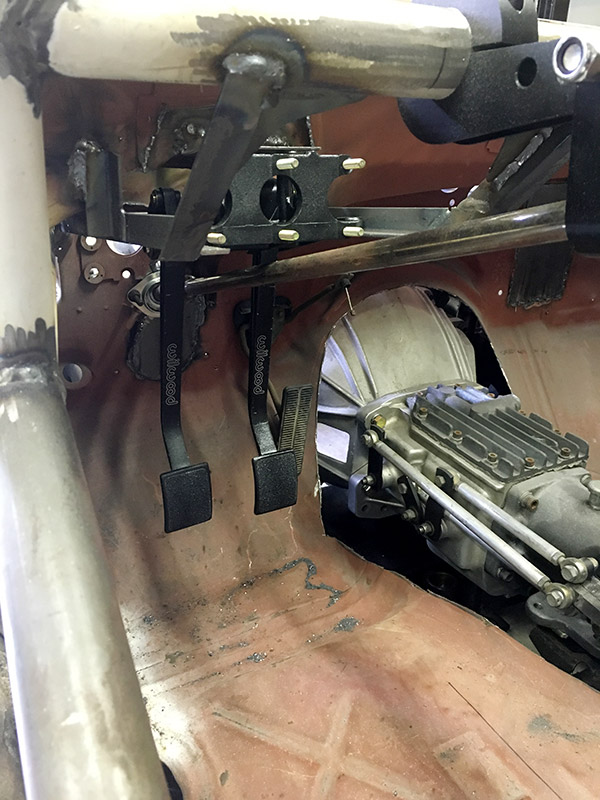

Got a text from Larry... pedals are just about done.

Looking good. I would move the gas pedal back, closer to even with the brake/clutch pedals. I did that with the stock pedal in my car.

81cpcamaro wrote: Looking good. I would move the gas pedal back, closer to even with the brake/clutch pedals. I did that with the stock pedal in my car.

That is the plan.

Moving day!!!

I ran over to Larry's today and picked up the Camaro. There are still a few things left for him to do, but he needed his garage back to get the Corvette ready for SCCA Nationals.

We loaded up the car and had a fairly uneventful tow to the house. This was the moment it came off the trailer.

The neighbors seemed unimpressed.

But, for the first time ever, I got to do this:

Looks happy, don't it?

And my reward(s) for a job well done.

Gimp wrote: The neighbors seemed unimpressed.But, for the first time ever, I got to do this:

Looks happy, don't it?

And my reward(s) for a job well done.

Lunch and those bottles are full?

Great milestone and a sweet shop.

So yeah...

Been quiet on my end as moving into the new house meant working on the new house and not necessarily the car. I have found a few moments here and there to sneak out to the garage, but started on some bigger stuff last night.

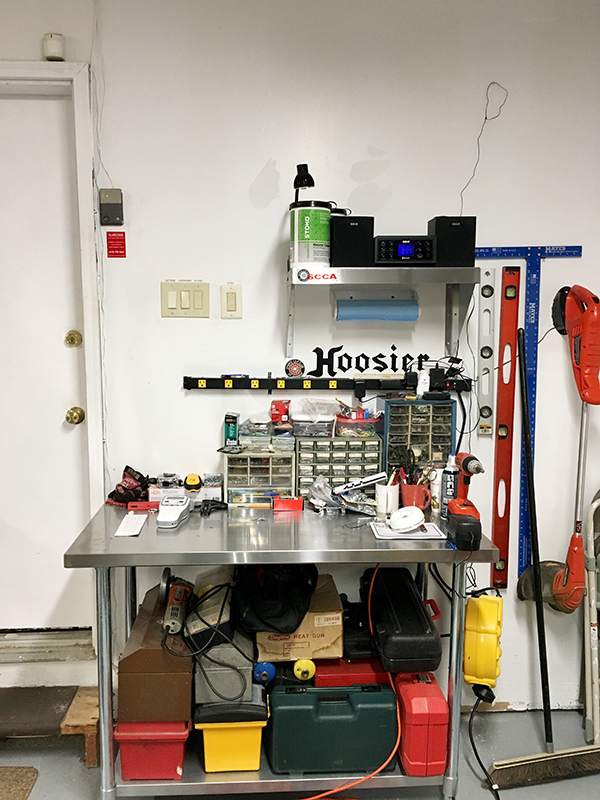

But first, garage improvements!

Let there be light: I added two more overhead LED shop fixtures, and converted the existing fluorescent fixtures to LEDs.

Huge difference in the amount of light in the garage. Pretty sure I can tan in there now.

I built a quick shelf in the back of the garage to store some parts:

I also got a stainless steel workbench/shelf combo from Lowes, which quickly got covered in stuff like a good workbench does:

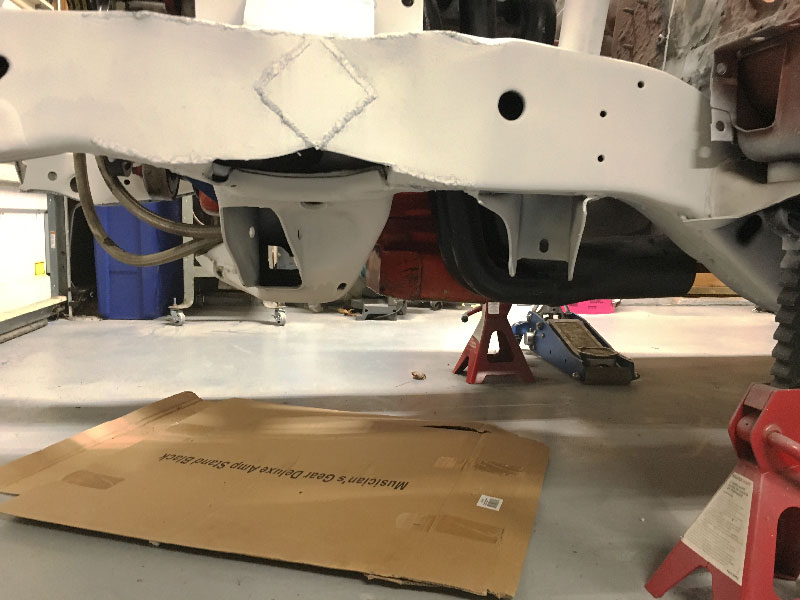

So on to the car. The car had to be a roller to get it into the garage, but it's coming back apart again for a few reasons. So up on stands it goes.

Astute readers will notice the cage has a little more paint. I have been priming the areas that are "done" to keep corrosion down.

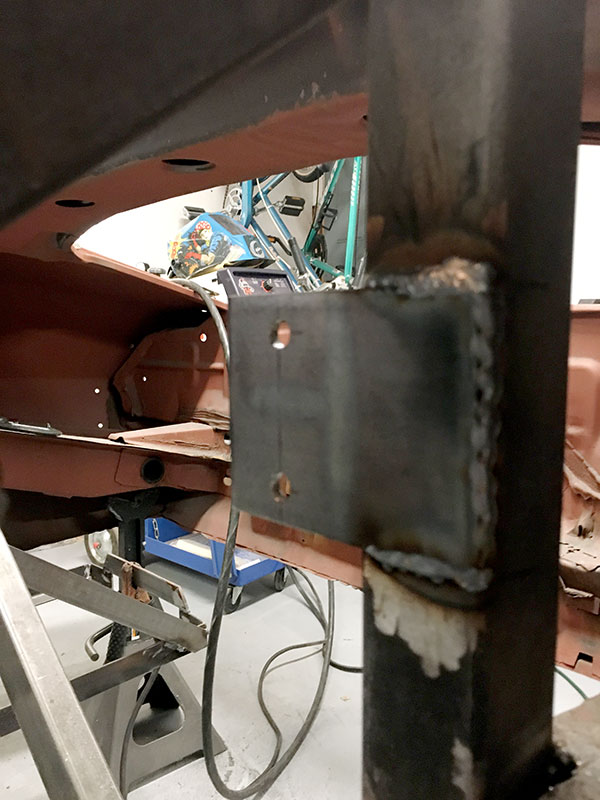

So now, the actual work. Back when Joe and I discovered the joy of a plasma cutter, things went a little too far.

The metal part of the dash was cut out of the car, and that wasn't a legal mod. All fixed (thanks to some donor sheet metal).

It still needs to be metal finished, but it is in there. This was great practice, as the next move will be to replace the passenger side floor pan.

Good to have the car at the house, makes it easier to get stuff done. The end is in sight, can't wait to see it out there.

Plasma cutters are a bit of fun, real easy to go "too far". If I build another CP car, I will only cut what I have to, just to be safe. Just not sure what I am going to do yet. Since getting and riding the motorcycle, which is quite enjoyable, I am less certain on what I want to do now.

81cpcamaro wrote: Good to have the car at the house, makes it easier to get stuff done. The end is in sight, can't wait to see it out there. Plasma cutters are a bit of fun, real easy to go "too far". If I build another CP car, I will only cut what I have to, just to be safe. Just not sure what I am going to do yet. Since getting and riding the motorcycle, which is quite enjoyable, I am less certain on what I want to do now.

As long as you remember how to codrive, I've got you.

Ground down the welds and primed last night.

I'll still have to go back and skim some body filler when I get to that point, but I'm pretty happy with how the repair turned out.

Gimp wrote: So now, the actual work. Back when Joe and I discovered the joy of a plasma cutter, things went a little too far.

Yeah, we got to the point where we joked about taping the SCCA rulebook onto the plasma cutter...

But I did take a rather significant amount of weight out of the (now replaced) core support!

The funniest part of it is that I (now) fully expect a few hundred pounds of lead to have to go in the car!

Yeah...

Hm, I am interested in the flourescant to LED conversion. Will have to get details sometime for my shop.

This is what I used to retrofit the old lights: https://www.amazon.com/gp/product/B00SSNPGSC/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

The new lights are on sale at Lowes: https://www.lowes.com/pd/Utilitech-Pro-Strip-Shop-Light-Common-4-ft-Actual-6-5-in-x-48-in/999911231

Just another quick update. One of the many reasons I'm glad I can just walk out to the garage and get some work done.

First, I cleaned and painted the front subframe and new modifications to it.

Then, I started to replace the bits of floor that had rusted out. The car had leak t-tops, but the damage was minimal.

I still have one more section to fix, then grinding, but ran out of time. That sheet metal in the floor, after the rust damage and sand blasting, was awfully thin. Total pain in the ass to weld up. Good thing I have grinders.

Post Thanksgiving update. Having a car, in your own garage, on a long weekend, is the best thing ever.

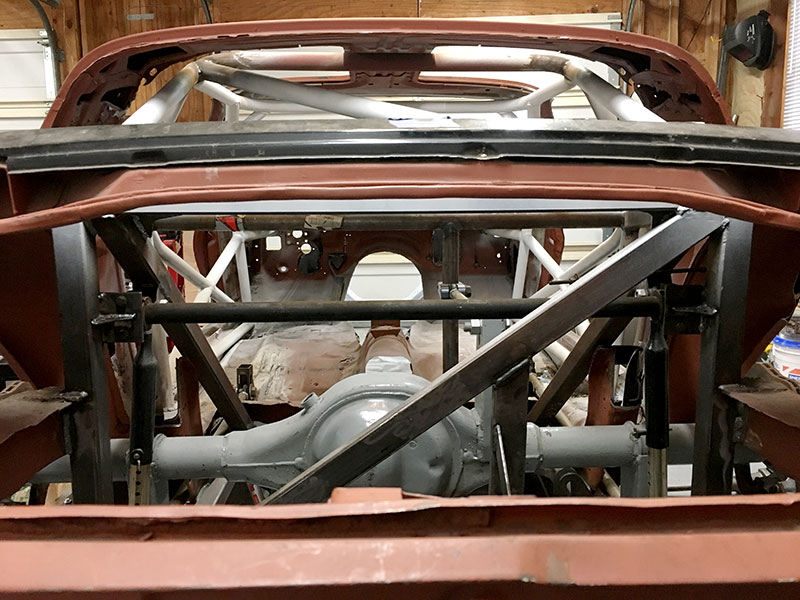

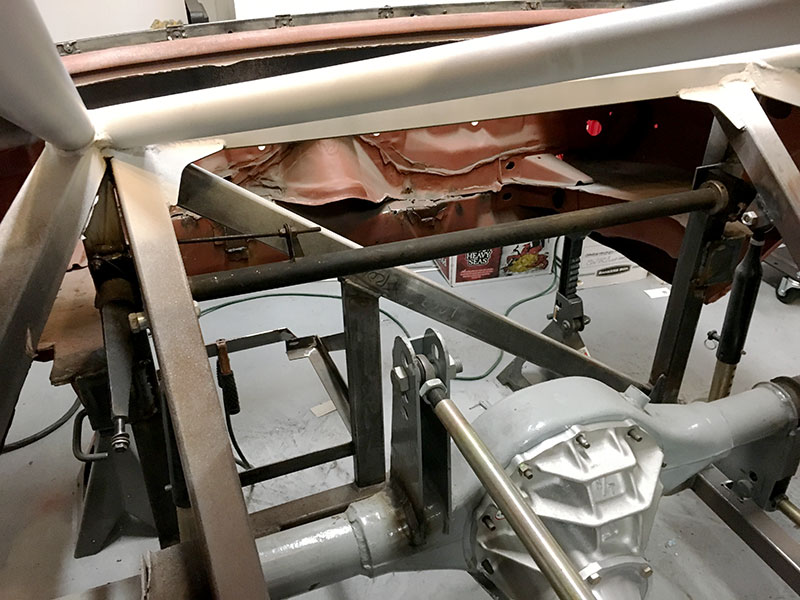

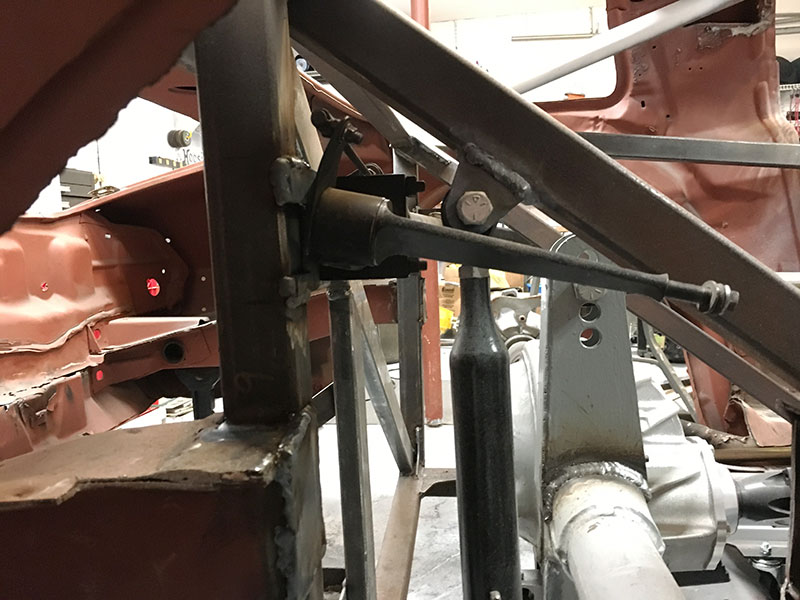

Started the weekend with the exciting bit - installing the rear sway bar. I picked up a very cool, very trick blade style sway bar for the rear from another racer, but I had to fabricate the mounts. I thought I'd have lots of room in the back considering how much of the car isn't there anymore, but packaging wound up fairly tight.

Here are the mounts. One is notched for clearance (see below).

Braced on the back.

And the bar bolted in.

The driver's side arm is standard.

But the arm on the passenger side is the blade. The notches in the bracket are to allow for clearance of the adjustment mechanism. It's tight, but it has just enough room.

Right now you just adjust it with a wrench, but I'm going to have to do the in-car adjuster, if only for the cool factor.

While I was back there, I capped off the frame from where it was cut away.

Before:

After:

After:

The next day I tackled rust repair. This sucked. No other way to put it. The floor was rusty and thin from the t-tops, and was made thinner by sandblasting. It was hard to get even a quick tack without blowing through the factory floor. I knocked the high spots down on the welds, but left the bulk there for strength. I'll toss some seam sealer over it and bed line the floor, and never think about it again.

And then yesterday I spent some time cleaning up the firewall. I'm not really trying to "smooth" things, but make them at least "race car pretty." So any holes that I'm not going to use have to go bye bye. I guess CAM is out of the question now, since I ditched the wipers.

I'll body work it later, but at least it's done for now.

Quite the weekend, but I'm super happy with the progress.

Crossposting this from another site to get your feedback:

17.2.C. The chassis, frame, or subframe may be notched or cut and brackets may be added for the purpose of attaching alternate suspension, steering, or drivetrain components except that the firewall may not be modified for engine block or cylinder head clearance. Holes may be cut to provide clearance for authorized suspension, steering, and drivetrain components through their entire range of travel. Clearance between the modified chassis, frame, or subframe and the suspension, steering, and drivetrain components is not to exceed 4.0” (101.6 mm). Additional structure may be added in order to attach allowed components to the chassis. Relocation, notching, or cutting of the chassis, frame, or subframe for tire clearance or moving the wheels inboard is not allowed. Replacement of inner fenders or wheel wells to enable wider wheels and tires is allowed. I'm not trying to rain on the parade here, but I really don't see removing those 2 big chunks of the frame rails as being legal. Notching it for clearance, absolutely. But not removing a section. I know Brian Hobaugh had it done on his car, but I also know a lot of folks in the class thought it was wrong. I just don't want to see you get it done and go to Nationals, only to get protested. My car sits pretty low, and I am not in danger of touching the frame rails. I could go lower, and still have clearance.

I'm glad you brought this up. Before I say anything else, I have to two pieces of frame rail on the shelf, and I could put them back in if necessary.

I spoke to several people, including (but not limited to) Brian about the modifications I have made. They have all said that while taking things to the limit, it's not illegal. My shocks run straight through the middle of the frame rail, and my sway bar end links land directly on top of the axle tubes. If you use this bit of the rule as a guide:

"Clearance between the modified chassis, frame, or subframe and the suspension, steering, and drivetrain components is not to exceed 4.0” (101.6 mm)."

I'm in the clear.

I know this is going to be a sore spot for some people. That's the reason I've kept the bits I've removed. All of that said, I will likely bring the car to Nationals in this configuration (unless a bunch of people come out of the woodwork and make very strong case not to). In some ways I welcome a protest so we can clarify the rules. Hobaugh had done it to his car, and while a lot of folks thought it was wrong, no one threw paper. I'm willing to be involved in a protest to clear things up, but I think I'm within the scope of the rules.

Got a little bit more done over the holiday.

First, I messed around with the rear flares a little bit. They were always a little too long for the factor wheel well.

The flare is fairly consistent in shape in the middle, so I cut a little section out.

That got things looking a lot better. I can probably narrow it a little more, but until I get the new wheels and tires on the back, it's best to put down the saw.

I also got a pretty awesome Christmas present from Kate (see last photo), so I got to work on building some structure to put it in place. I removed both the front and rear bumpers years ago for weight reduction. Because the front clip is a one piece, I didn't need to put anything back. The rear was a different story. So I made this:

Pretty much all 1" square stock and flat stock. Not heavy at all, but bolts to the important bits.

Hopefully I won't get into any accidents on course.

It bolts up nicely, and once I trim the plates there will be plenty of adjustment in it.

And as for the present...

https://www.youtube.com/watch?v=AwkdKfkncok

Dusterbd13 wrote: Where did you get the flares?

I bought the flares used from someone on a different forum, but I believe they are from http://www.showcars-bodyparts.com

Another racer recently ordered full quarters from them and they appear to be the same deal.

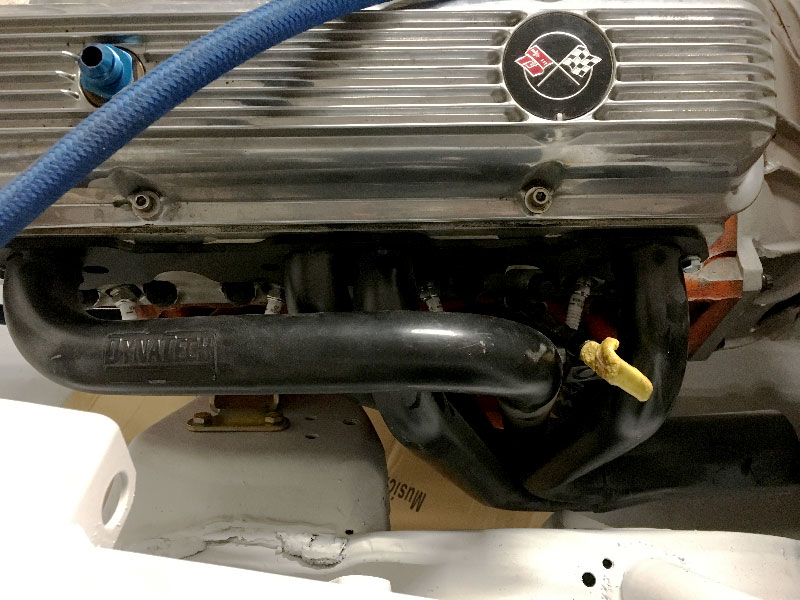

Small (but kinda big) update over the long weekend. The real motor is in (for now).

Kate and I, with minimal cussing (and not much directed at each other) stabbed the motor in on Saturday.

Up until now I have been using a mock up block, but since the next steps include fabricating the exhaust (where tolerances are going to be very tight) I thought it best to install the real thing - and I'm glad I did.

I'm using a set of Dynatech 701-2100 headers, which are for this chassis. The drivers side has always fit really well.

Especially in terms of ground clearance.

The passenger side, on the other hand, was a very different story. If you read back earlier in this thread, you'll see that Larry had to modify the header to raise it. Well, when I tried to install it, the collector hits the floor pan by just enough to make bolting things up impossible. I can, within the rules, cut the floor for clearance (and I will), but had I done this on the mock up block there is a chance I would not have known until well down the road.

Saturday was the only work day, as Sunday was spent prepping the garage for an electrician that came yesterday. But, I do now have a sub panel with two 240 receptacles, a dedicated AC circuit to help cool the garage, and 3 quad gang boxes giving power all along the wall. A vast improvement from the single outlet the garage had before. I spent the rest of yesterday hanging sheet rock and insulating the wall and should be done by next weekend. Things are starting to shape up in the new garage.

Hey, that engine looks familar. ![]()

Looking good, drivers header clears the plugs quite well, way better than the headers did in the El Camino. The electrical outlets will help out a good bit. Which reminds me, I need to get a 220 outlet in the garage. I have the line in the box already (used to run to a hot tub), so I just need to actually take the time and do it.

81cpcamaro wrote: Hey, that engine looks familar.Looking good, drivers header clears the plugs quite well, way better than the headers did in the El Camino. The electrical outlets will help out a good bit. Which reminds me, I need to get a 220 outlet in the garage. I have the line in the box already (used to run to a hot tub), so I just need to actually take the time and do it.

I did have to rotate the dipstick a little, but your "custom" dipstick handle fits well.

You'll need to log in to post.