(copied from 3 posts on another forum)

I suppose I should maybe add a little bit of a story here aside from a picture, maybe bring everyone up to speed as to how this happened.

My name is Tim and I work 2 jobs. Day time I work at Napa autoparts, at night I wrench as a mechanic at a well regarded speed shop. We work on a variety of things, from basic maintenance items like oil changes to large scale custom work.

One day, a car many of you may only dream of seeing in person came into the shop.

Why yes, that IS a 92 Nissan Skyline GTR. It was brought in by one of our better customers (he has this as well as a 3.8 supercharged swapped Fiero) as he had seized a turbo on it and was upgrading to a larger pair, which in turn leads to...

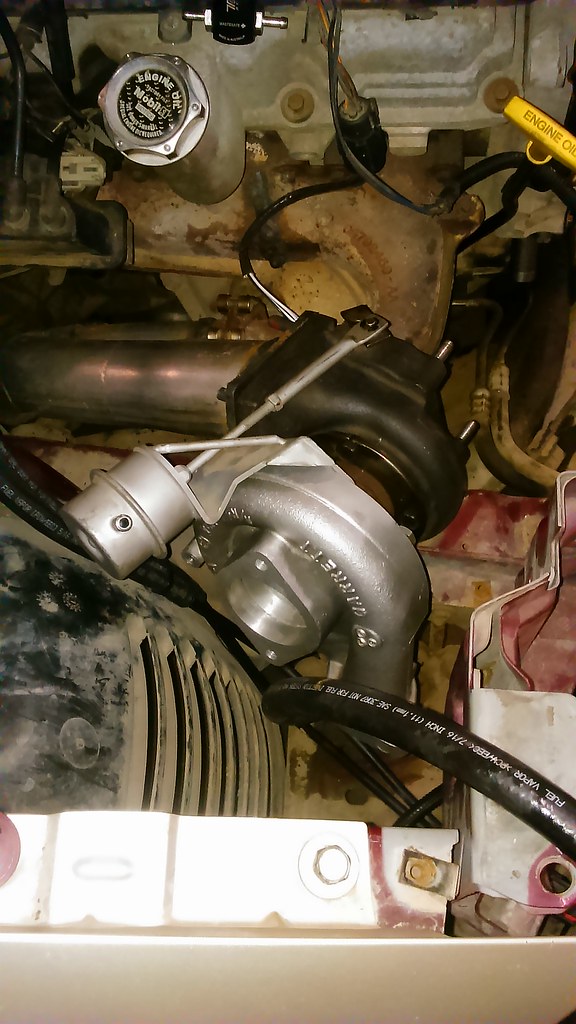

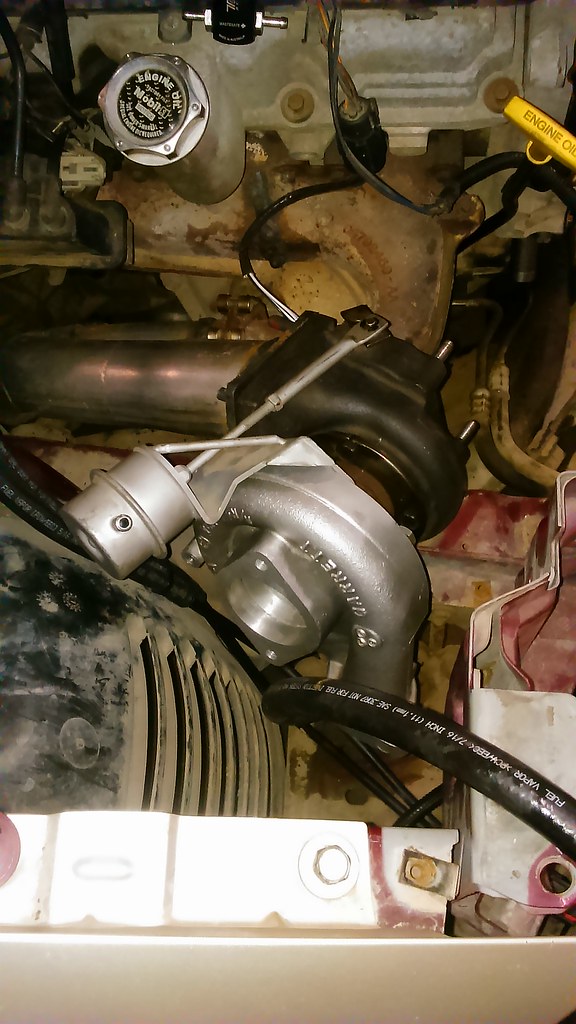

^that^ little guy chilling by the garbage can waiting to be picked up and tossed outside with the rest of the scrap metal. Now being myself and interested in turbo's I had picked it up a couple times and looked it over, probably kicked it too many times to admit while carrying other parts. Well, one day this was chilling by the back wheel of an Intrepid we had in for a blower motor resistor and a battery. Me being a smart ass picked up the turbo and took it to the front (being disassembled to remove the battery) of the car and called my boss over. " Hey Dave, you think this would work on my car" Dave walks over and we look at it, position the turbo a couple times, inspect the turbo, check shaft play, check it over again, position it again and we look at each other and Dave says to me "Probably"

Good enough to me, message the turbo's then owner and we come to an agreement on its value and shortly after I sourced a rebuild kit and new shaft from Australia. So I also got to try my hand at rebuilding a turbo for the first time as well. I will say it wasn't as hard as some thing I have done, everyone should do it once.

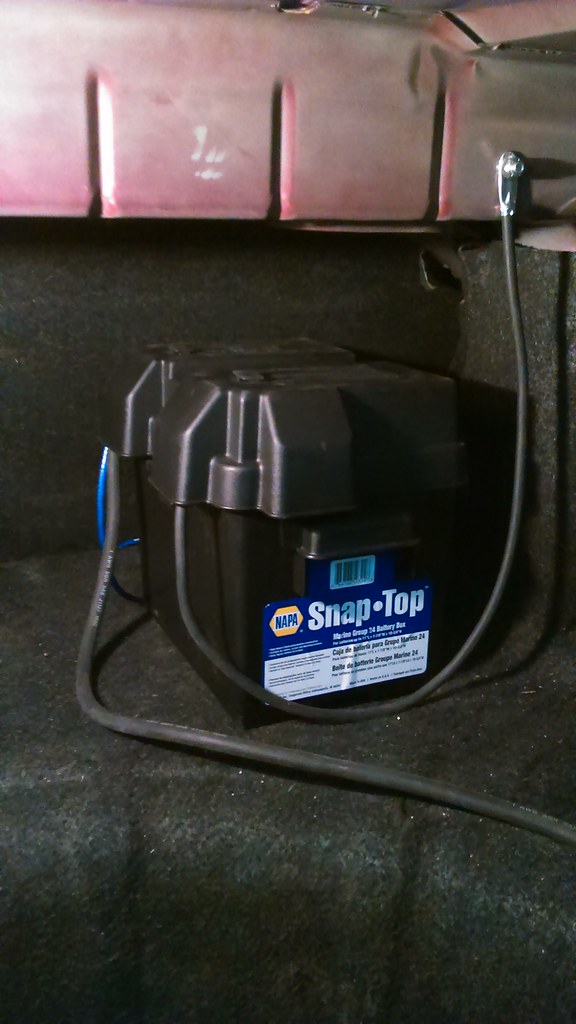

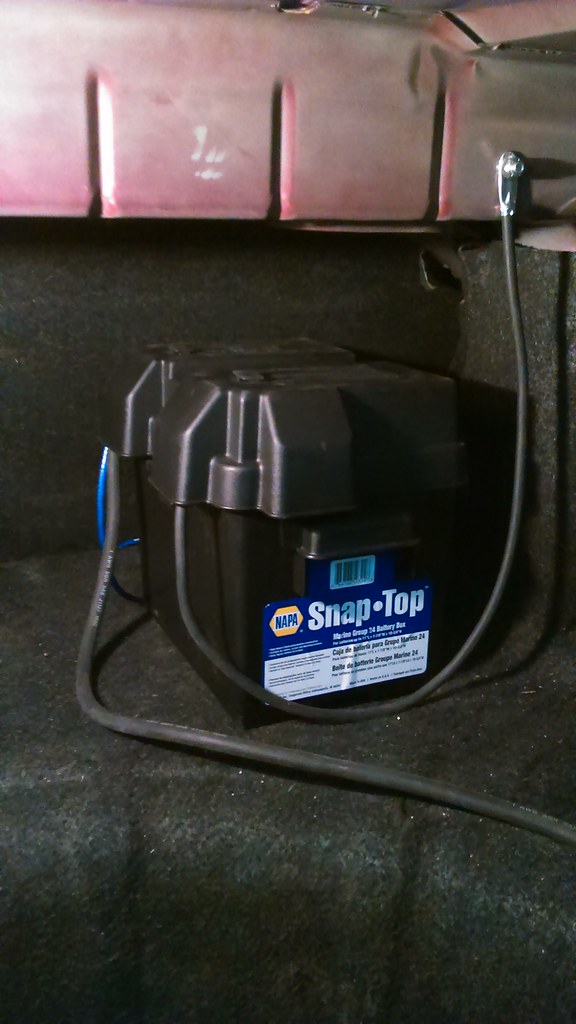

Anyway, as mentioned, we first positioned it on a customer Intrepid with the battery missing, so we decided MY battery had to find a new home. And our trunks are really really big sooo......

we needed to relocate the battery to somewhere else to better utilise that space.

Power cable is 1 gauge wire running from under the hood to the switch, from the switch to the fuse then to the battery.

(Conveniently hidden behind my rear license plate. Remove plate on race weekends and passes tech!!)

(Conveniently hidden behind my rear license plate. Remove plate on race weekends and passes tech!!)

There, looks tidy, and functional. And most importantly frees up loads of space for boost related activities!!

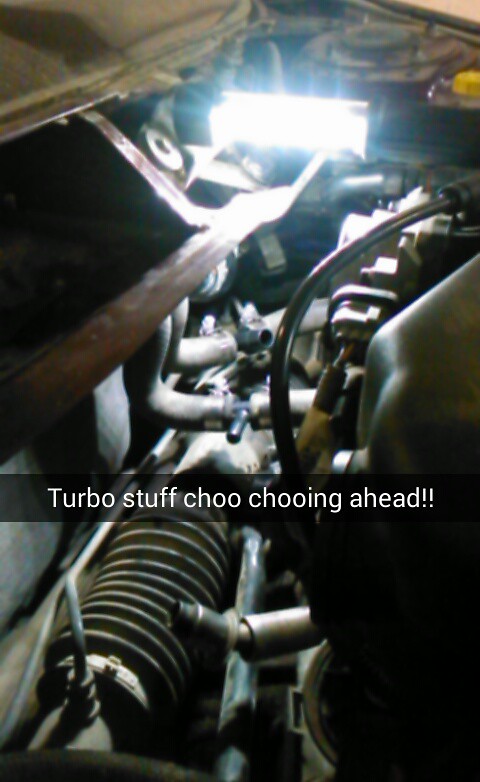

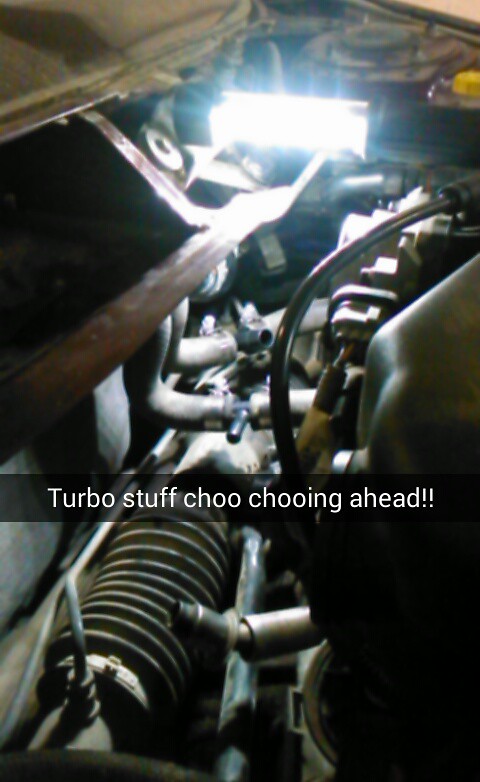

Now with the battery relocated and functioning 100% (Switch kills the car if flipped while running) it was time to get a move on with the forcing of induction. Now as stated before I didn't take many pictures during the build because we were trying to get the car built.

So, while my boss made ripped apart my exhaust to configure out how to make it work....

.... I was over at the work bench rebuilding the turbo!

(this is the internal parts of a turbo, really simple to rebuild, everyone should try it at least once!)

(this is the internal parts of a turbo, really simple to rebuild, everyone should try it at least once!)

(as well as this)

(as well as this)

Then a bunch of loud noises, welding, swearing, and many many many hours were invested and it started to feel hopeless because it is never that easy and EVERYTHING fought us. Hoses, cables, stuff we thought was fine was in the way, we discovered the car would no longer start, we couldn't determine if we could supply the turbo with adequate oil pressure... It was frustrating to say the least.

I spent many nights coming into my car and getting absolutely nowhere. Lots of nights looking at it ripped apart.

Then, finally one Saturday while I am at work, I get a text message from my boss with a horridly compressed video of my car starting and running on 5 cylinders. Timing was out a fraction of a hair, and one of my ignition coils was broken at the connection. The fire was lit, and back at it 110%

Somewhere around this time I had a horrible event happen. I had purchased rear o2 simulators and they were pinned out wrong. First go they popped the fuse for my charging system, and after replacing the alternator, battery testing and checking a crap ton of wiring we discovered it was the simulators. So I found out what the simulators were 'supposed' to go on and repinned them for use on an intrepid and then E36 M3 hit the fan.

Bit of background story time!!

My car started life as a 99 'Base' model. 2.7, non abs, no traction control, no child seat anchors, non skim, hell I bought it with the factory tape deck. Well, I blew up the first 2.7 with a spark plug (young and dumb, its just weird) and replaced it with a second 2.7 from my first parts car. That engine lasted a few years until I spectacularly blew up that engine (2 obliterated connecting rods, third one was bent and cracked) and then I was on the search for another engine and I purchased a 2000 300M. Now over time it was discovered it 'was' a PHP equipped car. I say was because the engine, dash harness and ECM/TCM combo eventually ended up in my car and well, it and my gold parts car looked like this last time I saw them...

I mention all of this because, well...

After changing the wiring on the simulators from what they were 'supposed' to be to what I needed them to be, the first start attempt went backwards and fried my PHP 'Federally Unregulated' (part # 04896-632AB) ECM....

It was not a good day....

So we went searching for an ECM and I got lucky that my first parts car was still in the yard here at the farm so I clearanced the front end to get it out, pulled the skim module and the key and slapped that into the car.

Back on track we finished the installation of the turbo!

We left off with the turbo in the car but that was it, Still need it feeding air into the turbo. And then into the engine.

Add a handy dandy elbow and a K&N filter for an SRT 4 and we have our intake.

Off the turbo was a little bit of a hassle. We have the turbo positioned in a way so that when we add the intercooler, it will be a straight forward installation. Then the piping with run down, then forward, turn into the intercooler, exit and run under the intercooler coming back, turn and run behind the the 'to intercooler' then up and to the throttle body. Problem being for now we wanted a low cost intake since it was going to change and we were 'trying' to make this budget friendly (!!SPOILER ALERT!! Its really not budget friendly, at all) so we utilised the old K&N intake intake tube I have had on my car since the first 2.7. Just needed a bit of a trim and voila, we had a charge pipe!

Now it was around this time that we started to be able to drive the car, running on a 2.7 ecm and driving it but having a serious boost issue. as in 10psi plus before 3000rpm issue. The car would throttle stall really badly and was impossible to drive and we thought it was a fuelling issue, not enough fuel so the car would stall out so we did what any sensible person would do and...

Dropped the fuel tank to make some changes of course!

Here is the factory fuel system. Very basic but exactly what is needed for OEM

And here is what we did! Parts you cant see are a mildly modified assembly with a larger capacity pump (255lph warlboro)

Hanging off the side now is a boost referencing fuel pressure regulator with a 1:1 rise ratio. Presently set on the high end of OEM spec (62psi, OEM is 58 +- 5) And 'should' begin to rise when we start to push for double digits with boost.

The downside is with this, after purchasing the parts and doing the work, it was discovered the boost regulator was actually the culprit of the too high of boost, which has since been removed and we now run wastegate pressure, so this is basically a fancier, noisier OEM setup in the tank.

After that ordeal we had an issue with the charge pipe blowing off when throttle was released. Every Time. We changed clamps, angles, made adjustments and finally added a blow off valve as well as had a small hydraulic line made up to replace what we 'thought' was a leaking hard line (turn out, tiny pin hole in the dipstick tube, who knew?)

And just a little BOV :D

This brings us mostly up to date. I did manage to take the car out in July for some racing and it performed horribly, tech savvy people may spot why when examining the fuel tables...

Suffice to say, that is one VERY unhappy 2.7 ecm

I was able to allocate a 3.2 ECM from a friend who is selling me a pair of parts cars that will be donor blocks for a 4.0L stroker that we are currently piecing together :wink:

So I swapped that over and drove for a bit, developed a boost leak at the elbow at the throttle body, and fixed that with an elbow from a 2.7 which isn't quite 100% fix. Got it to hold long enough to drive around but still had to have the wastegate open a bit as it would still pop off at times while driving.

After burning myself on underhood things when opening the hood after the car had been running I decided to grab the death wheel

This was free and unlike turbo blankets as it had been suggested to me, this allows the entire unit to cool down efficiently were as a blanket will keep the heat contained to one area and cause coking on the internal bearings and reducing the turbo's life span. This hood is in really rough shape. The entire under hood seam is actually rusting and this needs to be replaced. We will be doing this on the next hood as well, but we will be making it a lot cleaner and more flowing with other ideas we have.

Most recently, as in this week, we made a new intake, again, I don't really take pictures while doing a lot of the work so I only have the after pics.

And that ladies and gentlemen is were I am at. Car is driven daily, I am seeing roughly 6psi and there is a catch can installed and we have 3 check-valves bleeding off some boost prior to the remote mounted MAP sensor. We have ordered a small piece to see if we can make a driveability change. Still have issues but we are working them out.

In closing, this was NOT a cheap endeavor. I stopped counting investment AFTER I hit 60 hours of labour! And still working out the kinks to make it effective. Next plan is a complete stand alone as soon as I can afford it and then I will be able to chase down targets, right now I want to find the exact amount of pressure an OEM ecm can handle. it seems okay at 6psi at WOT with a closed wastegate, but has hiccups under mild acceleration.

Any questions? I am willing to answer as best as I can!

Thank you for looking!

TL:DR summary,

Put a turbo on a car that didn't need a turbo.

Needs more track time, but working out the kinks

(Conveniently hidden behind my rear license plate. Remove plate on race weekends and passes tech!!)

(Conveniently hidden behind my rear license plate. Remove plate on race weekends and passes tech!!)

(this is the internal parts of a turbo, really simple to rebuild, everyone should try it at least once!)

(this is the internal parts of a turbo, really simple to rebuild, everyone should try it at least once!) (as well as this)

(as well as this)