cmcgregor wrote:

Wow, this has really moved since I checked in last.

I'm also fairly local, though I'm busy this weekend. Definitely interested in checking out the makerspace though, how are you liking it there so far?

I helped start it, so I'm definitely biased. The first Saturday of every month is tool checkout/training day, so don't feel rushed to get in right away. Open house every Monday, and I'm here most nights if you ever just want to drop by.

OK Seth, I spent the night re-mathing and re-bending the driver's apillar. Tomorrow is the passenger, and the weekend is coping and tacking, then adding rockers, windshield, and dash bar. So far, everything is 1.75" DOM.

For my own future reference, this is 20" straight, then a 47 degree bend, followed by 24" straight, 13 degree twist on a 42 degree bend, then 24" straight (which will be trimmed and coped to fit the main hoop). I may add one more slight inward bend to meet up with the main hoop.

I didn't really plan to get anything done today, just clean up the shop a bit in preparation for the weekend. Man, was I wrong. I nailed the passenger side A pillar so nicely, I decided to make another driver's side replacement ... but twisted the wrong way, which resulted in another perfect passenger's side A pillar. Then I made one more driver's side, and went so far as to add a small bend on the back of it to get it to fit up with the main hoop just so.

Tomorrow, I get to break out the welder, tack it together, and start in on reinforcements.

Finally, everything's aligned and tack welded into place. I spent most of the day fine-tuning fitment so it's symmetrical on both sides and so I have as much headroom as possible, but the results are worth it.

All told, I bent 6 'not quite right' A pillars throughout this process, so roughly 40' of material that didn't make it onto the car. It'll all get used, as door bars or similar.

NOHOME

PowerDork

12/4/16 5:55 a.m.

I have learned that coming to grips with "Nope that is scrap" is an important turning point in getting a nice result at the end of the project.

I suspect that a lot of projects die when the number of "Good Enoughs" reach the point where the completed work does not deserve the remaining amount of time and money to complete the car.

Did I read right that you are building the car in one of those Fabrication Collectives that I have read about? I have lobbied the City a couple of time to see if there is a way to get one started here in London, but not finding anyone who sees value.

I work in software development, where the goal is generally to 'fail fast frequently' - Make many iterations, and be able to re-create the entire product quickly and painlessly. That may not necessarily apply to roll cage fabrication, but it seems to be working out so far. I see this as product development, not as a work of art. Once I've nailed down what I want all the measurements to be, I don't have to be scared of building a new chassis/car when I toss this off a cliff.

You're right, I'm building this in a Makerspace (shared non-profit workshop). We didn't get any support from the City of Manchester (NH USA, not UK), but just got ~20 people together who were able to pay rent on the space and started drafting the docs necessary to start a business. Now it's a pretty solid community, and we grow every week.

A full day of work today, and it doesn't look like much progress.

My friends Mike and Matty came out to help, and we wrapped up the rear body jig, then centered and leveled the body on the chassis. The A pillars weren't perfectly symmetrical, so they came out, received appropriate trimming, and went back in. We coped the dash bar, and bent up all the door bars.

With the car on the rear body jig, we pulled the 2x4's that were supporting the middle of the car. A new horizontal support bar was welded in in front of the A pillars, and the existing horizontal support bar was removed. That free'd up enough room to test fit the seat, and it looks fantastic. I couldn't get any photos of it, but there's plenty of room all around in this thing.

Finally, we took some measurements to ensure that everything that's tacked together so far will pass tech without any issues, and pressed on 'till midnight.

Lots of tubing was cut today.

UPDATE!

It's Saturday, so I don't have a 'big' update to announce.

I think I've mentioned it before but in case I hadn't, we're recording a whole web series for this build, similar to what I did for the CRX. I've always enjoyed watching honest, well-produced video over reading build threads, and thought I'd give it a go. As I learned from the CRX build, it really requires a dedicated film crew (of at least 1 person). The level of quality I want really isn't possible if I'm trying to build and film at the same time.

With that goal in mind, I spent the morning laying out the video capture gear and taking an inventory of what we use on a regular basis. This is the result.

Yeah, I agree. This might be a bit silly.

Anyway, with that out of the way Mike and I started off by finishing coping for the dash bar, which looks pretty solid now.

After lunch, Mike took care of the sill bar coping and I took care of the bent door bars. They aren't quite ready to weld in, but we're making good progress.

Unfortunately, we ran out of material for the remaining sill/rocker bar and the windshield bar (both are required to run Mt Washington). I'll have another 24' arriving Monday morning. Tomorrow, I think I want to set our sights on tackling the front suspension jig, since the 'core' of the cage structure is finally coming together.

This is definitely behind the information you folks have been getting (video editing takes a lot longer than writing a post), but I'm still really excited to announce the video series of this build.

Driven Daily Datsun Trailer on YouTube

NOHOME

PowerDork

12/23/16 7:18 p.m.

That video was outstanding quality.  Can I please have another?

Can I please have another?

NOHOME wrote:

That video was outstanding quality.  Can I please have another?

Can I please have another?

Really glad you liked it. I'm playing my hand close till new years, but you can expect more.

I was really surprised and excited to see the notification of a new video! I can't watch it right now but I can't wait to.

More coming soon. I spent the day today getting the new sill bars cut and coped and ready to weld in tomorrow (if I can make shop time around Xmas stuff).

Love the videos! Great progress, I'm excited to see more.

After test fitting the seat, I decided to move the floor up significantly. With my original floor location, a 6'2" person would have to struggle to see over the dashboard. The higher the floor is, the more ground clearance I can add [B]or[/B] the lower I can place the center of gravity. I like both of those things, and I'm only 5'6" so if I'm going to go to any extreme, it'll be the "build for short people" rather than "built for tall people" extreme.

Unfortunately, that was not a trivial change to make. I had to chop out the sill bars and door bars, then I had to cut out the X brace in the main hoop. Having the X brace terminate below the floor would defeat the purpose of moving the floor up, so it HAD to go.

I made new sill bars and X braces, and am just starting to catch back up to where I was a couple weeks ago.

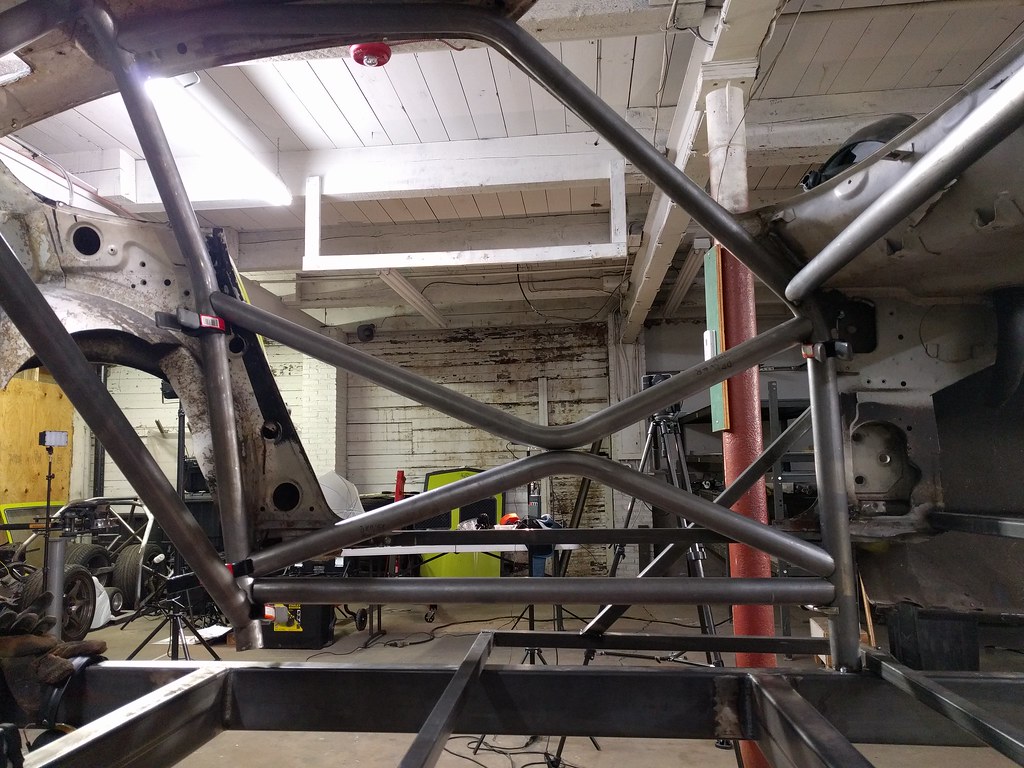

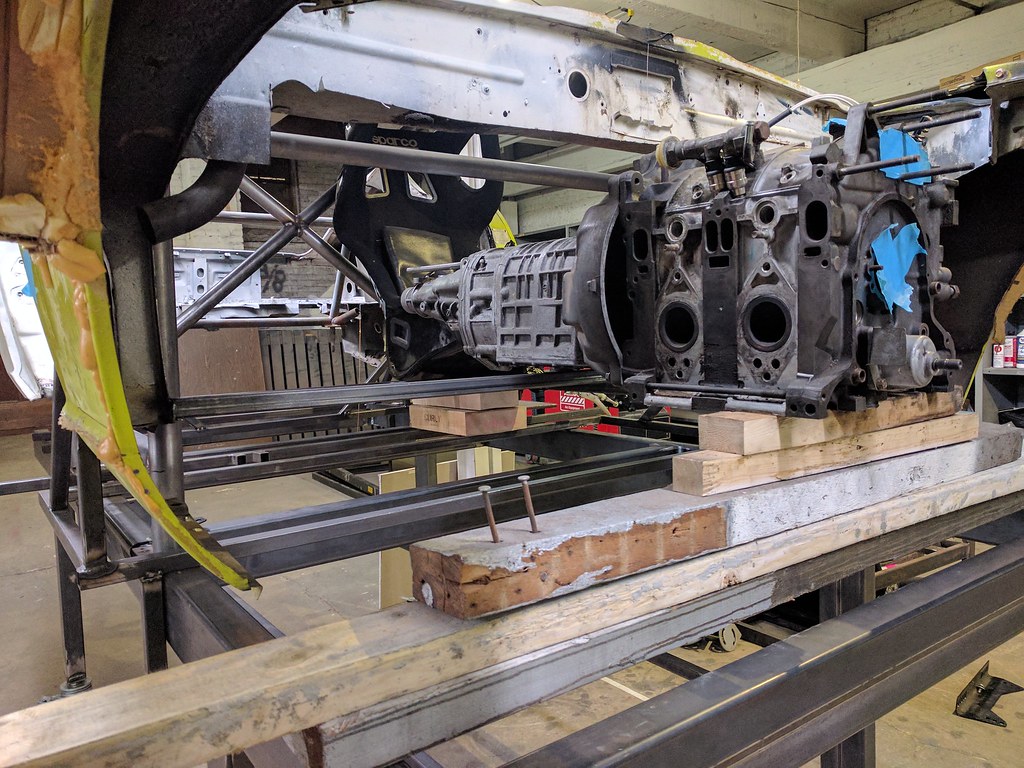

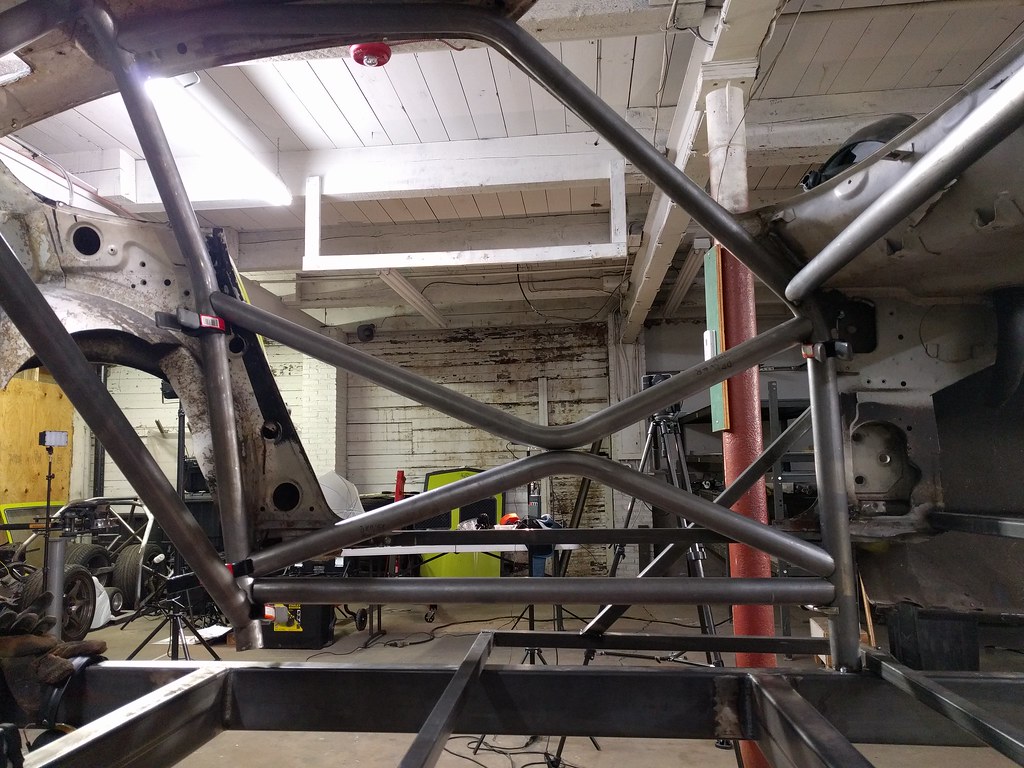

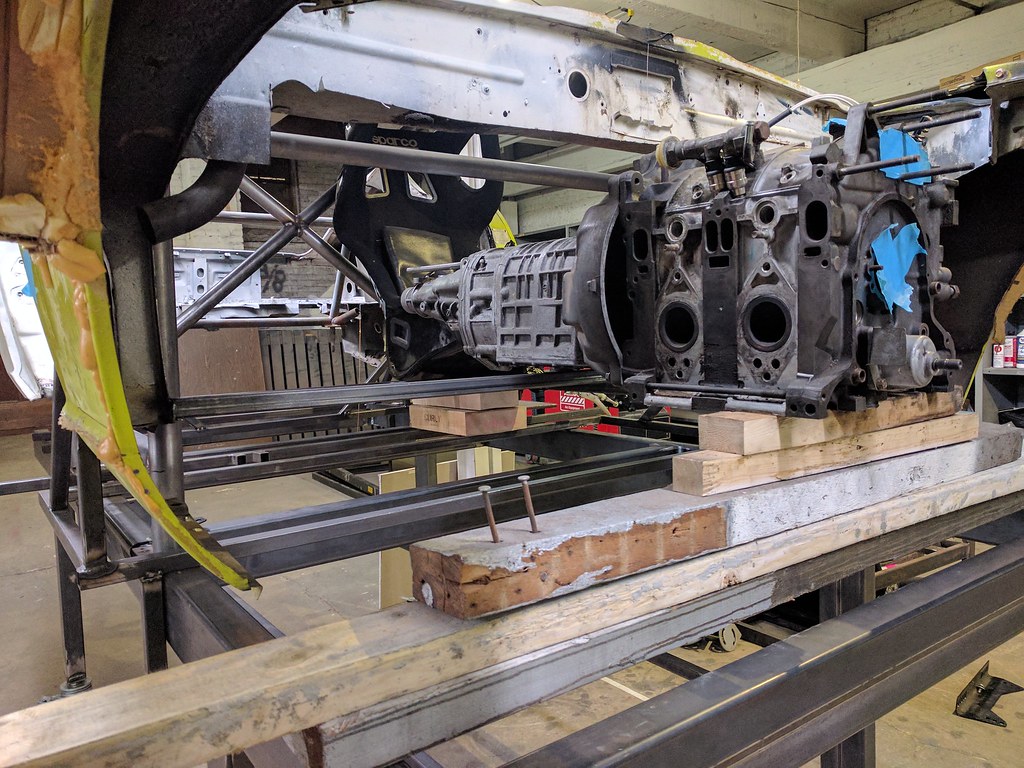

We went from this:

to this:

It looks like such a simple change, but was a pretty massive effort. On the positive side, I'm getting quite good at coping with an angle grinder now!

Door bars look great. How much tubing have you gone through so far?

I've been deliberating similarly about the floors in my wagon, but can't make real decisions until I get it apart

NOHOME

PowerDork

1/1/17 7:15 p.m.

That tube notching looks first class. Any lessons to be passed on?

Crackers wrote:

Door bars look great. How much tubing have you gone through so far?

I've been deliberating similarly about the floors in my wagon, but can't make real decisions until I get it apart

Everything changed when I put the seat in and started placing things in space. Math is great, but nothing beats a good mockup.

I originally ordered 4 20' lengths of 1.75" x .120", then ordered 2 more when I ran out. I have one more tube left over, and several 'failure scraps' that could definitely be repurposed elsewhere on the car.

I'm using 1.75" x .120" for all of the structural elements of the cage required by the rules. It's extreme overkill; I could get away with 1.5" x .095" for a car this light, but the "core" of the cage is so tight-fitting to the squishy human bits inside that it should only deform under extreme circumstances.

What I want to move and absorb energy is everything outside of the main cockpit.

NOHOME said:

That tube notching looks first class. Any lessons to be passed on?

Get a short piece of tubing to test fitment frequently. I've developed a technique of sanding down the "face" of the tube to define what the outside of the tube profile should look like, then cutting away the wall thickness until the inside of the tube matches the outside. I'm working on a short video that explains it in more detail.

Expect to make mistakes. Plan for them. Plan on lots of them.

NOHOME

PowerDork

1/3/17 1:09 p.m.

"Expect to make mistakes. Plan for them. Plan on lots of them."

Got that part well covered! I could make a whole thread on the subject of stuff I had to re-do.

I could make a whole thread on the subject of stuff I had to re-do.

Finally, the video series is ready to go live!

Driven Daily Datsun Week 1

2GRX7

New Reader

1/10/17 11:27 a.m.

Yup! Subscribed! Really good stuff!

One last alignment of all the 'core components' this weekend, then turned tack welds into 'for keeps' welds.

Another video just went live

Driven Daily Datsun Week 02

This one's pretty short. Filming and building the car is pretty expensive, in terms of hours and dollars. Especially in the beginning (before we had a solid process established), that meant that we didn't get a lot of footage for some of these episodes.

Maybe at some point, we'll open up some fund-raising opportunities to help fund the video series again. Would anyone be interested in contributing to something like that?

Driven Daily Week03

The Mt Washington Selection Committee is going through the arduous task of selecting who they accept to race in 2017, and I'm absolutely on the edge of my seat with anticipation. With 99 entries and only ~45 slots, our chances are fair of being selected. If Driven Daily is on the honored list, we have to double down and focus even harder on that deadline. If not, we'll have 3 years to shake the car down before the next event.

Week04's episode is a bit behind schedule, but that's because we've been rushing to get the project caught back up. We just mocked up the cockpit to make sure we have sufficient room for everything with the cage in its current state, and I'm very very happy. The 'foundation' of the cage is complete, and we can move on to more exciting parts of the car.

This weekend: Front suspension (finally!)