Punch list in the engine bay is beginning to drop just a bit. The tiny details always take longer than expected, so I'm using whatever free minutes I have to just knock them out and leave the big stuff for when I have more time available.

I added some engine oil, and immediately saw some drips at the oil pan. Fook. The brand new copper washer isn't sealing the drain plug, even after snugging it down just a bit more. I'll probably just drain the oil, teflon the bolt, and snug it all back up at this point. On to the next.

Clutch slave cylinder hard and soft lines were connected and tightened up. It's tight in the trans tunnel so that was a pain and I know it's going to be a struggle to bleed later.

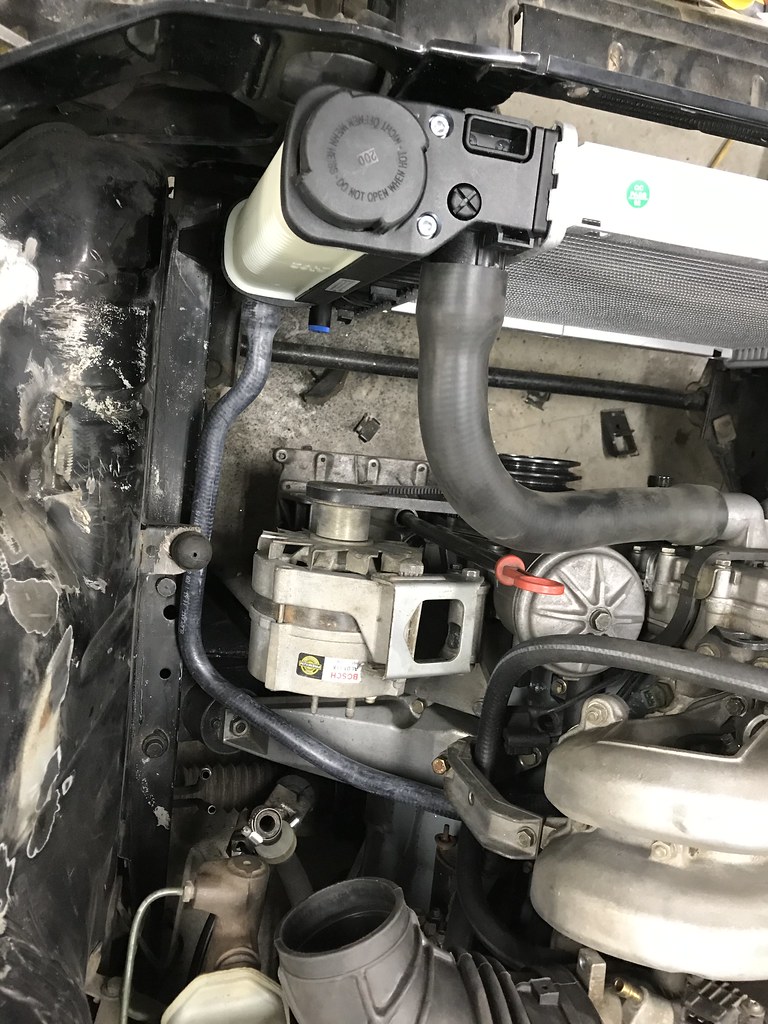

At this point I'm not taking pics, just trying to get the little things. Tighten alternator belt and bolt check.

Engine harness installed so I can figure out what needs moved compared to an e30 engine bay. After a few hours of head scratching and internetting, I've figured out where to splice in the stock e21 engine connector, and that the fuel circuit needs one adjustment made to accommodate a proper fused circuit. I've got some Tesa tape to wrap all wires when it's all finished to give an OEM look.

New alternator ground cable in to replace the shagged one. I got this 4 pack of them from ebay real cheap, but with them not being a larger gauge wire like the stock units I'm a bit worried. I have one for the engine ground off the passenger motor mount as well, just need to weld a stud on the frame rail to snug it down.

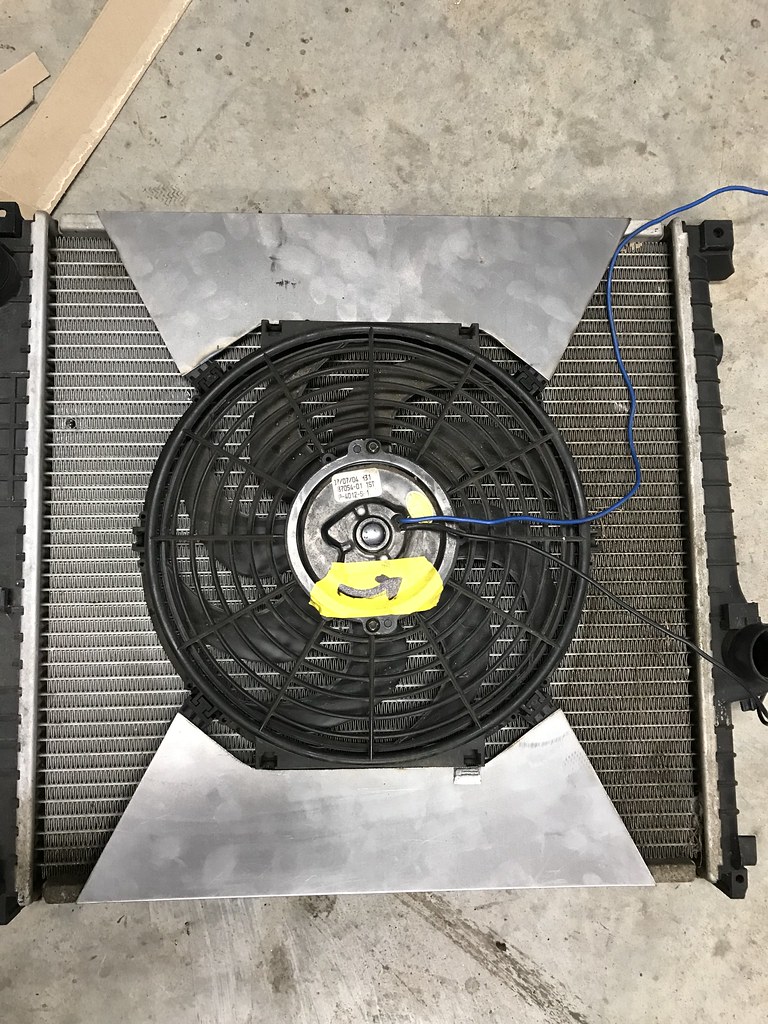

Radiator temp sensor has been installed so the e-fan will kick on when needed. Looks like I need to extend the stock wires a few inches to reach the new location. Waiting on some more uninsulated splicers to roll in before I can get that done. Also hoping to finalize some upper rad mounts Sunday.

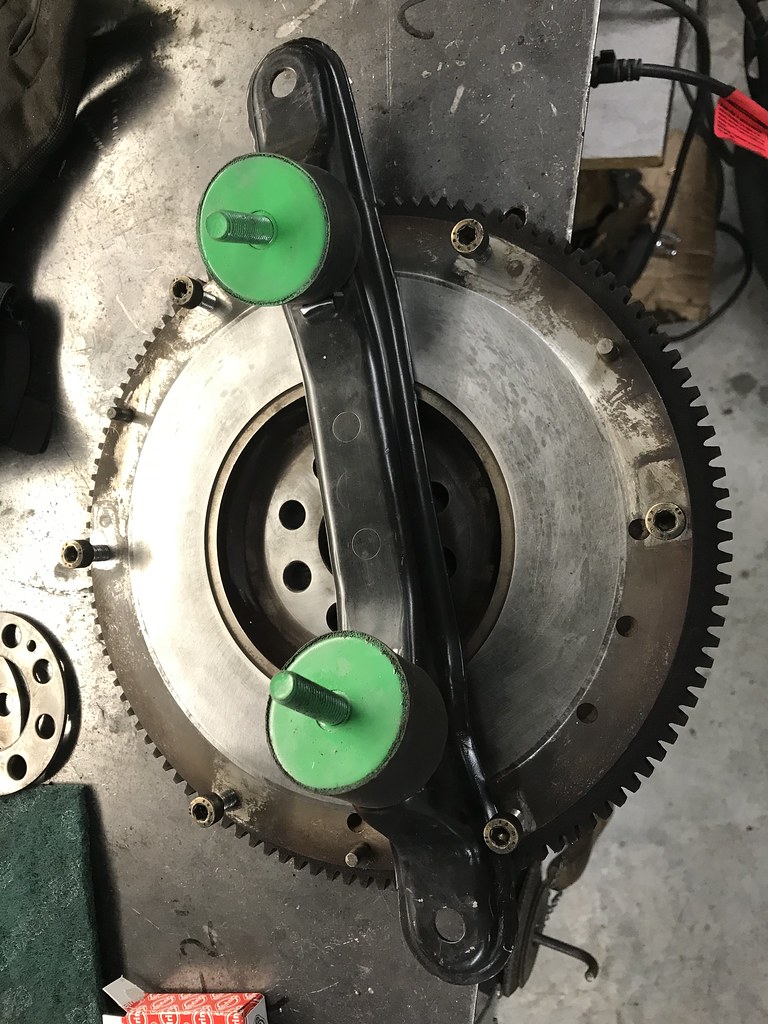

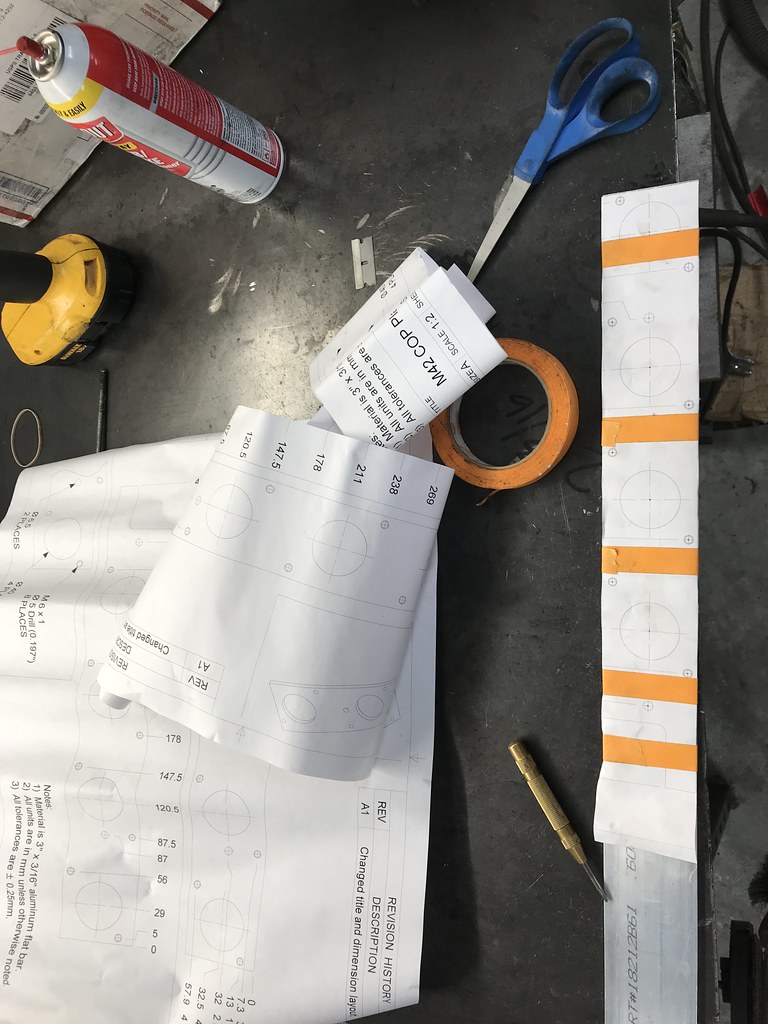

Installed 3 nut style clips in the shifter tunnel so the shifter setup I drilled will bolt in using stock hardware. New shifter should roll in this afternoon so I can get the linkage sorted.

Cleaned up and snatched some hose clamps from the m10 to make sure I don't need to order any or dig through the parts stash.

My new smaller battery will be here tomorrow, so hopefully Sunday I can get a bracket made and start committing to wire harness work. It's an ebay knock off of the pc860 for $34.99 called a Mighty Max Viper VP-600. Could be junk, but it's a smaller footprint than the lawn battery and an exact penny for penny cost.

So, speaking of budget, I am currently at $2809.09 before my $1000 recoup with only a few inexpensive items that haven't made the list yet. I have $190.91 left in the budget which I want to keep as open as possible until it's rolling and driving. There is a massive amount of parts that I ordered "just in case" to save on shipping, and some others that just didn't end up using. Luckily a large percentage of these can be sent back to FCP Euro for a refund/credit if needed.

Anyway, one huge budget hit was going to be a good performance chip. I didn't want to do the $30 ebay chip, but that's what was going to be the only thing I could afford to pick up. Miraculously I scored a SSSquid chip from a R3vlimited forum member along with another engine ground clable and airbox clip for the cost of shipping $3.75! Mike, you friggin rock!

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr Untitled by hatchethairy, on Flickr

Untitled by hatchethairy, on Flickr