In reply to RossD :

It's not open to the oil. It's just a tunnel through the sump for the front axle on the 4x4 Trailblazers.

In reply to RossD :

It's not open to the oil. It's just a tunnel through the sump for the front axle on the 4x4 Trailblazers.

Toyman01 said:In reply to RossD :

It's not open to the oil. It's just a tunnel through the sump for the front axle on the 4x4 Trailblazers.

Correct, 2wd use the same pan except without the diff bolted to it.

edizzle89 said:MrJoshua said:TheV8Kid said:yupididit said:The Toyota 1fzfe would-be be a cool alternative to the gm 4200. Its basically a big 4.5 liter 2jz for trucks lol. They make huge power when boosted.

To be honest, I did not even know that engine existed until a couple of minutes ago. How much horsepower can they take with stock internals?

If the guys from the middle east are to be trusted-All of it.

Yea it's the late FJ80 engine and those guys in the middle east pump north of 1000 hp out of them like it's going out of style.

I also am stoked to see the 4200 getting some love, i think they have really great potential that alot of people dont realize, it's just their large size that is their weakness but in a full size truck it's probably less of an issue. There is a mk3 supra with a boosted 4200 that i saw on the interwebs a while back so with some work they can be made to fit on smaller-ish cars.

Yeah, I'm a big fan of that Supra. It is pretty rare when you one swapped into a car. I actually saw this car in person at the Carlisle Imports show. Very cool car.

In reply to maschinenbau and RossD :

My plans are to cut the tube out, and weld the holes shut for additional oil volume.

Patrick said:tuna55 said:I want to see how to dress the thing out of its ugliness (the 4200, not the truck) but I love that engine.

Close the hood

I plan to make my own custom intake and exhaust manifold. I don't think it is an ugly engine at all. I think it is very attractive. To each his own.

Glad everyone is enjoying it so far. This is going to be a lower priority project. Still have to get the Nova done!

I have a lot of projects! I'll keep you updated as things happen.

The latest Project Binky episode really has me inspired to make the heat work and try to make a custom AC setup.

One hurdle of the Atlas engine is the bell housing bolt pattern. It is completely unique from any other engine. For a lot of people this means you are stuck with a 4l60e. We've all heard horror stories about the 4l60e, and to build one to handle the power numbers I am aiming for would be expensive (>$1000).

I can't imagine why GM chose to do this, but they left us all an Easter egg. The dowel pins which align the transmission are in the same spot in relation to the crankshaft center point as they are on a small block Chevy. Therefore making an adapter plate is very doable.

Some people might take a small block bell housing and a transfer punch, and layout the pattern on a piece of metal. Then take an Atlas bellhousing and transfer punch it on that same piece of metal. Drill holes and call it a day. This would be fine. The dowels would align the transmission, and who cares if the bolts are a micron to one side or the other.

Us however, we have a milling machine, and CAD!

If you choose to go this direction, the next issue is, finding the pattern. I could not find it anywhere. I probably should have asked the forum, because one of you is probably going to reply telling me where it is, but such is life.

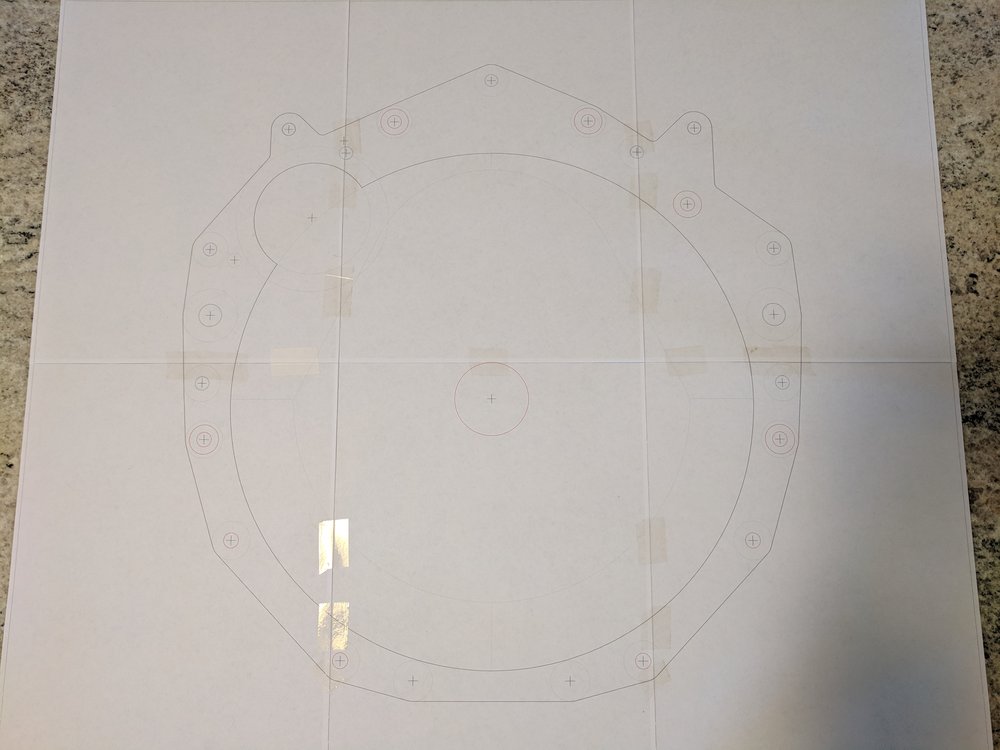

My brother who is a wizard with CAD went about laying it out. A bunch of measurements later and...

Tada!

It actually shares the same bellhousing as the 4 and 5 cylinder colorados/canyons which did have a manual option but from what i've read about them people say they aren't very strong, probably best to go with the adapter like you've started working on.

edizzle89 said:It actually shares the same bellhousing as the 4 and 5 cylinder colorados/canyons which did have a manual option but from what i've read about them people say they aren't very strong, probably best to go with the adapter like you've started working on.

But would that bellhousing be adaptable to some other transmission that was stronger? If so it may be a neater solution than having to machine an adapter plate (although if the V8kid is going with an automatic transmission it won't apply.)

Inline 6, turbo, my guess would have been a 6bt cummins.... That would be fun! Still looking forward to seeing the project, you guys build cool stuff.

AWSX1686 said:Inline 6, turbo, my guess would have been a 6bt cummins.... That would be fun! Still looking forward to seeing the project, you guys build cool stuff.

Thanks! This is a swap I have been wanting to do for years. Thanks for following along!

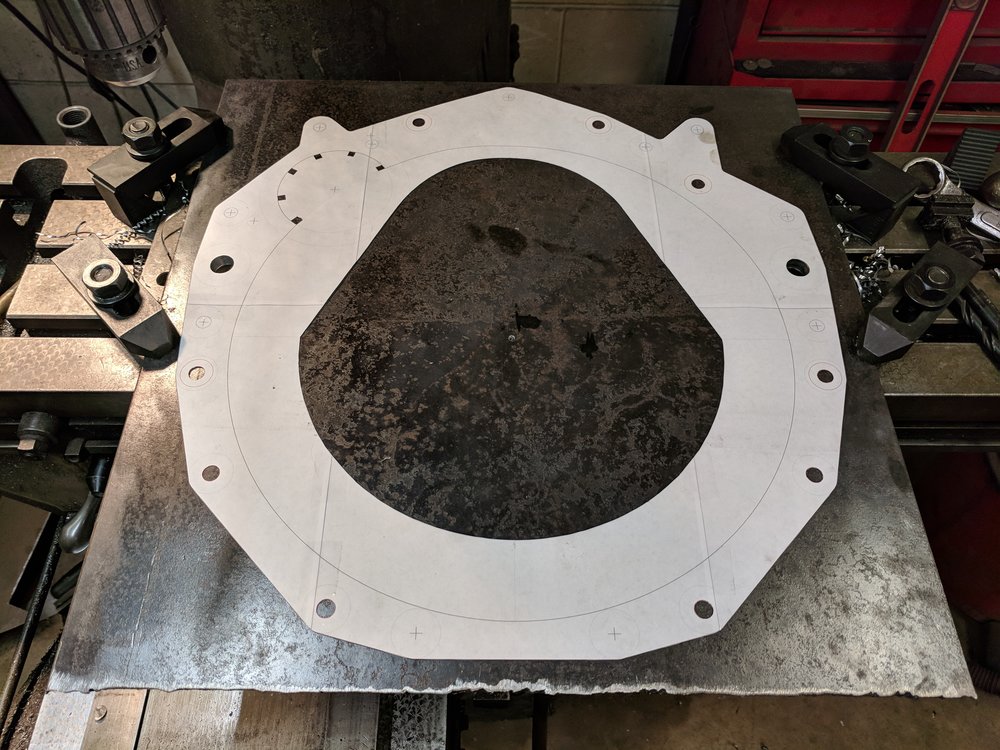

Adapter plate work continues.

We picked up a piece of 3/8 plate and threw it on the mill.

Once all the holes we drilled, we chucked it up on the rotary table.

20 hours of machining later...

In reply to TheV8Kid :

safety glasses and ear plugs FTW!

And from a production perspective, keeping the dowels in the same locations relative to crankshaft probably allowed them to reuse existing tooling / fixtures / dunnage (shipping apparatus) for one or more steps in the process.

In reply to TheV8Kid :

Corvair beat me to the ![]() for the ear and eye protection.

for the ear and eye protection.

One more thing, please roll up your shirt sleeves working around spinny things!

Sorry, just the shop teacher in me coming out.

The plate looks great by the way. Nice to see some folks still know how to do things 'The Old Way"!

AngryCorvair said:In reply to TheV8Kid :

safety glasses and ear plugs FTW!

And from a production perspective, keeping the dowels in the same locations relative to crankshaft probably allowed them to reuse existing tooling / fixtures / dunnage (shipping apparatus) for one or more steps in the process.

Thanks for looking out for me.

I never thought about that. Makes sense. I'm glad they kept them in the same spot. This would be way harder to do with out that.

In reply to SaltyDog :

I will have to try to remember to do that.

I am very thankful to have the tools to do it the "the old way". I can't wait to get the tools to do it the the new way someday as well. The rotary table is one of my favorite tools, but a CNC machine would be awesome to have.

TheV8Kid said:I am very thankful to have the tools to do it the "the old way". I can't wait to get the tools to do it the the new way someday as well. The rotary table is one of my favorite tools, but a CNC machine would be awesome to have.

From a retired machine shop teacher: But learning to do it the "old way" will give you a lot of experience about feeds, speeds, etc when it comes to programming the "new" way.

You'll need to log in to post.