gonna go with fasteners and Loctite. used a free printable degree wheel and my reference lathe cut to lay

out the hole pattern. I think I will go up and use my dads drill press tomorrow since mine still isn't fixed ![]()

gonna go with fasteners and Loctite. used a free printable degree wheel and my reference lathe cut to lay

out the hole pattern. I think I will go up and use my dads drill press tomorrow since mine still isn't fixed ![]()

not bad for the limited tools used. once it was mounted I spun it up on the lathe to make sure it spins true, then put red Loctite on each allen head one at a time. done.

not bad for the limited tools used. once it was mounted I spun it up on the lathe to make sure it spins true, then put red Loctite on each allen head one at a time. done.

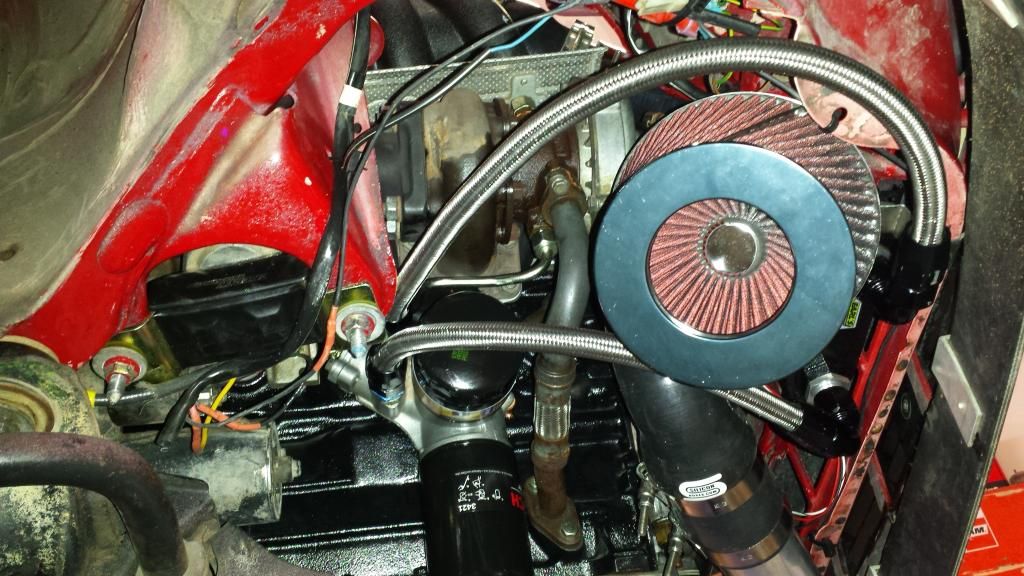

I also tried to mount the oil cooler today but only managed to get the bumper grill cut out

Id like to add that I think externally mounted oil coolers look like hell and I hope that trend dies soon ![]() unless you have a serious reason to put it there (because racecar) just mount it where it can get air. don't screw it to the front of your bumper

unless you have a serious reason to put it there (because racecar) just mount it where it can get air. don't screw it to the front of your bumper ![]()

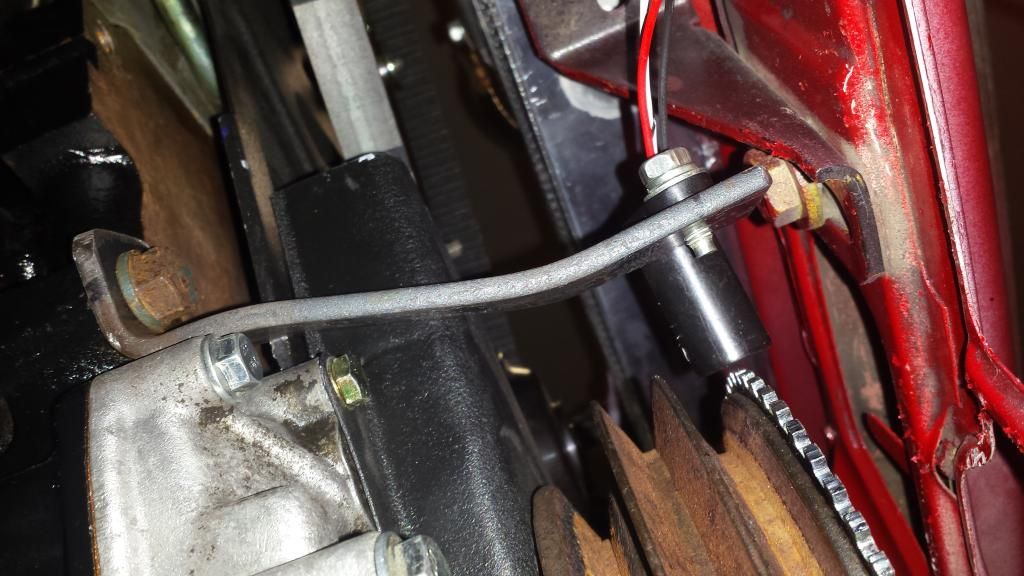

and now the hall sensor bracket is done. no funky welded 2 pc design here. just one solid piece of 3/8 steel with a few bends and a couple holes.

Is that a hall or a "VR" sensor?? My understanding is VR sensors supply a better/accurate signal or "pulse" than a hall does, but it's output is really weak, leading to interference issues, you have to use a shielded cable, I did that on both my cars (it also had to be mounted about .050" from the trigger wheel). I also used a shielded cable for the 1 window hall in the distributor, it was so close to the coil that it was picking up noise from it and causing false triggers!!

Mine is a hall and yes your right. The DIY harness comes pre shielded so that should help. . . Good to know about the cross talk though as my coil is pretty close to the distributor. . . Might be worth shielding that wire too.

Nice to see this is moving along. I like how you mounted the trigger wheel. I was thinking about useing the divider chip and hall sensors on the flywheel, but you make it look so simple to use a 60-2, I might go that route. Not like I dont have a couple spare dampers kicking around.

Also, you will have to let me know if you make any changes to the timing table. We have very similar setups, so would be interesting to see what changes you make.

finished up the oil cooler this morning then fired it up to make sure nothing leaks

got the hall sensor gap at .036 hopefully that's not to tight. the wheel spins nice and true on the engine which is good, one of the things I was concerned with and carefull about while doing the fab work. now im gearing up to re wire the ignition pick ups and im questioning a couple things. haven't found much on what pin the signal wire from the distributor goes to as a cam sensor and I still need to pull the thing and make the cup a one tooth.

got the hall sensor gap at .036 hopefully that's not to tight. the wheel spins nice and true on the engine which is good, one of the things I was concerned with and carefull about while doing the fab work. now im gearing up to re wire the ignition pick ups and im questioning a couple things. haven't found much on what pin the signal wire from the distributor goes to as a cam sensor and I still need to pull the thing and make the cup a one tooth.

I did manage to fix my leaking drain plug with a tap/die and replaced the copper washer with a HNBR o-ring. . . . it appears to be holding now. one more small victory ![]()

In reply to 2K4Kcsq:

The connector on the distributor should have these marks and below is a description:

+= Hall power

o= Hall Signal/Trigger

-= Hall Ground

Also, Did you cut up the hall sensor wheel?? Normally a 1 window wheel looks like this:

i haven't cut mine yet. that was just a pic from the megamanual. I know how to hook up the hall sensor, I just cant find any info on where the signal from the distributor or "cam sensor" would go now that im using the shielded pair of wires on the crank sensor. all I have found so far was instructions to wire it into the ms3 expansion board which I don't have. seems to me according to the generic wiring diagram I can just run without the second hall sensor . only using the distributor to fire the coil thru. I'm about to just try that

unless the 5cyl is so weird it has to have that secondary trigger signal for some reason.

You need the "cam sensor" feed because it tells the ECU where 0° TDC of cyl #1 is. Without it, the ecu will fire the plugs on both the comp. stroke and the exhaust stroke (this is called wasted spark and is ok for 4,6 or 8 cyl. engines), more importantly it will fire the injector on both cycles (bad, too much fuel) or depending on the software, fire it on the exhaust stroke (bad because the fuel sits in the port too long)....

PS, I like the engine mounts!!!! are you still running the snub mount? I got rid of mine on both cars, never needed it!

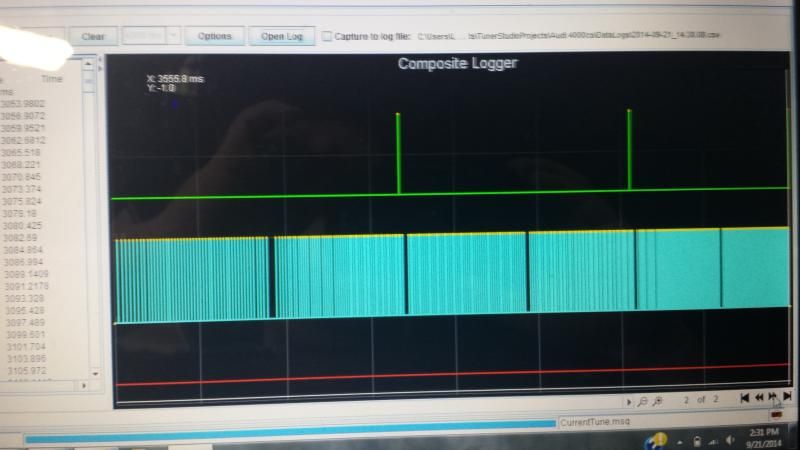

ok thanks for the clarification on that. looks like the configuration for the cam sensor requires me to send the second hall signal to JS10. . . I remember a JS10 on the mainboard just not in the db37 cable which is what I have been trying to figure out this whole time. . . where does that signal wire go? once I figure that out I should be ready to fire again. ![]()

this is the best information I have found yet and its still a little vague ![]()

MegaManual said: Non-MS3X Cam Input If you do not have the MS3X card, but need a cam input then a little more creativity is required. •If you cam sensor is hall or opto, then you may be able to use the 'spare' opto-isolator input on the V3.0/V3.57 mainboard and route it to JS10 for your cam input. This will be documented in the future.

just need to know what the spare opto-isolator input pin is and I can do the rest.

oh and I almost forgot type85 no snub for me either. cant fit it with the intercooler and oil cooler taking up space. and my hall sensor bracket for the crank is using one of its mounting holes now so there is no going back! had to get creative using the timing belt tools though ![]()

I believe this one was setup for a K26, but I have yet to have any problems with it running the K24 that I have. I will have to ask him what he was running it on.

As for the problem you are having with the cam signal, this may help. you have to go the whole way to the bottom. I cant remember which board you are running though.

http://msextra.com/doc/general/tachin-v30.html

thank you for that! ![]() exactly what I was looking for. of course its in the msextra pages, no where else but there lol. my board is 3.57 but it should work out the same. not like I need to remove anything major

exactly what I was looking for. of course its in the msextra pages, no where else but there lol. my board is 3.57 but it should work out the same. not like I need to remove anything major

to my surprise the 3.0 instructions are way different than MS3base/3.57 set it up with the new instructions and still no cam signal. need to get out there this weekend and troubleshoot some more ![]()

What CLT sensor are you using? I am using a factory bosch sensor, and I am having what appears to be noise issues, my temp readings jump around a number of degrees in less than a sec.

I am looking forward to hearing this run! Keep at it, you will figure it out.

im using the clt temp sensor that diyautotune sells. pretty sure its a GM piece. works good, been using the same one on my Datsun for years with no issues. I know im close on the cam sensor. . . swapped the jumper from JP1 to JP3 and I got life on the composite logger for the cam but then had nothing on the crank trigger so im sure I just need one jumper somewhere. . .

one jumper was exactly right! +5v/470r pullup jumper was all it needed to bring that cam sensor to life. it even fired up "first try" after adding that.

now the fun challenge. . . getting a decent tune on 7.5 lbs

soo glad to see it out of the garage finally ![]()

That is great! Glad to hear you got it running. Would love to see/hear it running.

You are really making me think about stepping up to the 60-2 trigger wheel. Right now, the 5 window dizzy is working well, but its on the jumpy side, so my 13psi setup is probably the most it can handle.

mine wouldn't even rev much past 3k on the distributor so I didn't dare take it anywhere up there under load. then again I do have the 7.5lb wastegate spring. I keep forgetting you and eric were/are pushing almost twice the boost I am plus I also have the small valve 2.1 head. . . which then starts to make sense why the tune we are both starting with seems too aggressive for my setup. all I have really had the chance to do is lean mine out and pull back timing and it seems to do better each time. . . the fuel ratios could be off as that K24 im running needs rebuilt. she smokes a bit ![]() and is likely messing with the wideband reading. thinking about switching to my old K26 for now

and is likely messing with the wideband reading. thinking about switching to my old K26 for now

I will say this in regard to the crank trigger. . . every other change I made couldn't even compare to the drastic difference when it fired up on the dual trigger setup. it actually revs smooth now, spools quick and runs strong under load considering the rough tune and still some tweaks needed in the overall setup. still no WOT pulls or anything above 4k but you can tell it just wants to run. ![]()

oh and another thing, I bought a low temp kit (mk3 vr6) from ECS tuning because it was the only 160 thermostat I found that looked like it would work. also came with a 165 fan switch for $35 so it seemed like a decent deal when you compare it to the cost of a vw/audi fan switch

well worth the money. it just hangs out around 172 now vs 203 before. ![]() the vr6 thermostat fits perfect in the 10v block as does the fan switch in the 4k radiator. all this may be old news but I have never heard of/read about anyone doing it so I thought it was noteworthy. next trip to a local junkyard I will snag the vr6 fan switch pigtail but it works fine on spade connectors with heat shrink for now.

the vr6 thermostat fits perfect in the 10v block as does the fan switch in the 4k radiator. all this may be old news but I have never heard of/read about anyone doing it so I thought it was noteworthy. next trip to a local junkyard I will snag the vr6 fan switch pigtail but it works fine on spade connectors with heat shrink for now.

You'll need to log in to post.