Hullo everyone!

This is my second build thread, my first being the 2004 Sentra V6 build

This thread is a continuation of this thread, the "What to bring on a 1000 mile road trip" thread

The truck has been sitting just over a year now. I'm taking a step back from autocross this season and have chosen not to insure my '99 Civic autox-mobile. Instead, I'm spending my weekends and money getting the rust fixed up on this truck.

Now that spring is almost here in Winnipeg I'm starting the work on the truck. The plan is to pull the cab, have it sandblasted, order patch panels where I need them, weld them all in, epoxy primer, paint, and re-assemble. I'd like to keep the patina'd look of the truck so just the cab rust is being fixed. The doors and cowl will go back on as-is (they're in good shape actually).

This afternoon I started pulling the front clip off in one piece.

Once the cab is off, I'll put it on a dolly. When it comes back from blasting I'll wheel it into my tiny garage and start cutting and welding.

How did this thing make it 1000 miles again?

Can anyone help identify this Edelbrock carb? It needs a rebuild. I'm much more comfortable around fuel injection....

Worrisome bits

The firewall panel is seperating from the floor panel

Is this an original column? The paint doesn't match

As I left it for the day.

The front clip is ready to come off in one piece. I just need to drain and remove the radiator, disconnect the trans cooler lines, disconnect the a/c lines, and pull the column. As it sits now I can lift each corner up a couple inches.

The carb should have a number stamped on the bottom right front. Model should be the first 4 numbers. At least on my edelbrock.

i bet a quarter it's a 1406.

I got a quarter, but I say 1406 also.

Thanks guys, I'll take a look for that number.

Need to pump the gas for a cold start (hot is fine) and it didn't want to hold an idle last weekend when I moved the cars around. I don't have a tach, but it also sounds like it's running way too fast on cold start, and getting it to kick down to a lower step without going totally off the choke and stalling is difficult. I figure a good cleaning should help.

It's a 1406!

Looks like I need Edelbrock #1477 rebuild kit.

A couple of the guys from work helped me lift the front clip off at lunch.

Next time, I'm removing the front wheels...

And some shots of the damage uncovered. I'm not sure if I should be looking at getting a new firewall or not, the bottom section is pretty gone. They only make non-a/c firewalls too. The goal is to have the rust all repaired by the time snow hits, pretty ambitious for a first timer. So whatever makes for a faster and easier repair will be worth it.

I don't know what's going on here, if that's factory or not. I'll have to try to find pictures from another truck.

that all looks like "make the panel yourself" patching. firewall isnt going to include those bits i do not believe. i think it stops at the pinch weld seam that appears just fine in both of your pictures.

i have a mostly unmolested 68 c20 that i can try to get a couple reference photos off of, that's also going to end up parted out here pretty soon due to rust and bent frame.

How does the inner cowl look? lol

The pinch weld seam isn't in great shape either.

It's that 1" strip between the firewall and inner cowl.

Doesn't look like the replacement panels come with it. What a stupid place to rust!

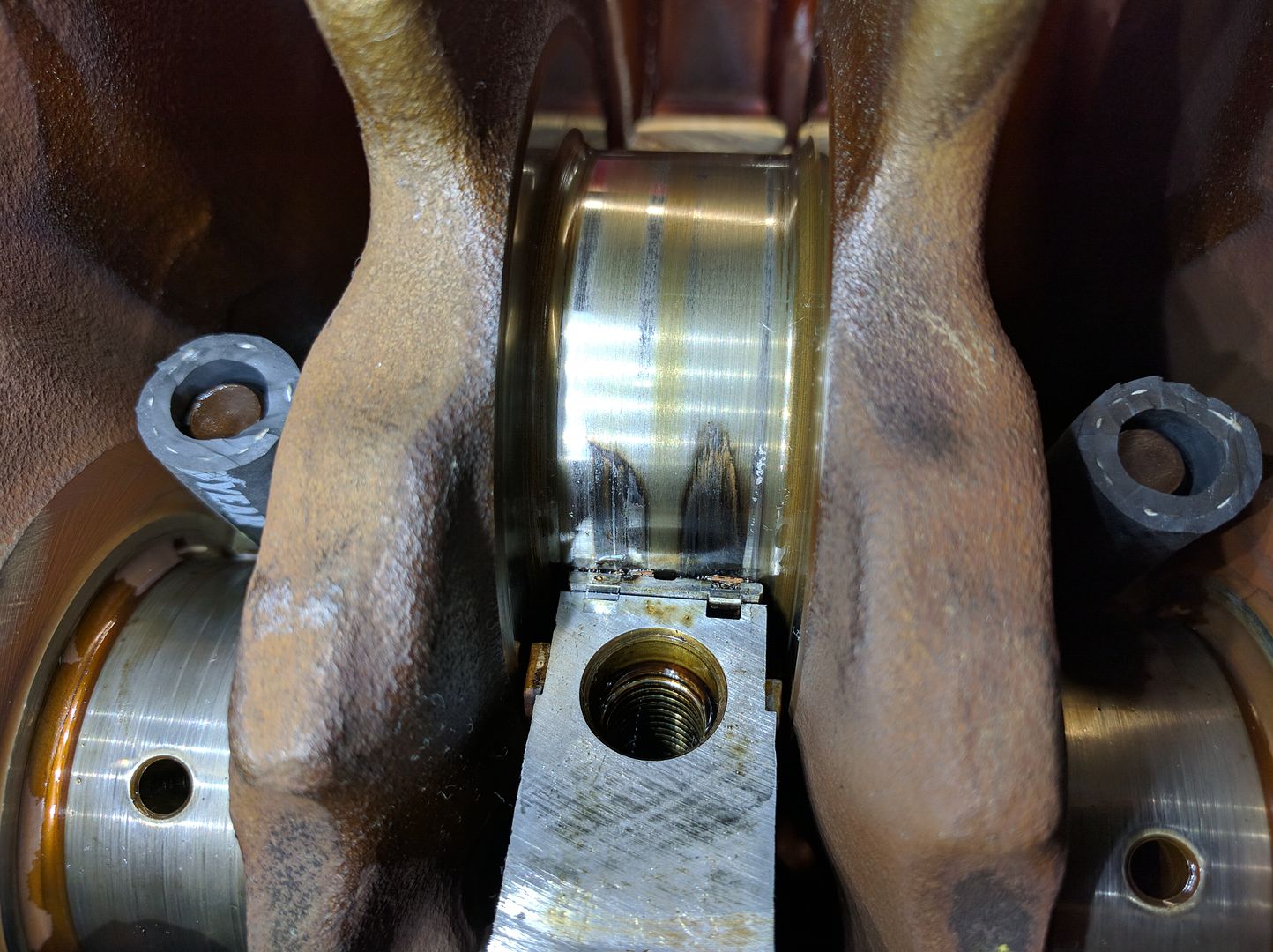

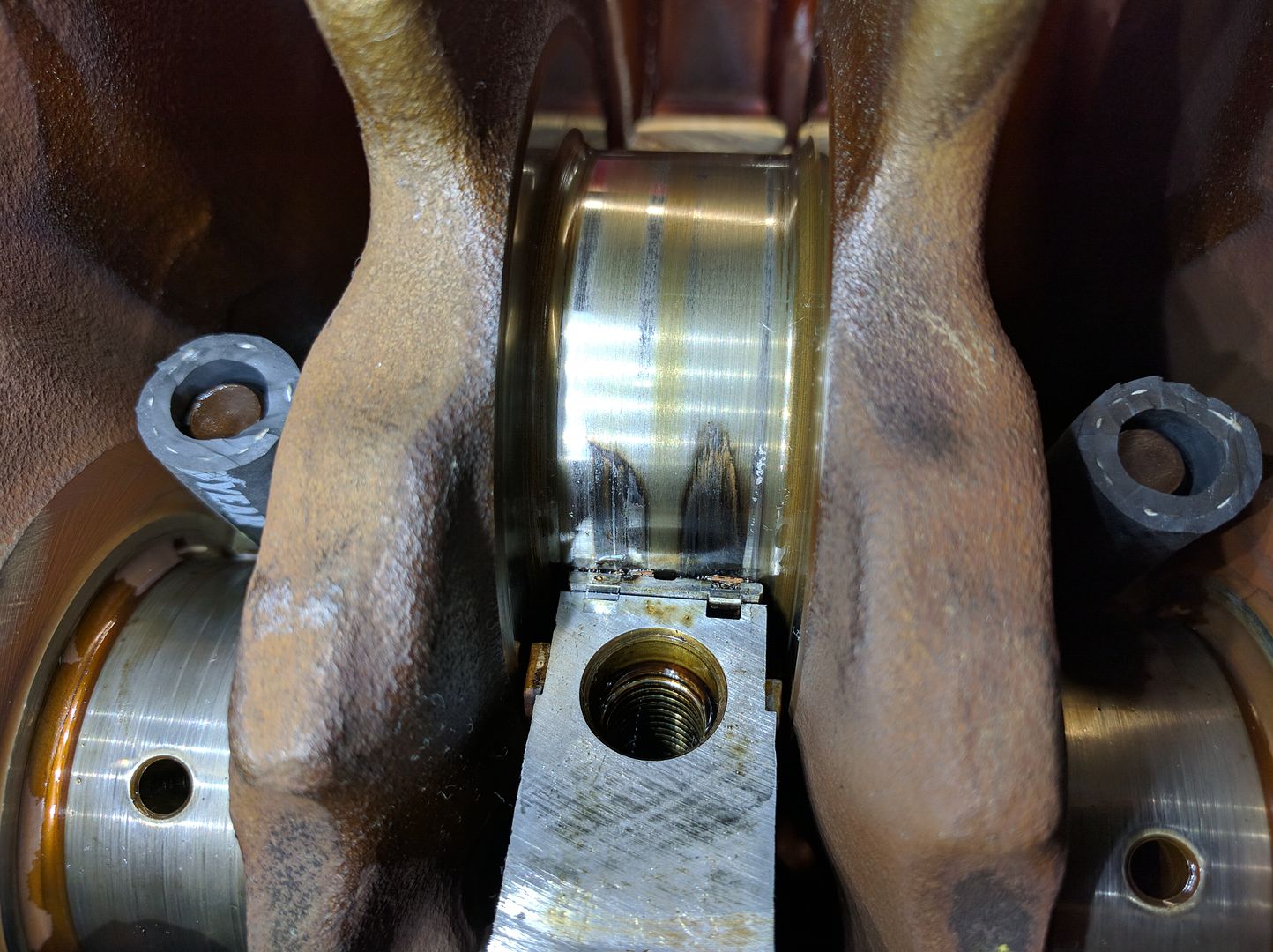

No work done on the truck today, was busy swapping engines on one of my Preludes when I found copper bits in the oil pan of the "good" engine, which lead to this.

It never ends...

Spent the morning at the U pull yard getting Prelude parts, had the afternoon to work on the truck.

Got the dash pad, brake pedal, wiring, ebrake assembly, wiper motor, heater box, ducting, heater controls, glove box, and gauges out. Basically almost completely stripped the cab, with the exception of a few little odds and ends and the gas tank.

I'm going to need a little bit from a doner cab, I don't think I can re-create this. Wiper motor mounting, viewed from below.

Daylight everywhere!

May 6th, Friday evening. My dad came over to give me a hand.

Scribed the door hinge placement, pulled the doors off.

Up and away!

A little later we had a dolly built

Cab sits nicely on it, and there's room for the engine hoist to fit under. I may add some bracing at the bottom for transportation, but the bits that give it height are actually pretty stable.

Saturday the 7th I shuffled cars around

And rolled it into the garage

A tight fit, but it all fits

Next is to pull the glass, and call around for some media blasting quotes. I also want to swap out the two straight wheels on the dolly for another pair of locking swivel casters so it's easier to move around.

Not too much work on this as I've been focusing on cleaning and organizing the garage for the past week or two. I've been treating it as a storage container for the past 3 years basically and just tossing stuff on the shelves and floor, there was no room to work. I'm pretty much done that now, so I've been working on the truck.

My girlfriend gave me a hand and we got the windows out. I also swapped the casters on the dolly so all four are swiveling and locking.

I also started taking the dash out as the A pillar rust extends up under the dash. This is a bit tricky as it's welded in all along the base of the windshield pinch weld.

The last spot weld holding on basically came apart by itself.

Everything out

And the problem areas.

I'm clearly in over my head now.

I'm clearly in over my head now.

It's like the truck is rusting from the inside out at the seams. I really should be looking for a better cab but I'm fairly certain I don't find anything locally and shipping is a gamble. I've put a ad up on kijiji (what we use locally instead of craigslist).

It's only metal right? It's fixable, I'm just not sure I can succesfully do that on my first attempt.

Look for a new cab. If you can find something in southern Washington or Oregon you will spend far less in time and money to drive and get it than you will to fix what you have. I love wrenching but rust makes good people do bad things.

That's sort of the plan. I'm located in Winnipeg, Manitoba, Canada though....that makes everything far. I don't have a truck (other than this one) or trailer either. Shipping would be my only option.

NOHOME

PowerDork

5/28/16 5:37 a.m.

Have you already bought the firewall panels?

If you do media blast, don't let them anywhere near the roof panel or the back of the cab or the doors skins.

Nope, I have not yet purchased anything. I found a semi local cab without a title on a Facebook group last night that appears both worse and better than mine. I'd like to check it out first before buying any panels. The replacement firewalls you can get do not go to the base of the windshield, only to the bottom of the cowl.

My plan for blasting was to take a can of orange spray paint and just go along the seams and problem areas and tell the blasting place to just blast the orange areas.

So I bought that local cab I found on Facebook. It's a '72 with no title, and it's been blasted and epoxy primer'd.

It was delivered Thursday night.

The plan is to use panels from this one to patch my cab. Before anyone gets mad at me for cutting up a good cab, here's some of the bad parts:

The whole passenger rear corner has been poorly grafted from another truck at some point, in addition to a couple cab corner patches.

Holes in the roof skin and windsheild frame.

The floors and rockers have rotted out, patched, rotted again and patched again.

I got the dash out of the parts cab today though. Here's what I'm after:

I have many many many hours of drilling spot welds ahead of me....My poor cordless drill is taking a beating so I picked up my dad's corded drill. Probably won't be many updates until I've got the two cabs all apart.

I'll be measuring everything closely on my cab and likely creating a temporary cage/brace inside mine with bolt-on attachments points at fixed locations such as the brake master holes, the cab mount bolts/studs, etc to keep it square when it's all in peices and to give a reference point for where I'll put the replacement panels as it goes back together. That's the plan anyways....

Yowza! Hard work ahead, but it looks like you have (just) enough to work with. I applaud your plan to brace the cab before doing any cutting-you will be glad later if you do that now. Ask me how I know.

Great project. It will be awesome to watch you bring this beaut back.

That one really rusted in some weird places, especially for a southern truck.

Cool truck! In for updates.

Thanks guys. As far as I can tell, it seems the windshield leaked or the cowl was full of leaves for a long time or something. In some ways I'd be better off buying a northern truck where the rust is all in places patch panels are available.

Today I got the firewall out.

Lots of spot welds all around, then sawsall across the floor. Made sure to leave the firewall as intact as possible in case I re-use it, and only cut the braces that run under the floor, and not the little bits that extend up the firewall.

Inside

Outside

Outside

I also dug out all the bits I need to convert my welder from flux core to MIG. Going to check if the gas solenoid is already installed tomorrow (welder is at work) and get a tank.

Wow, I applaud your gogetumness but I think you would spend a fraction of the time by driving down to California and picking up a rust-free cab or truck.

^well, that's sort of what the whole buying from Arkansas part was about....didn't quite work in my favour

Went to the junkyard yesterday, explored the domestic yard. Never been there, I've always gone to the import side (same junkyard, two lots across the street from each other). Found an early GMC truck. Straight 3 and manual

Not much left of it, but it has an uncut dash.

And all the bits I needed were intact on it. Oh well, I don't see how I would have got it all apart at the yard as power saws are not allowed.

Decent backup plan though.

Decent backup plan though.

Got the cowl off

The little brackets and channels they have underneath aren't very well thought out IMO. Don't drain very well and any larger debris gets trappd. They came off next.

Little bit of a patch will be needed here, it's a nice and easy flat spot though.

Then the inner cowl

Then the scoop things under the kick panel vents.

Then the passenger side wing

And that's where I left it for the night as dinner was ready. Just need to get the drivers side wing off and I'm pretty much done with this cab.

I've switched from drilling a pilot hole and the fancy spot weld bits to just a carbide burr. The drilling takes forever, have limited access to some areas, and I was chewing through bits at a record pace. The grinding bit doesn't leave as nice panels, but it's twice as fast and far cheaper.

I'd be out there now grinding away on it but it's raining pretty hard. Building a brace for my cab is next. I'll recycle a bunch from the parts cab.

I'm clearly in over my head now.

I'm clearly in over my head now.

Outside

Outside

Decent backup plan though.

Decent backup plan though.