, instead of the pin just pushing it out the back side. Much better than having to constantly regrease, especially on a car that will see lots of street miles.

We’ll be blunt here: Installing bushings is a royal pain in the rear, but they’re one of the best things you can do to a track car. The FR-S has a multi-link rear suspension with eight bushings that needed to be changed, while the front suspension has four. Removing the OEM bushings took every trick we knew to get them out: The front control and trailing arms required a propane torch to melt them out of their shells. Naturally, the bushing almost always catches fire right before it falls out of the arm. After extinguishing the molten rubber, we remove the outer shell of the bushing that is still in the arm, using a Sawzall to cut through it and tap it out with a hammer. We made sure we were outside in a well-ventilated area when using the torch and kept an extinguisher handy. The rear upper arm took an air hammer to take out the rear bushing, while we used a hydraulic press on the front. For the bushing in the rear spindle, we used a 1/4” drill bit to loosen the rubber all the way around the center steel. Then, using a piece of 5/16” all thread, two nuts, and a large socket, we pulled the center out. This allowed us to get the Sawzall in and cut the rest of the shell out. We used the same method to pull the bushings out of the steering rack, since removing the rack from the car would have been a huge pain. Once we were done cussing and giving a blood sacrifice removing the stock bushings, putting in the SuperPro bushings was a snap. Each SuperPro bushing has a center pivot sleeve and a pair of urethane bushings. Press the bushings in with your fingers, grease the inner knurled area and outer faces, and push in the center sleeve. Reinstall the suspension parts, put in the adjustable SuperPro sway bars, and set the ride height to get car ready for an alignment. Nice and easy. Our hands looked like we’d just graduated at the bottom of bomb squad class, but at least our car had shiny urethane bushings and stiffer sway bars.

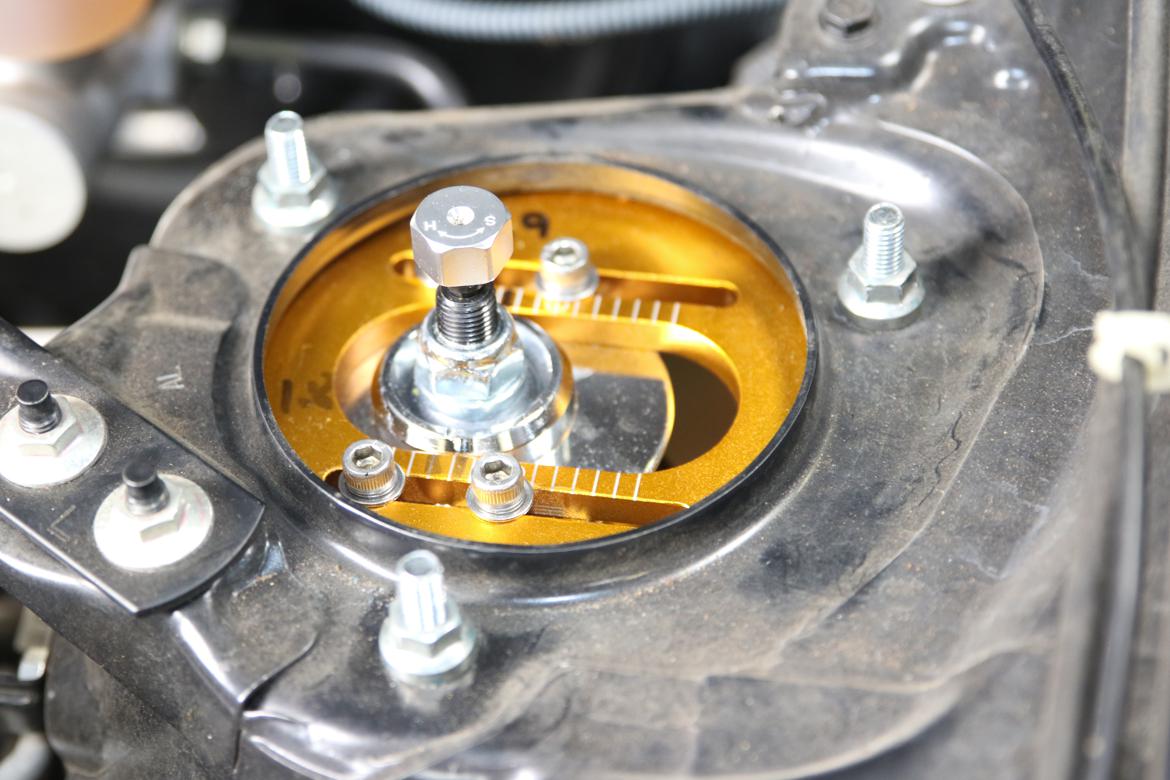

It was time to align our FR-S, so we turned to our trusty Paco Motorsports hub stands. These let us align the car without the wheels in the way, and feature roller feet that serve as turn plates. Pictured is their earliest version that we modified to measure thrust angle (their current offerings come with this feature). We set the plates and hub stands on the scale pads to get a 50% cross weight before setting the alignment. The hub stands make the alignment a breeze with all the adjustment points in clear view. The front lower arm bushing is offset to get a bit more caster, which will give us more stability and weight transfer. The ISC front coilovers have camber plates for easy adjustment, and the rear ISC lateral link and SuperPro toe links both have turnbuckles for precise setting of the alignment specs. We dialed in a slightly aggressive street alignment to keep our car comfortable ont the street but still competent on track. With the ease of adjustment, we’ll add some negative camber in the paddock before we go out on track.

We’d already installed a nicer wheel and tire package, but it was really just for looks. In order to lower our lap times, we turned to Mach V Motorsports. Our order? A set of their 17x9 Awesome wheels finished in gunmetal, each weighing a paltry 17.8 pounds. Sure, we cared about looks (We think the wheels really complement the charcoal color of the car), but the real reason we chose them was speed: We added 30mm of tire width, bumping from the previous 215/45 R17 size to 245/40 R17 all around. We didn’t want to exclude ourselves from street-tire autocross classes, so we chose a 200-treadwear tire, too: The Toyo Proxes R1R, which has plenty of grip without being unpredictable at the limit of traction.

So, were the upgrades worth it? We won’t have scientific data until we hit the track to (hopefully) beat up on some P-cars, but the butt dyno results are good. Stock, our FR-S was a good handling car. Now, though, our FR-S feels completely transformed. The turn in is razor-sharp with little body roll, yet we didn’t experience any twitchiness running down the highway. The ISC coilovers are firm without being harsh on the street, though we’ve got the damping dialed all the way down. The Toyos have slightly more road noise than the BFGs previously on the car, but are well worth it given the increased grip and confidence they inspire. In summary, not only does our FR-S now look, handle, and grip better, but we’ve sacrificed nothing when it comes to daily driving. With the suspension, wheels, and tires sorted, it’s time for the fun part: Adding the turbo. We’ll cover that in the next installment.

Very relevant to my interests. Did you have to do any clearancing to make room for the 17x9 wheels? It's worth mentioning that those are +42 offset and stock offset is +48.

Also I think you meant that only rebound damping is adjustable on the ISCs?

GameboyRMH said:Very relevant to my interests. Did you have to do any clearancing to make room for the 17x9 wheels? It's worth mentioning that those are +42 offset and stock offset is +48.

Also I think you meant that only rebound damping is adjustable on the ISCs?

BRZ/FRZ will fit up to a 265/35/18 without a roll with the right offset.

Enkei specifically built an RPF1 that was 18x9.5 +38 to run a 255/35/18 tire. Which is what I ran on mine with Star Specs. But to run 9"+ wide you do need to be on coilovers for the inner clearance up front.

I'm curious why you guys didn't opt for the SPL arms over the ISCs.

More adjustability and lets you set your ride height lower using the shock mounting hole so you maintain rear travel.

What's the reasoning for turbo vs supercharger on this specific car? There are several supercharger options. They should provide more linear torque and more reliability on the track. Is there a reason to chose a turbo over that?

I ask out of personal interest. I just bought a 2015 FR-S as track day car.

^General advantages of a turbo are greater efficiency and greater tunability (vs. a supercharger where all you can do is change pulleys).

In reply to z31maniac :

Was your RPF1 setup square?

I wonder how long the budget coilovers will last on the street.

GameboyRMH said:^General advantages of a turbo are greater efficiency and greater tunability (vs. a supercharger where all you can do is change pulleys).

An advantage of the roots/screw supercharger is packaging. There isn't a whole lot of room under the hood.

In reply to Appleseed :

Yep, square. There are tons of options for that fitment. ET35 works as well.

No idea on the budget coilovers, I don't mess with that stuff.

As for room, there is plenty. Look at the routing of the PTuning turbo kit.

Although if I was going to turbo a Twin, it would be Full Race or JDL.

For GRM staff: I'm getting ready to sell my '13 FR-S (will be very sad to see it go, but due to financial choices I've made selling the FR-S is what I have decided to do to get out of debt) and have a CAE Ultra shifter I would like to donate to the project FR-S. Will need a little work invested to make it useable again, but it is absolutely a beautifully shifting unit if properly fit/toleranced that deserves to be used by performance/track minded owners.

I didn't properly check clearances when originally installing it and it ended up actually being fused to the pin on the linkage rod shearing off the pin on the shift linkage rod after about 6 months of daily driver useage. The sheared-off pin is stuck in the base of the shifter. I had planned to properly fix it one day by removing the pin piece, welding in a custom slightly smaller OD pin on the factory linkage rod, and slightly enlarging the hole in shifter for a bushing for the pin for proper tolerances. Anyways, want you to have it for this project car if it is something you would be interested in. Absolutely incredible shifter unit that made going back to stock shift mechanism a HUGE downgrade.

Only thing with the CAE Ultra shifter (and the IRP shifter) is you REALLY need to have stiffer engine and transmission mounts for using this unit. The good news is ride quality actually becomes better with stiffer motor mounts than the factory mounts... and the Perrin mounts make any engine/transmission removal work much quicker/easier. Here's a DIY Guide thread I made for it on the FT86 Club forum if you want to research the CAE Ultra shifter:

https://www.ft86club.com/forums/showthread.php?t=95288

Feel free to contact me if interested.

P.S. And another thing to add that is really good to do is replacing factory steering rack bushings with solid aluminum or delrin two-piece units - I know ya'll have made your own delrin bushings before. Absolutely worth it on the FR-S...stock steering rack bushings are horrible, even brand new...super soft rubber with minimal support and excessive slop between bolt and sleeve (bad tolerance).

Displaying 1-10 of 11 commentsView all comments on the GRM forums

You'll need to log in to post.