I have to ask, did you do the tack welds in the living room?

mazdeuce wrote: I have to ask, did you do the tack welds in the living room?

You know, after I took those photos it kinda looked that way.

In reality the welding was done in my mom's overloaded one car garage where I store my welder and some parts.

So I need some expert advice.

Getting ready to order up the center section and I need some guidance. Car is an autocross car that will see pro-solo launches. Target HP for the motor is 500-600hp. Vehicle weight will be 2700lbs.

So, this is what I "need" * aluminum housing * 4.86 gears * 31 spline TrueTrac * 1310 yoke

I'm looking for recommendations on vendor, and then on some of the other "bits" that go along with ordering these things. For example, do I want a forged yoke or an aluminum one? Do I want an aluminum pinion support or iron? What are "pro" gears, etc.

31-spline TrueTrac? As in the same one I just installed in the Ford 31-spline 8.8" rear on my S197 Mustang? If so, I can recommend a damn good shop/vendor for you.

Sky_Render wrote: 31-spline TrueTrac? As in the same one I just installed in the Ford 31-spline 8.8" rear on my S197 Mustang? If so, I can recommend a damn good shop/vendor for you.

Please do.

DILYSI Dave wrote: Currie is probably a good one-stop-shop.

I'll have to check them out. I'm also considering Quick Performance ( http://www.quickperformance.com/Ford-9-Strange-Aluminum-Complete-Center-Section-Third-Member_p_16022.html )

Gimp wrote:Sky_Render wrote: 31-spline TrueTrac? As in the same one I just installed in the Ford 31-spline 8.8" rear on my S197 Mustang? If so, I can recommend a damn good shop/vendor for you.Please do.

http://www.jpcracing.com

Not much of an update. Got the holes opened up to the proper size and checked my measurements with a tire on the rear end. Everything is looking good so far, so I ordered up my upper and lower links based on my rough estimates of lengths. The nice part about the circle track stuff is that it's so cheap I can always get close and try again.

Got out of my basement yesterday to let some of the new parts meet the old parts. The hardest part of this build has been "building remotely" in the sense that I can't just walk out to the garage to measure something. I have a notebook full of measurements and information on the car so I can work on things when home.

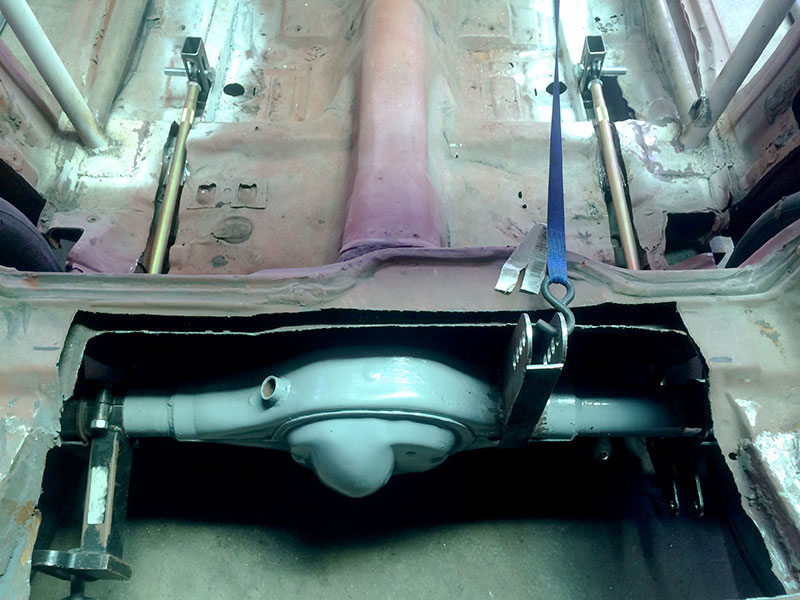

The biggest challenge (the placement of the rear end brackets) got a chance to be put to the test this weekend, and it passed with flying colors. The lower link brackets line up perfectly with the frame rails, so I could comfortably start cutting holes in the frame to pass the lower links through. I also measured for my forward lower link mounts, per my suspension modeling software, and that should all drop right in place.

I've got a little more cutting to do, but soon the car will have a real rear suspension for the first time in a long time.

(The upper link, aka strap, is a little long, flexible, and at a bad angle, but I'll change that later)

This was probably the most unnerving part - cutting into the frame. The hole is small now, and will be opened up as needed for suspension travel.

And finally, the rear tire fitment with the wheels and tires mounted up on the proper rear end, centered in the frame. I still need to cut for compression travel, but I'm happy with how "tucked" the 14" wide rear tires are. Hopefully I won't have to space them out.

Brown Santa dropped by yesterday...

I opened the box and got a chuckle out of how they packed it to protect it.

But it sure did protect this beauty.

81cpcamaro wrote: Dang, that diff is a bit smaller in diameter than my GM 8.5 TrueTrac.

That looks more like an Eaton Posi (clutch-type) to me.

The TrueTrac for my Ford 8.8" was like twice the size, too.

Got another major component of this build on Friday, but it's a little different than what you expect - the tow vehicle!

I'm now a suburban cowboy. It's a 2014 Z71 5.3L Doublecab with the "Allstar" and "Plus" packages, as well as the built in trailer brake and a wireless router! Only 200ish miles on it so far, but it's getting around 18mph in mixed driving and getting better.

I did have to get rid of the WRX for it, but that just means I'll spend more time commuting in the wife's Honda.

I thought I would need the truck a lot closer to the car being done, but far too frequently I need to haul big and/or dirty parts for the project. With the rebates, etc, timing just made sense.

It was a little spendy, and very strange to drive, but it will help the project reach completion and future events.

I'll have some real updates after this weekend.

Just got back from a quick trip, and it was rather successful.

I got the top of the frame rails, and (most of) the top of the subframe connectors cut and cleared for the lower links. I forgot to bring my Sawsall with, so I'll have to finish that job next time.

Either way, I was able to tack in my lower forward mounts, square up the axle, and install the lower links. Next step is the upper link, but it's looking good.

Also, the truck averaged 21mpg on the ride out there. Not bad all around.

You'll need to log in to post.