Before I go any further, I’d like to take a shot at discussing some of the theories for the failure of the IMS bearing, and the various replacement options. And we are just dealing with “theories” here. Porsche battled a class-action lawsuit on the bearing failure, and the folks in Zuffenhausen have never released a long-term fix. That has left the aftermarket groping in the dark for a way out of this mess; causing loads of virulent debate on the interwebs.

As a bit of background, I’m a maintenance engineer by trade, mostly working on large pumps and small turbines. I’ve done a few root cause evaluations on bearing failures. Understand that I’m COMPLETELY incompetent to recommend a best “fix” for the bearing issue. I’m late to this party, have zero empirical data on the failure, and my understanding of engine internal conditions comes from hearsay and conjecture. If you’re interested, I’ve waded through hundreds of pages of internet discussion, applied my “sniff test”, and I have a few insights. If not, just scroll down a few paragraphs and watch me mangle more engine components.

This is an intermediate shaft. The left end of the shaft is supported by an engine-oil lubricated bearing with a failure rate of zero. The right end of the shaft is supported by a sealed bearing with a failure rate that causes Porsche 986 and 996 owners to develop drinking problems. The shaft sits near the bottom of the engine case and is submerged in engine oil when the car is shut down or idling. When the car is at speed, the sump level drops and the shaft rotates in an oil mist/splash lubrication environment.

The IMS shaft is hollow to reduce rotational mass. As you can see from this picture, the left side of the shaft is sealed with an endcap. This endcap is inserted through the engine-lubricated bearing and contains a hex-head socket for the oil pump drive. On the other end, the shaft is open, and has just received my shiny new bearing.

Now here’s the deal: because the IMS shaft is hollow, when the car is warms to operating temperature, the air inside the shaft expands and a small amount leaks out through the minuscule gaps around the bearing. When the car is shut down, the shaft sits submerged in the engine sump oil and cools; forming a slight vacuum inside the shaft. Nature (and my daughter, by the looks of her room) abhors a vacuum, so a tiny volume of oil is pulled into the shaft through the gaps around the bearing. Over lots of starts and stops, oil begins to accumulate within the shaft. Conditions inside the shaft are not kind to lubricants. The spinning shaft repeatedly shears and aerates the oil, and volatile components boil off and leak away. As the remaining fluid concentrates, all additives and buffers are depleted and the oil turns into an acidic hellbroth.

Failure contributing cause #1 is that the factory IMS bearing sits submerged in this nasty oil. My experience is typical to what other internet mechanics reported - about two cups of this smelly, evil stuff spilled out of the shaft when the bearing came out. This oil seeps through the bearing seal, washes out the grease installed at the factory, and attacks the internals.

However, I’ve seen bearings operate reliably in worse environments, which brings us to contributing cause #2 – loading on the bearing. Spinning the camshafts requires a certain amount of force. There are five chains in the timing system, so there’s a lot of efficiency loss due to friction. So, the shaft sees some fairly high loads during operation. If the timing between the cams in each head and crankshaft isn’t perfect (camshaft deviation) the cam chains can exert a back-and-forth tugging on the shaft (and supporting bearings) that also increases loading on the bearing.

There are other failure modes, but that’s a simplified view of the two that drive the various “fixes” offered in the aftermarket. On one hand we have folks who believe that lubrication is the issue. They advocate providing a direct oil feed to the bearing, or at the very least, installing a bearing without seals which would receive lubrication from the splash/oil mist environment in the engine sump. An open bearing design also provides a drain path for any oil trapped inside the shaft. The source for the external oil feed is a matter of fierce debate. The lubrication system on the M96 engine is not considered a strong point, with lots of small orifices and tortuous passageways. Robbing oil from the wrong area might make main and cam bearings go bye-bye.

There’s another camp that believes that bearing loads are the issue. They advocate a bearing manufactured from exotic materials to better accommodate high loading. Or replace the factory ball bearing design with a roller bearing designed for higher radial loads. Whatever the bearing type, make sure it isn’t sealed so it can receive lubrication from the sump environment.

What’s the best answer? Probably the one that addresses both failure modes – an external oil feed sourced from somewhere innocuous (like the oil filter), combined with a bad-ass aerospace bearing. Of course, that’s also going to be the most expensive fix.

As a Frugal Mechanic, I really wanted the exotic bearing, because, you know, engineering and stuff. However, there were cost considerations when I started this job, and a desire to keep some money in the kitty to cover issues found during disassembly. With 100,000 miles on the car, it was probable that the dual-mass “clutch” flywheel would require replacement, to the tune of $600. $700 CV joints are also mentioned frequently in the bearing replacement threads. As a result, I compromised; selecting a moderately priced IMS bearing “fix” which appears to address both contributing causes. I’ve addressed the loading issue by installing high quality roller bearing, sans seals.

My bearing “fix” has a unique design to address the lubrication issue. Remember the end of the IMS shaft – the one with the sealed endcap and socket for the oil pump drive? Well, the metal wall between the oil pump shaft socket and the hollow interior of the shaft is thin – about .024 mm thin. So, if you poke a small hole through this metal wall, and install an oil pump drive shaft with a machined groove in it, you can meter a small flow of oil from the oil pump back into the rotating shaft. This oil makes its way through the shaft, into the internals of the roller bearing, and back into the sump. Simple, right? So why aren’t all the cool kids doing it? Well, it involves hammering a punch into a highly engineered IMS shaft, which is an $1800 factory part. And it uses a bearing of a completely different design than Porsche installed at the factory. It’s easy to see why this fix may be a little controversial. But it “makes sense to an engineer” – famous last words akin to “hold my beer, and watch this”.

Crawling back under the car, I removed the engine motor mount. This requires jacking the engine up and down to coax out the four restraining bolts and finessing the mount through the subframe. Now we have access to the oil pump casing on the front of the engine:

I removed the cover bolts and used a handy pry point to pop the pump cover off:

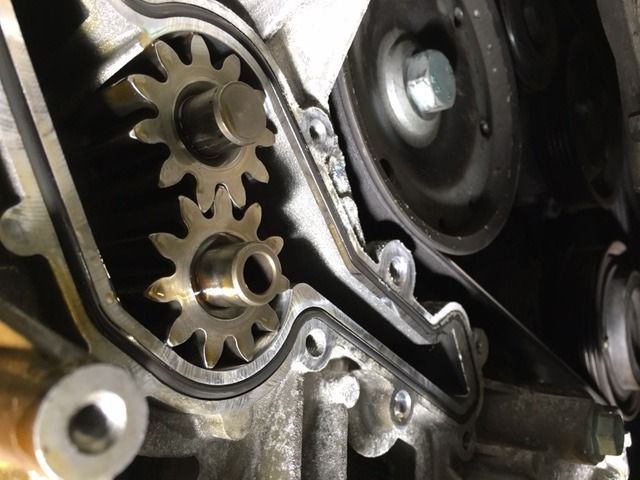

The machined recess for the pump vaguely resembles an erect human appendage. Oh, those wacky Germans! Or maybe I’ve been out in the garage too long. Anyway, the gear with the solid shaft is the one driven by the IMS shaft. Removing it exposes the key:

Which pulls right out and will be replaced by the new one with the machined slot. The kit for my bearing included a needle-tipped punch which was inserted into position against the IMS shaft wall.

My instructions called for punching a hole, 1-3 mm in diameter. I scrounged around in my “box ‘o wire” and found some strands with diameters of 1, 2 and 3 mm to serve as go-no go gauges. Had to hammer a little harder than I expected to pierce the wall of the shaft, but once opened, I was able to expand it to a 2 mm diameter in a controlled fashion. Grooved hex drive key installed, oil pump cover back on, and motor mount back on. Easy-peasy.

Back to the rear of the engine, it’s time to start reassembly. The bolts for the IMS cover received a squirt of Curel sealant to keep them from leaking oil and a dab of locktite to keep them in place.

Observant readers had noted my IMS shaft had shifted slightly when I pulled the cover to remove the bearing. It took a bit of prying to re-center everything when I installed the new cover, but it finally slipped into place. Fortunately, my exertions didn’t change the timing a bit, because my locking tools kept the crankshaft and camshaft sprockets in place. I reinstalled and torqued the two tensioners, removed the lock tools and used a breaker bar to turn the crankshaft through a couple of rotations while carefully monitoring for valve to piston contact. The crankshaft timing mark and camshaft slot realigned to their correct positions, so I popped in a new plastic camshaft plug and re-installed the hatch and carpet cover.

It’s time to address that leaking rear main seal. Drilled a small hole in the old seal, inserted a sheet metal screw and tugged on it a bit. Finally broke the old sealant bond and it came right out. RMS leaks have been a huge warranty repair issue for Porsche, and the seal design has been through multiple iterations to prevent the problem. Installation can be tricky, with many internet mechanics finally purchasing the $150 specialty tool to get the danged seal in. I used an option more in line with the Frugal Mechanic ethos:

A 4” PVC shower drain. Using my trusty Dremel motor tool, I hacked away the internal structure of the shower drain until I had four protruding tabs. When the tool is positioned on the seal, and four flywheel bolts are threaded into the crankshaft flange, the shoulders of the bolts engage the tabs and draw the tool (and seal) into the engine casing. The new style RMS from Porsche requires the seal face to stay perfectly square to the engine casing during installation and finally recessed 3 mm into the casing to prevent blow-out. Blow-out sounded bad, so I tightened the bolts slowly, using a small ruler to measure the position of the seal every few turns. A few times, the seal cocked slightly when I tightened a little too much on one side. However, loosening those bolts and tightening the opposite side served to work the seal back into alignment. It took about 45 minutes, but the new seal finally settled into position.

Sorry for being so long-winded. I’ll get into flywheel, clutch and transmission re-installation in my next post.

The machined recess for the pump vaguely resembles an erect human appendage. Oh, those wacky Germans!

The machined recess for the pump vaguely resembles an erect human appendage. Oh, those wacky Germans!