NOTE: Scrap cost of lead is currently about $0.38 per pound.

IF you can get it at scrap value, I bet you are looking at almost $200 in lead. ![]()

NOTE: Scrap cost of lead is currently about $0.38 per pound.

IF you can get it at scrap value, I bet you are looking at almost $200 in lead. ![]()

Funny thing is, my car handles better with the ballast than without, as the front to rear balance is closer to 50/50. I would have to weight it again, but it was at least 52/48 if not 51/49 front to rear. Before the ballast it was tail happy when getting on the throttle, getting off the throttle or anytime it felt like. It is still a bit tail happy but much better than before. That is one good side to the over 310 engines, easier to put the ballast where needed.

There is a demented part of me that wants to put a 4.3 V6 in my car, to run it at a much lower weight (down around 2500 lbs). Trying to make a high horsepower 4.3 V6 gets expensive quickly, it makes the V8 stuff seem downright cheap.

Can you add boost to the 4.8? Seems like it would be the cheapest way to high horsepower and low weight. Unless cp rules say no.

Dusterbd13 wrote: Can you add boost to the 4.8? Seems like it would be the cheapest way to high horsepower and low weight. Unless cp rules say no.

No boost unless the car originally came with it.

I don't remember the maths off the top of my head, but forced induction is calculated into the weight and there isn't much advantage there. NA for me.

In Appendix A for CP there are no forced induction V8s allowed, only 4 and 6-cyl ones. So the 301 turbo would be a no go.

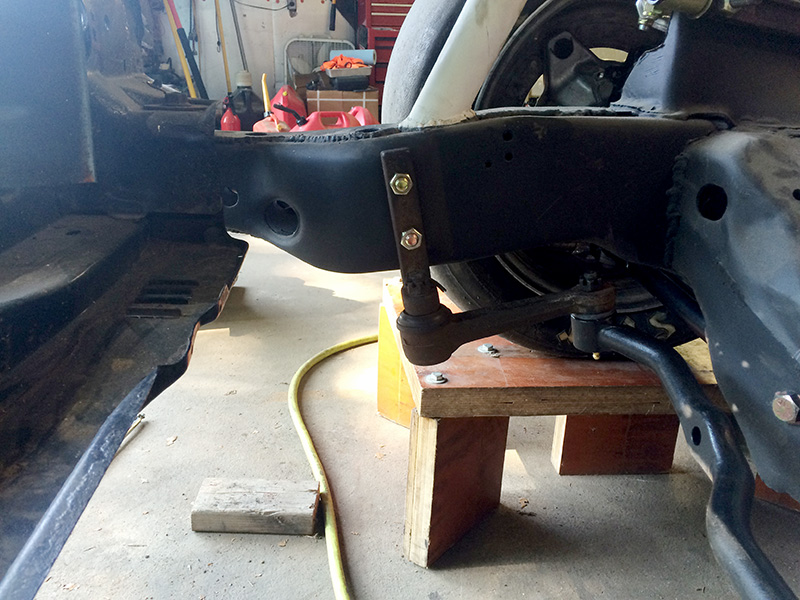

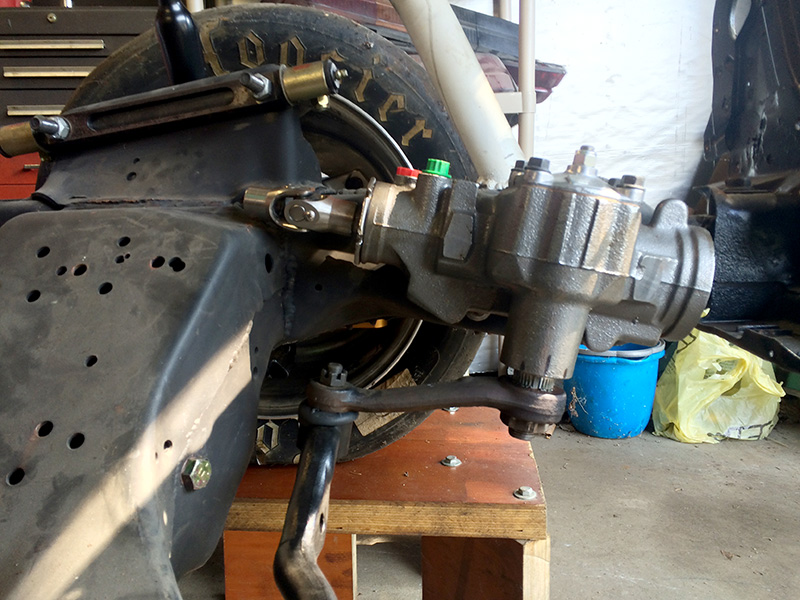

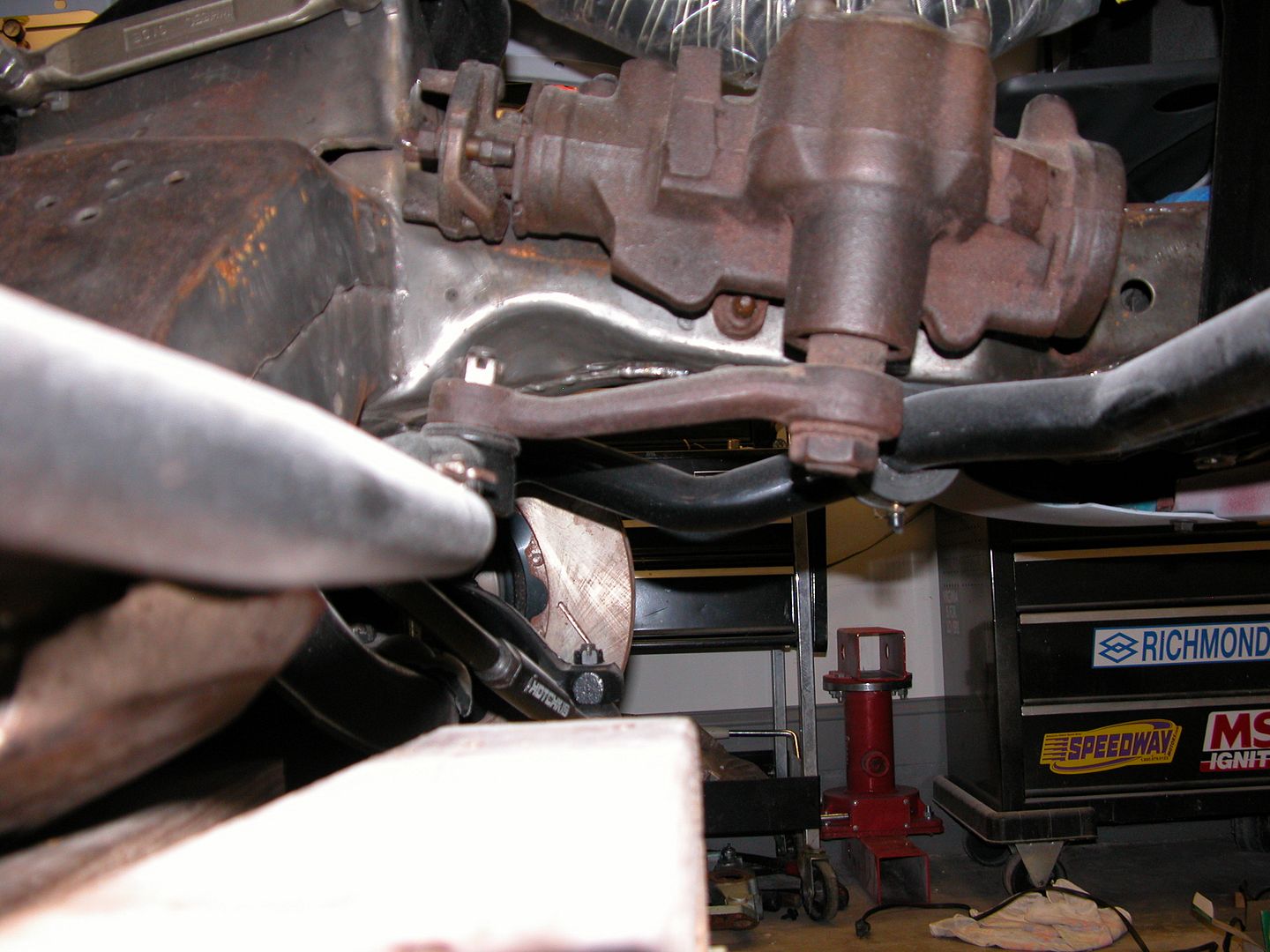

So I took the day off today to make some more progress on the steering, and ran into a bit of an issue.

My car started life as a V6 car, so I'm still using the V6 Pitman arm. I ordered a new centerlink (http://www.rockauto.com/catalog/moreinfo.php?pk=1284399&cc=1035313&jnid=485&jpid=2) and compared it to my old one when it arrived (exact match). I also ordered a new Idler arm (http://www.speedwaymotors.com/1970-81-Camaro-Firebird-Idler-Arm,4020.html).

(new idler)

(new idler)

When I started to put stuff together, I noticed that the replacement pitman arm placed the centerlink on the passenger side higher than stock. This created a slope in the centerlink. I then pulled the new idler arm off, and put the stock one back on. It was lower, but the points where the tie rods attach are still not level.

(stock idler)

(stock idler)

(centerlink)

(centerlink)

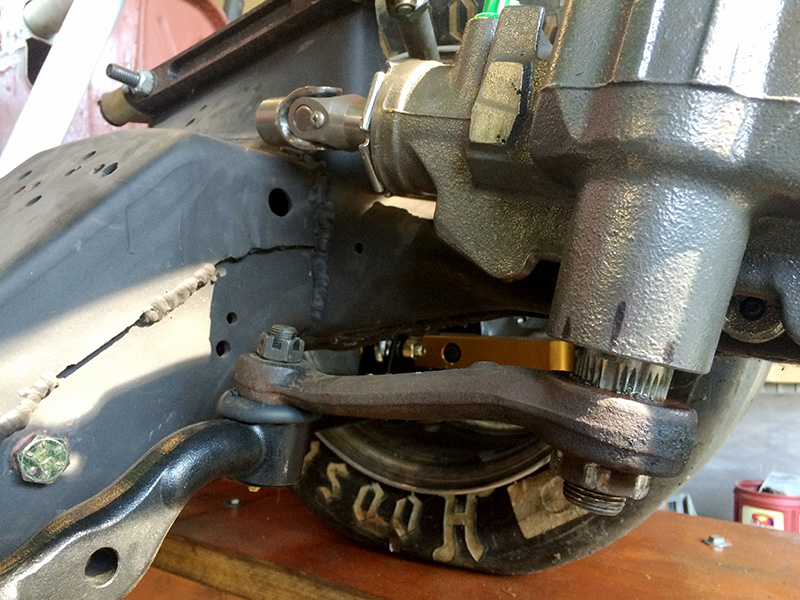

So now I'm starting to wonder if I've installed the stock Pitman arm correctly. I used the old nut and an air impact gun to run it on, and it is about as far as it will go. Is it upside down? Do I need a stronger gun? Some other problem?

(stock idler on AGR box - as far as it will go on)

(stock idler on AGR box - as far as it will go on)

So, that's the question part. If anyone has any ideas, please let me know.

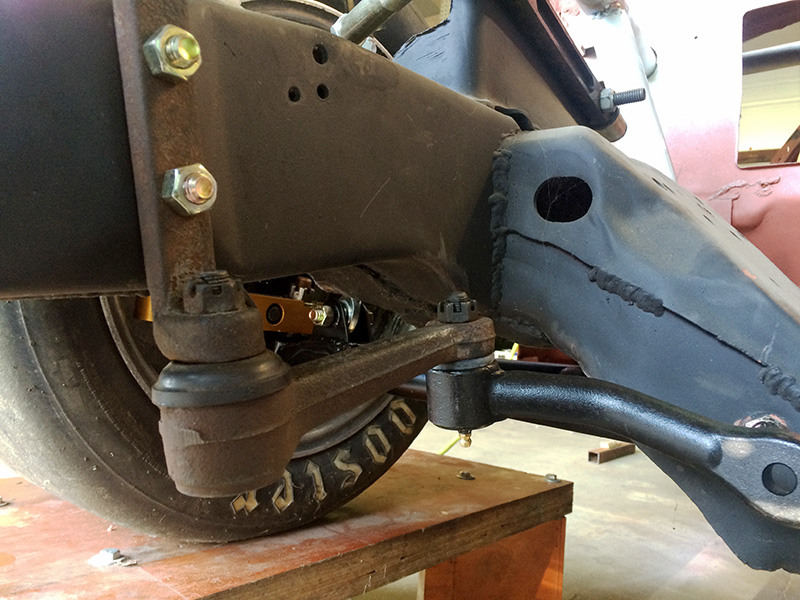

Once I was sufficiently frustrated with that, I went ahead and made my outer tie rods. These use a factory inner tie rod, and then a heim joint on the end that will hook up to the steering arm once I determine ackermann.

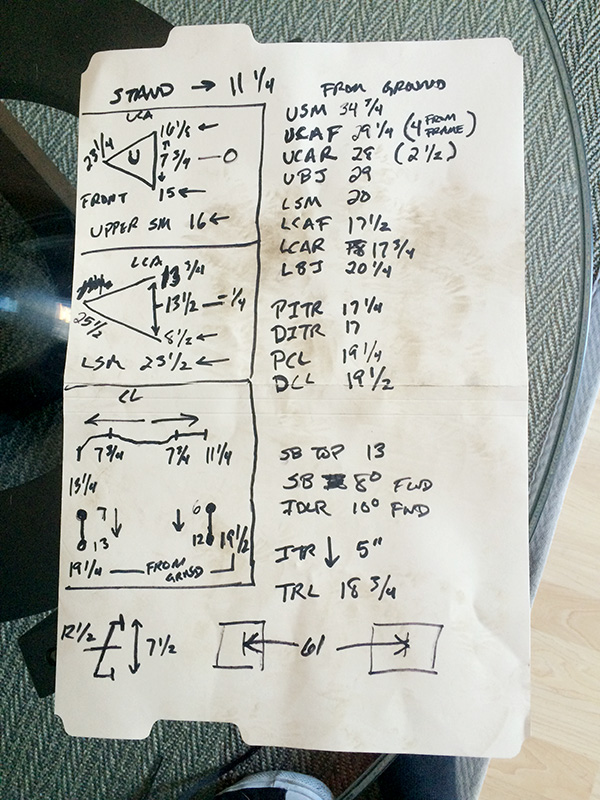

Speaking of determining ackermann, I've decided to take the plunge and order the Performance Trends Suspension Analyzer software. So, before I left for the day, I made a bunch of strange measurements that should hopefully be everything I need to model the front suspension. The hope is to figure out ackermann and make some revisions to the upper control arm mounts for better geometry.

Fingers crossed that next time I have a Camaro that steers again!

My centerlink's not level with the car on blocks and the wheels at full droop. Opposite angle as yours though, haha. went out and took a couple pics, maybe they'll help. I'd put the new stuff on, drop it on the ground and see where you are.

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/012_zps4tm8fjj4.jpg.html] [/URL]

[/URL]

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/013_zpsuza2ipti.jpg.html] [/URL]

[/URL]

In reply to NOT A TA:

That is helpful. My pictures are at ride height, btw. Evidently, GM wanted to use as many Pitman arms as possible on F-bodys. Someone must have had stock.

Firebirds got a dropped Pitman arm, as seen in your pictures. V6 Camaros got a dropped Pitman arm, their own idler, and their own centerlink - all of which are hard to find. V8 Camaros had a straight Pitman arm, different idler, and different centerlink.

Evidently, despite doing my homework, I ordered the V8 centerlink and a V8 idler arm, which is why my stuff doesn't work right. I found what I hope to be a straight, 7" V8 Pitman arm that should correct everything... fingers crossed.

I went out and checked my Camaro, it looks just like yours.

Centerlink

Pitman arm

Idler arm

There is some good info in this thread on steering linkage parts, maybe it will help. http://www.nastyz28.com/forum/showthread.php?t=209689 They show a drop idler arm from a FB. Once you figure it out, then I will know what will fix mine as well. ![]() Edit: my car came with newer steering parts, so I'm not sure exactly what's on there.

Edit: my car came with newer steering parts, so I'm not sure exactly what's on there.

In reply to 81cpcamaro:

My plan is to put the Speedway idler arm, and my "new" straight Pitman arm on the centerlink I bought and see where things end up. I'd really like to the inners to be even because it will impact bumpsteer.

Glad to see I'm not alone here.

This may be hard to believe but those holes seem to have been made almost at random. One of the things we did with almost all our street stock chassis, both Camaro stubs like yours and Metrics, were drill new mounting holes for either the steering box, idler arm, or usually both. We would also weld in thick wall tubing for the bolts to pass through instead of just the holes in the frame rails but I imagine you aren't as worried about collisions.

Besides having the center link level, if you are playing around with the mountings try and get the two arms to swing in the same arc. That will help keep bumpsteer in check.

Every time I see pictures of a performance car with pitnam arms, drag links, center sections, and idler arms I immediately think of that guy in my backyard when I was a kid trying to find our septic tank with divining rods. It may work but damn if I can figure out why and can't help but think technology provides a better way. ![]()

Wally wrote: Besides having the center link level, if you are playing around with the mountings try and get the two arms to swing in the same arc. That will help keep bumpsteer in check.

Smart idea. I heard there is a lot of slop in the mountings too, so I think that with the right Pitman arm I can get things pretty well together.

nocones wrote: Every time I see pictures of a performance car with pitnam arms, drag links, center sections, and idler arms I immediately think of that guy in my backyard when I was a kid trying to find our septic tank with divining rods. It may work but damn if I can figure out why and can't help but think technology provides a better way.

Fair point there. Truth is, it can be made to work pretty well, and I'm at the point where I need to get this car out and running. A rack could be in my future, but it has to stay in the future for now.

Wally wrote: This may be hard to believe but those holes seem to have been made almost at random. One of the things we did with almost all our street stock chassis, both Camaro stubs like yours and Metrics, were drill new mounting holes for either the steering box, idler arm, or usually both. We would also weld in thick wall tubing for the bolts to pass through instead of just the holes in the frame rails but I imagine you aren't as worried about collisions.

The idea of passing bolts through a tube is actually a good idea. You will be able to get a more consitent torque on the fastners with out the frame flexing in. I run a panhard bar made by Maximum Motorsports for my Mustang and to keep from bending the frame walls they use tubes wellded to a plate passed from one side of the frame butted to the other to leep the frame from colasping when you torque down the fastners.  This gives you some idea of what mine looks like. Lousy picture for an example sorry.

This gives you some idea of what mine looks like. Lousy picture for an example sorry.

Okay, attention people who are smarter than me.

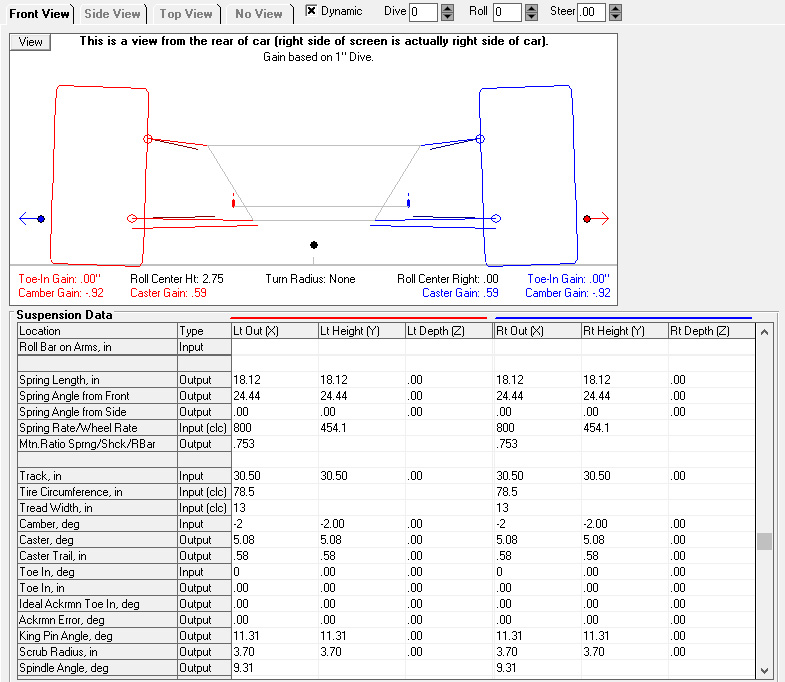

I did my best to translate my measurements into the software, but I did adjust a few numbers. For example, I've lowered my upper control arm mounting points because I will be doing that in the near future.

I also lowered my inner tie rod connection point at the centerlink because the tie rod has a bend in it, if that's not right let me know.

I've also probably not quite measured the center of the ball joints per the software spec, so I'll adjust when I get up there next.

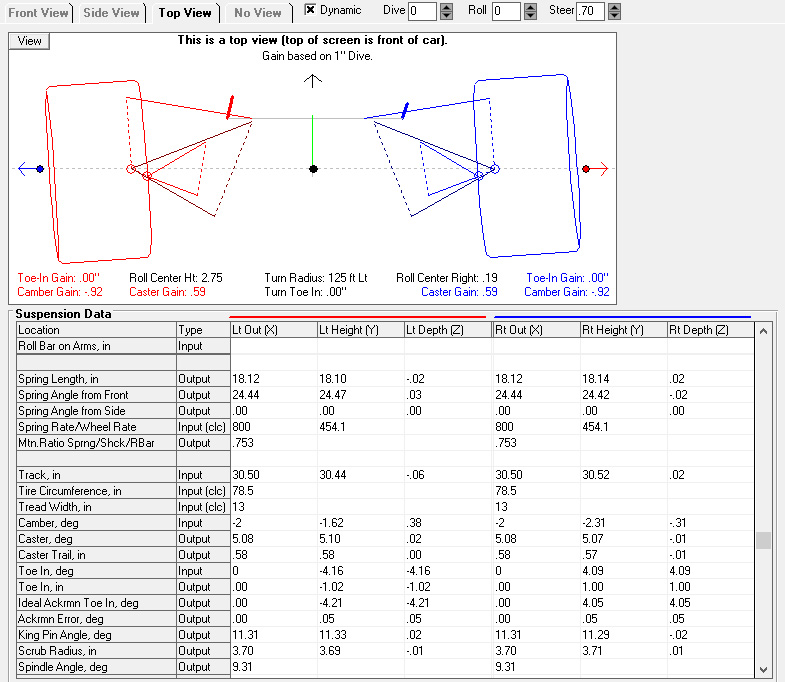

Basically, I'm trying to figure out where to mount my outer tie rods on the steering arm for the best ackerman setting. Performance Trends software has a spec called "ackerman error" which is defined as "Ackerman Error is the difference in degrees between the "Toe In, degrees" and the "Ideal Ackerman, degrees" above." - http://performancetrends.com/PDFs/SaManl4.pdf

If I read this correctly, I assume you'd want the smallest amount of error possible.

Going off of that, I started to lay things out. I set the outer tie rod attachment point 2 inches forward of parallel. You can see it in the images.

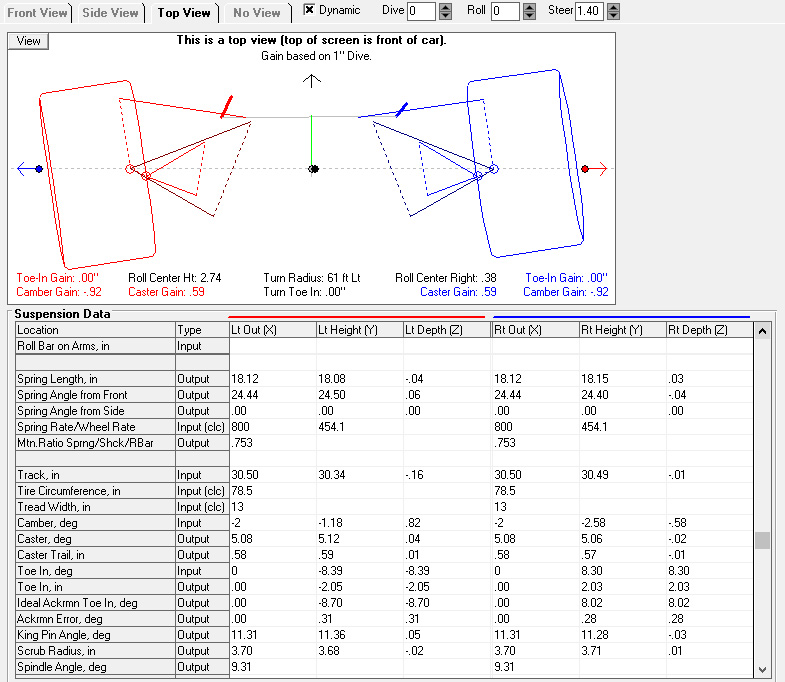

Here is the car at ride height, wheels straight, etc, as a baseline:

Next, I turned the wheel of the car to see the readout. This is "halfway."

Ackerman error is .05, which seems really good.

Ackerman error is .05, which seems really good.

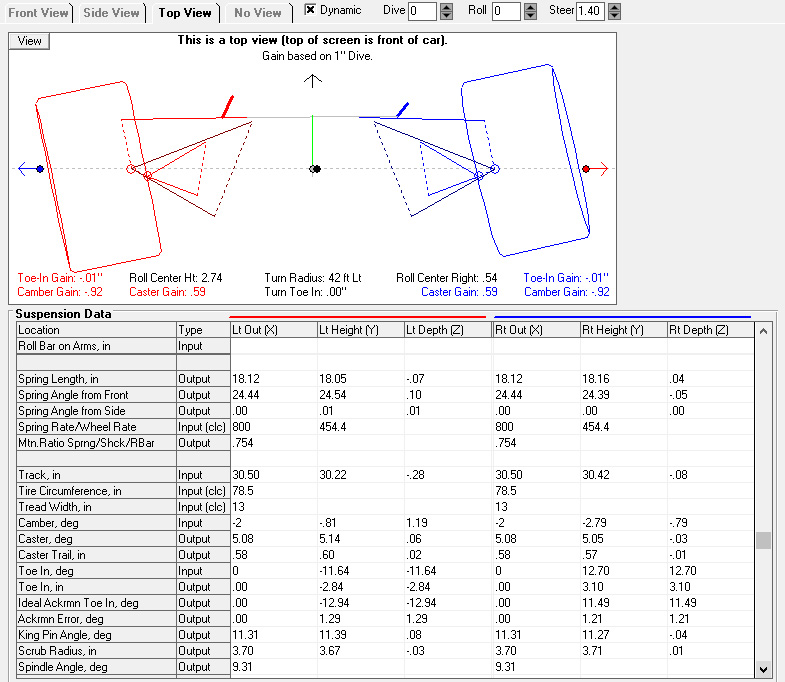

Next, I turned the wheel the rest of the way.

Ackerman error is .31, which I guess is still okay?

Ackerman error is .31, which I guess is still okay?

Finally, I set the outer tie rod ends to parallel and went to full steer.

Ackerman error is 1.29 at it's worst, which makes me feel like parallel is bad.

Ackerman error is 1.29 at it's worst, which makes me feel like parallel is bad.

It's really hard to see if the setting are right without some more lines drawn. I can't really tell if the inside tire is turning further at my better setting.

What do you guys think? Does this make any sense?

I wish I could help you there, but I'm still trying to figure it out myself. Check your email, sent some info that might be helpful.

You'll need to log in to post.