Syscrush said:Maybe with sleeves there's less/no risk of the deformation?

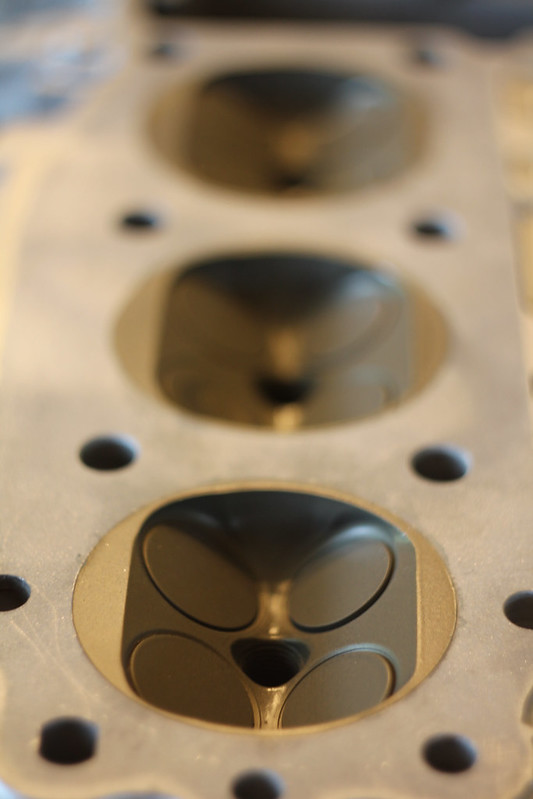

The OEM ferrari setup is pre-finished drop in sleeves. They come round, they are not produced with torque plates or anything similar. I guess way back the goal was track-side rebuild...just a guess though. They make that work by using head studs that are pretty long and are basically screwed into the main bearing webs, below anything that needs to stay round to cylinder wise. Then the cylinder itself floats in the block, clamped only on a flange at the deck and they stay pretty round.

It is no doubt better the finish with torque plates, but the open question is whether is enough better to bother with given they are already much rounder than more common head bolts into the deck designs deliver. I was leaning to at least hone in the block but as that proved problematic the new thought is finish on the bench, then double check in the block and if needed a quick hit with the hone again.

as for material to hone, yes ideally you hone only what's needed for surface finish.....the question is know what that number is. The general rule is plan 4thou but I didn't know what the darton finish would be and they were saying plan 10 to clean up I ordered them at 6 under knowing I didn't want to do any boring. Seeing them honestly 2 or 3 at most is all I needed to hone as the finish they provided was quite good so next time I'll know. and the first 2-3 comes out fast as you're knocking down tool marks but now I'm removing material everywhere so its slower going. My time is free though and I'm saving about $800-$1000 the shop was going to charge to do the work so I can spend that elsewhere.

Last night I had to help with homework but tonight I'll be back in the shop and expect to have them all up to ready to finish hone condition. then 4-8 at that step and its tim to install them....Saturday hopefully.