The engine is finally out of the car. It took a long time not because it's particularly difficult, but because of lots of other demands on my time and 100+ degree temperatures when I had time. I divided the job into parts, doing one section at a time. I generally follow this 'Tech Article' at Pelican Parts: Porsche Boxster Engine Drop / Removal but I modify a few things in the order. Usually I drop the engine and transmission together. For a full car-to-car swap I have dropped the whole rear suspension with axles, wheels, and shocks still connected.

Back of car: Rear spoiler, disconnect engine harness wires in trunk including ground and push grommet to engine side, bumper and exhaust.

Top of engine: Stuff like MAF connector, oil filler tube, brake booster hose, ground and other peripheral wiring, etc...

Front of engine: Access panel, Belt, AC compressor (Make sure it's free from the engine, but leave in place until the engine starts to be lowered).

Sides: Axles nuts (usually), wheels, axle flange bolts on transmission.

Bottom: Coolant hoses, PS hoses, Fuel system hoses, drain oil, shift cables and clutch slave, subframe braces...

Drop the engine: Support with transmission jack/jacks/engine support beam depending on mood, remove transmission mounts, remove front engine mount (4 studs & nuts), lower engine 2", pull AC compressor into the cabin (hoses connected) Look around the engine for what I forgot to disconnect, make sure the hoses will be clear of the E-Brake cables, finish lowering.

Get the engine out from under the car: Most dangerous part - Im working on jack stands, alone, and probably late for dinner or bed. Raise the car as high as possible. Get the engine as low as possible. 6 Ton jack stands at the top peg usually works. Slide or roll the engine out from under the car. The rear studs from the suspension braces are the bottleneck. Go slow or bad things may happen.

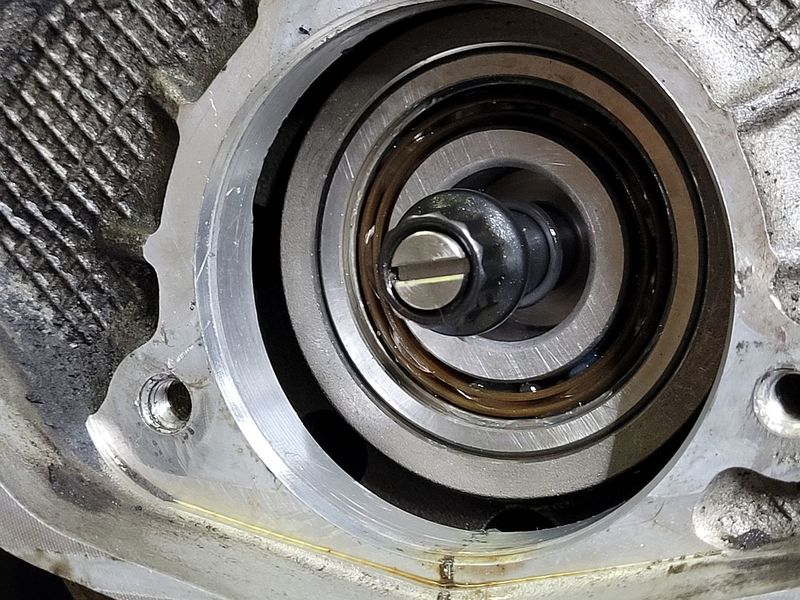

The engine is in the garage and I'm working 7 am to 7 pm until Wednesday. Next task is removing the transmission and installing a LN engineering 'Single Row Pro' bearing using my 'Faultless' IMS tool. After that I will swap on a fuel rail (probably just swap the whole intake system) for the return type fuel system in the car the engine is going into. High temperatures should be in the lower 90s next week and I'm not scheduled to take care of any grandchildren. I may get a lot done.