Not sure dropping the crank will help you with the pulley, as you're going to take the oil pump with it.

IIRC the NB starter can only use two bolts when it's mounted on an NA trans - check the VIN on the trans to see if it has NA or NB near the beginning. Doesn't seem to cause long term problems.

Do you have pullers? Like, two and three jaw pullers of this style:

That's probably what you're going to need, assuming you can get the jaws on the back side of the pulley.

Actually I take that back; the pulley has threaded holes in it you can use a bar type pulley puller with.

In reply to dculberson :

No threaded holes in this pulley.

Hoping I can modify my puller for the narrow clearance I'm dealing with. It's not a project until you start grinding perfectly good tools.

Calling Keith T......Calling Keith T......clean up on aisle 'not my problem'

Normally that pulley just slides on and off with no force, this one must be wedged in by the broken key in the worn keyway. I dunno how hard the key is -- now that it's out of the car, you could try drilling into the broken off part of the key to relieve some of the tension.

I've had them be a little recalcitrant, although usually getting a pry bar on each side does the trick.

You could weld studs on it or cut grooves in the pulley to seat jaws of a puller. Or drill holes and tap them. It's pretty far gone anyhow. We probably have some kicking around if you need a good replacement.

If pullers don't work, you could use a cutting wheel (maybe a Dremel for the accessibility of the smaller diameter), and cut a groove as deep as possible through the cross section of the gear in between the teeth. Next use a cold chisel in the cut to crack the gear, and relieve the compression on the crank. If you can do it that way, it might save damage to the crank. Maybe even try to cut the gear over the keyway to further reduce the chance of nicking the crank.

If worse comes to worst, I can cut it in two in fairly short order with a chisel.

Takes a special chisel, but it's pretty safe.

Ironically, the chisel design is intended for cutting keyways. LOL

And for those wondering what crackers is talking about .....don't go there....any one that holds a horse's hoof between their knees using a 4.5 grinder to trim said hoof needs to be listened to......out

Keith "just pry harder" Tanner had the hot ticket. Once the motor was out and the alternator and AC brackets were off I had plenty of room. Now that I've done it once I'm pretty sure I could modify some pry bars to get one off with the motor still in the car. Not a huge deal for this time as I now need to replace the oil pump anyway becasue of my ham fistedness, but for the future, it's good to know.

So now I need a new oil pump, new pan gasket, New pulleys (is there a version where they are attached to each other?) and a new key, I already have a front main. I should do a rear main and inspect all of the clutch stuff since the car is out?

Yes. It never gets any easier than on the stand.

Or if the "stand" is working off of the frame on a tilt front end car, that also makes it pretty easy. Working on my timing belt today, should be a piece of cake.

These e the sort of pry bars you want.

I’d do the rear main and at least check the health of a bearing or two. Measure the crank end play, not a strong point of the 99 motor. If you’re changing oil pumps, consider the VVT unit for more volume and pressure if the owner wants an upgrade. Another potential upgrade is a 2001 main bearing support plate and oil pan, which is a bolt-on at this point.

Make sure you get the appropriate timing belt pulley to replace the broken one. There are a couple of different types, but they’re different for a reason.

A lot of these decisions are going to be driven by the car owner. He has a new car and is pretty much over this one. He does want it done as well as is reasonably possible so he can sell it with a clear conscience.

In reply to dherr :

Go ahead and rub it in buddy.

Those cam style pry bars are the business in some cases. Useless in others. I have one of those and a few like mazdeuce has. They both have their place.

Yeah, those upgrades are the decision of the owner for sure. They’re good “while you’re in there” upgrades, but if he’s just looking to unload then they may not add any value.

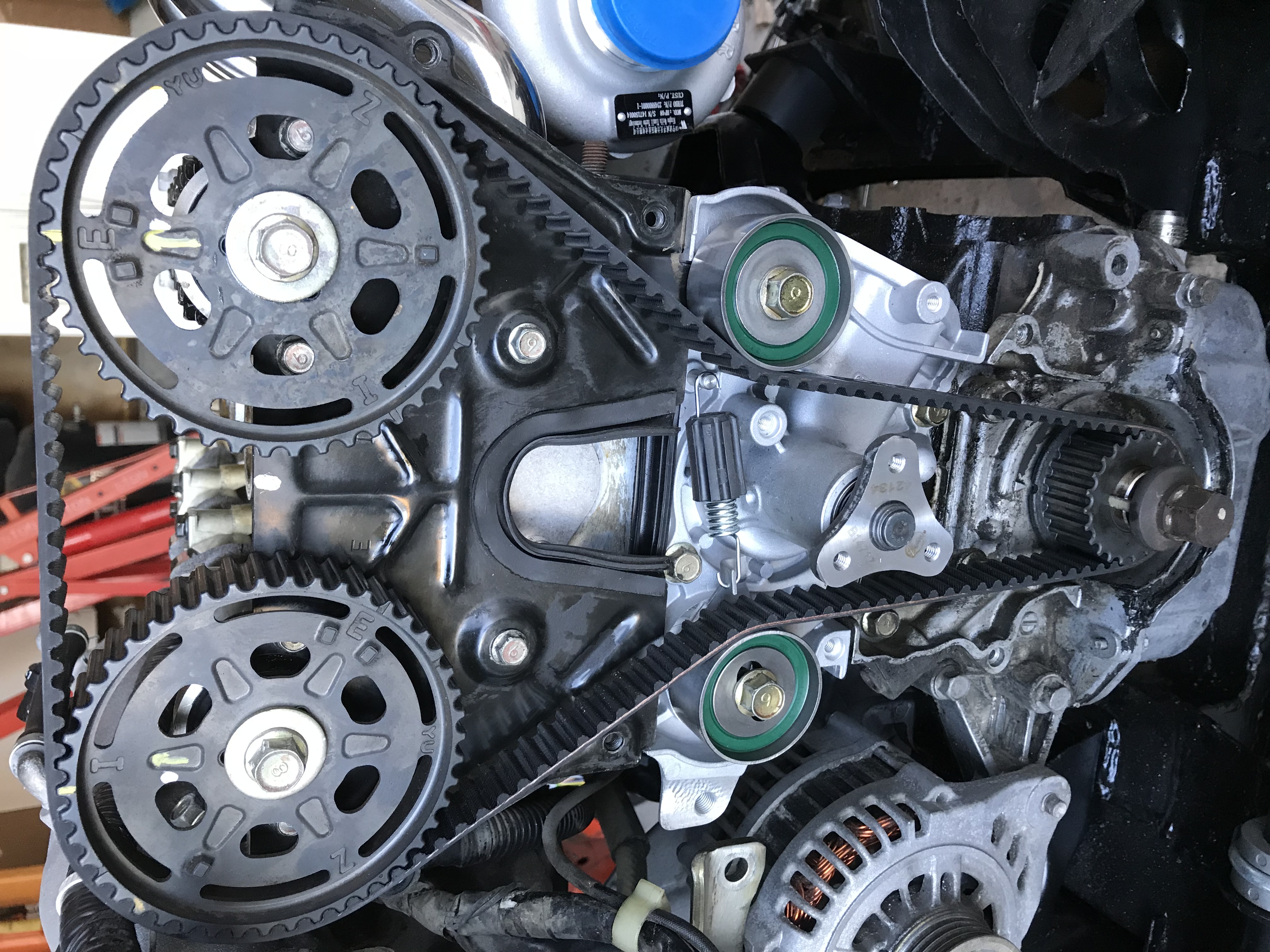

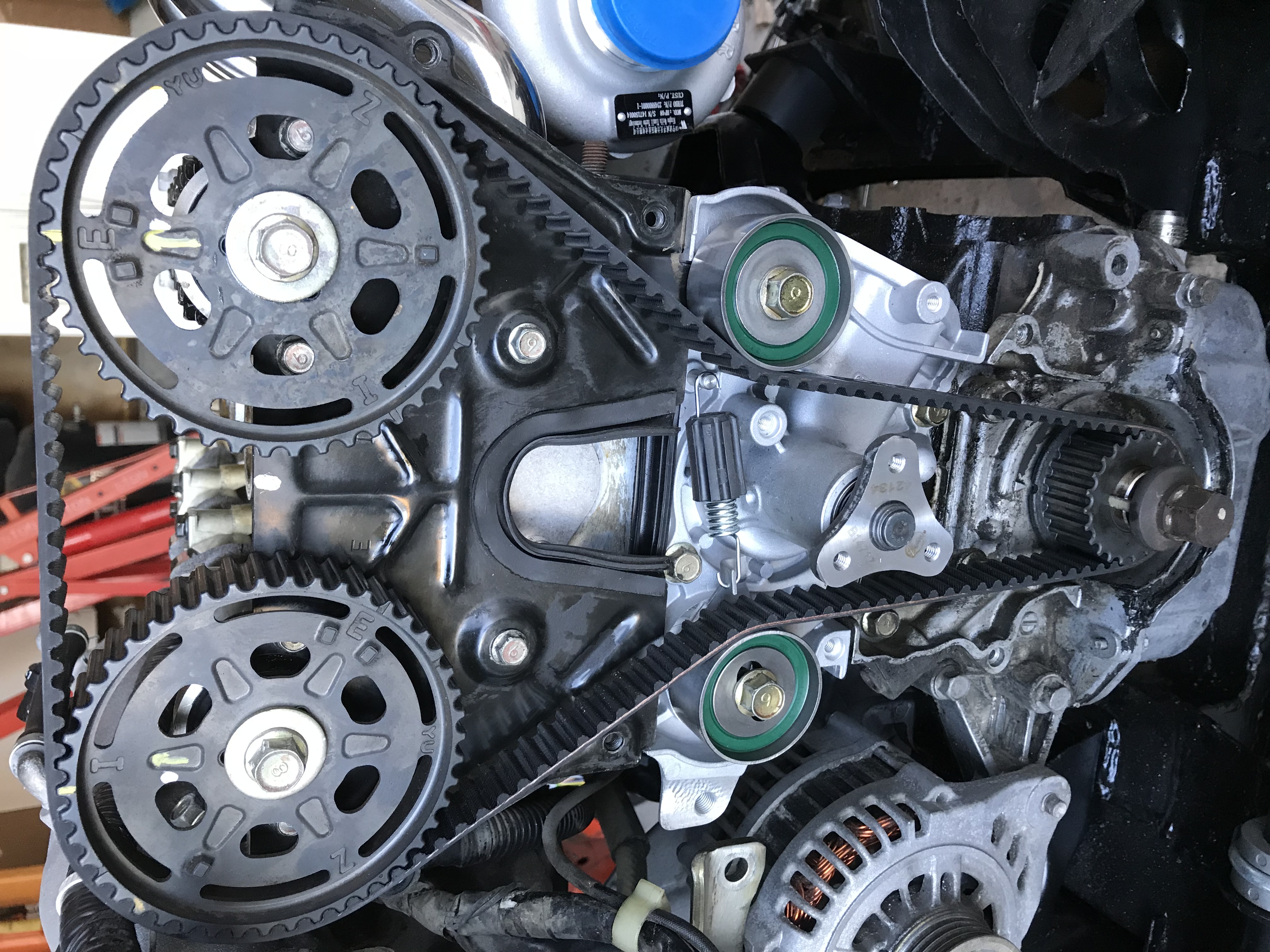

Not to hijack Seth's build, but anything else I need to check before I button this up? I have turned it a few rotations, timing marks seem to be exactly as before, so just confirm the tension is correct and start putting it back together. Any suggestions to set the tension correctly? Have to say this JDM engine was amazingly clean inside, pulled the oil pan and it was clean, no sludge and the cam cover was just as clean.

If the timing marks change after you rotate it, you've got some serious problems

Tensioning procedure: loosen the bolt on the tensioner pulley. Rotate the crank 1 5/6 turns from the current TDC - there's a mark on the oil pump that will line up with the notch in the crank pulley. Tighten the bolt.

If you're doing this with all the front pulleys attached, there's a protrusion on the timing belt cover that lines up with the timing mark on the damper.

mazdeuce - Seth said:

Keith "just pry harder" Tanner had the hot ticket. Once the motor was out and the alternator and AC brackets were off I had plenty of room. Now that I've done it once I'm pretty sure I could modify some pry bars to get one off with the motor still in the car. Not a huge deal for this time as I now need to replace the oil pump anyway becasue of my ham fistedness, but for the future, it's good to know.

So now I need a new oil pump, new pan gasket, New pulleys (is there a version where they are attached to each other?) and a new key, I already have a front main. I should do a rear main and inspect all of the clutch stuff since the car is out?

This made me smile to read. I love it when I'm faced with a situation that has me wondering how I'm going to accomplish it, and someone offers the advice "Try A, B and C". And when I do try it, it works! Such a satisfying experience :-)

Thanks Keith, just watched a video so now I see the mark on the oil pump and understand the process now.

dherr said:

Not to hijack Seth's build, but.......

Please, hijack, ask questions. There's a 99% chance that I don't know the answer and someone else answering it is going to help me out too.

Crank keyway damage in an engine used at high rpm would be a harmonic balance issue.

I would look into aftermarket harmonic balancers and upgraded mounting bolts with a hard setting loctite on the threads. If it was a throwaway engine super shaft lock on the crank nose.

If it can't be fixed with cable ties, araldite and loctite its not an adventure....

The Miata crank nose is a pretty well understood creature. This is not a harmonic balance problem we're looking at. They tend to break the oil pump gears before they damage the crank. This is most likely a loose crank bolt. And it should have been given blue loctite upon installation, but that often gets skipped.

Aftermarket dampers are definitely a good upgrade, but it sounds like that's not the sort of thing this engine is going to get.

Thanks for the reminder, just used blue loctite and torqued to 120 ft/pounds