Ian F

UltimaDork

10/29/13 12:01 p.m.

If you decide to go with a full frame and floor pan replacement similar to the car in the video, I could definitely make use of the OE frame rails and floors (as all of that in my car is rusted bad). In theory, you should be able to drill out the spot-welds that attach the jack struts and floor pan to the inner sill panel without messing them up.

NOHOME

Dork

10/29/13 2:48 p.m.

Ian F wrote:

If you decide to go with a full frame and floor pan replacement similar to the car in the video, I could definitely make use of the OE frame rails and floors (as all of that in my car is rusted bad). In theory, you should be able to drill out the spot-welds that attach the jack struts and floor pan to the inner sill panel without messing them up.

Ian, no need to tell me about spot weld removal. Doing rustoration on Brit cars has been my hobby for a while now. I have nightmares about spotwelds!

The question is how badly I want to preserve them versus just cutting them out and cleaning up with a grinder...want to drop by with a case of beer and a half dozen new drill bits? You can have them at that point.

I've been noticing that the tin on these Volvos is not trivial stuff. Maybe bring a dozen drill bits and two cases of beer!

Ian F

UltimaDork

10/29/13 6:26 p.m.

In reply to NOHOME:

Believe me, if you were not 8 1/2 hours away, I'd be more than happy to drill them out for you. But if means getting some OE sheet metal and subframes, I'd be willing to buy and ship some Eastwood spot-weld bits to you towards the cause.

NOHOME

Dork

10/29/13 7:51 p.m.

Ian F wrote:

In reply to NOHOME:

Believe me, if you were not 8 1/2 hours away, I'd be more than happy to drill them out for you. But if means getting some OE sheet metal and subframes, I'd be willing to buy and ship some Eastwood spot-weld bits to you towards the cause.

How the hell would you ship something like this?

NOHOME

Dork

10/30/13 6:30 a.m.

These look like they might fit the bill. I like the 42 mm offset since I would rather space out to fill fenders or miss chassis than flare fenders.

These look like they might fit the bill. I like the 42 mm offset since I would rather space out to fill fenders or miss chassis than flare fenders.

Ian F

UltimaDork

10/30/13 7:00 a.m.

NOHOME wrote:

Ian F wrote:

In reply to NOHOME:

Believe me, if you were not 8 1/2 hours away, I'd be more than happy to drill them out for you. But if means getting some OE sheet metal and subframes, I'd be willing to buy and ship some Eastwood spot-weld bits to you towards the cause.

How the hell would you ship something like this?

The bits or the sheet metal? The bits I figure I could mail to you through normal post. The sheet metal I was assuming I'd drive up to your place and pick it up. At worst, I may have to cut it in half to fit in my wagon, but the tunnel in my car is solid. It's the just the seat pans and frame rails that are rotted.

Heck... I have some vacation time I need to burn before the end of the year...

The wheels should look nice. It's kinda funny... I've been pondering a 5x108 to 5x100 adapter that would allow me to run my BBS RXII's (VW MK IV Jetta Wolfsburg Edition OE wheels) on my ES. The adapters would bring the offset out to about the same as the stock Volvo wheels (which are in the +20 range).

NOHOME

Dork

10/30/13 7:09 a.m.

Ian:

No need to be in a rush. I can store the parts if need be. I should also look at the parts car to see what is good...since I have no intention of using much of the body, I never spent any time crawling around it.

The other option is to call the guy I got this car from, he has a wagon in the barn with brand new sheetmetal from the firewall forward. He also has loose quarter panels plus god knows what else.

Ian F

UltimaDork

10/30/13 7:19 a.m.

Ah... cool. I should definitely call him. The front head light and front signal areas of my car are a poorly formed mix of rust and copious amounts of Bondo... I need the rear low hatch lip as well as it's pretty much gone across the bottom

When I call this project "one wheel in the crusher" I'm not joking... no sane person would try to save it. But I've formed an illogical attachment to the car... and I suppose that's the root of my "All 1800ES cars should be saved" mindset.

NOHOME

Dork

10/31/13 3:00 p.m.

Ian:

Red one is $3000 described as a parts car.

Blue one is the one I told you about in Milton:

nBSSGy!18U!~~48_20.JPG)

Both look reasonable to me. I have looked at the blue one and it needs some devastating and maybe a new windshield, but I believe it was included at the $5500 he was asking.

NOHOME wrote:

Ian:

Red one is $3000 described as a parts car.

Hardly looks like a parts car and I want those wheels. Just missed a set of those wheels that sold on eBay for $350

Ian F

UltimaDork

10/31/13 3:45 p.m.

In reply to Sine_Qua_Non:

No kidding. Gah!!

Sine_Qua_Non wrote:

NOHOME wrote:

Ian:

Red one is $3000 described as a parts car.

Hardly looks like a parts car and I want those wheels. Just missed a set of those wheels that sold on eBay for $350

Underside rot? Pretty common for the car.

Ian F

UltimaDork

10/31/13 9:39 p.m.

In reply to Harvey:

True... I know that rot well...

NOHOME

Dork

10/31/13 9:46 p.m.

NOHOME wrote:

Ian:

Both look reasonable to me. I have looked at the blue one and it needs some devastating....

Got to start proofreading what the spellchecker fixes...Make that "Detailing"

NOHOME

Dork

11/10/13 5:29 p.m.

![]()

good day in the shop today. Had some good friends from the LBC community come by toinform me that I am insane.

good day in the shop today. Had some good friends from the LBC community come by toinform me that I am insane.

An engine and transmission arrived an is available for measurments. Looks like it should fit in the hole.

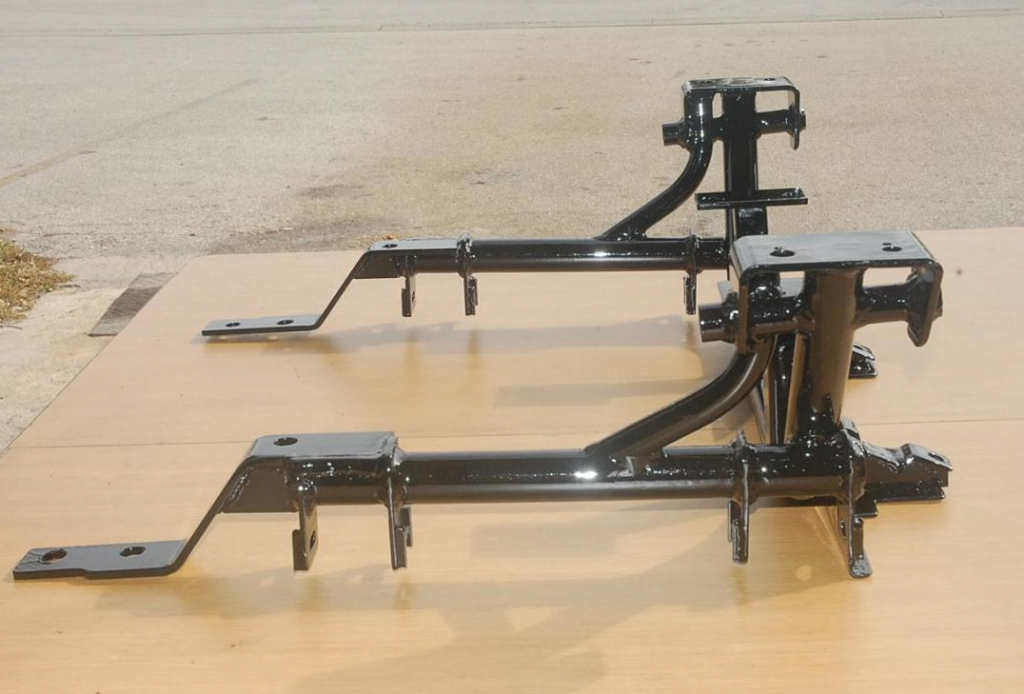

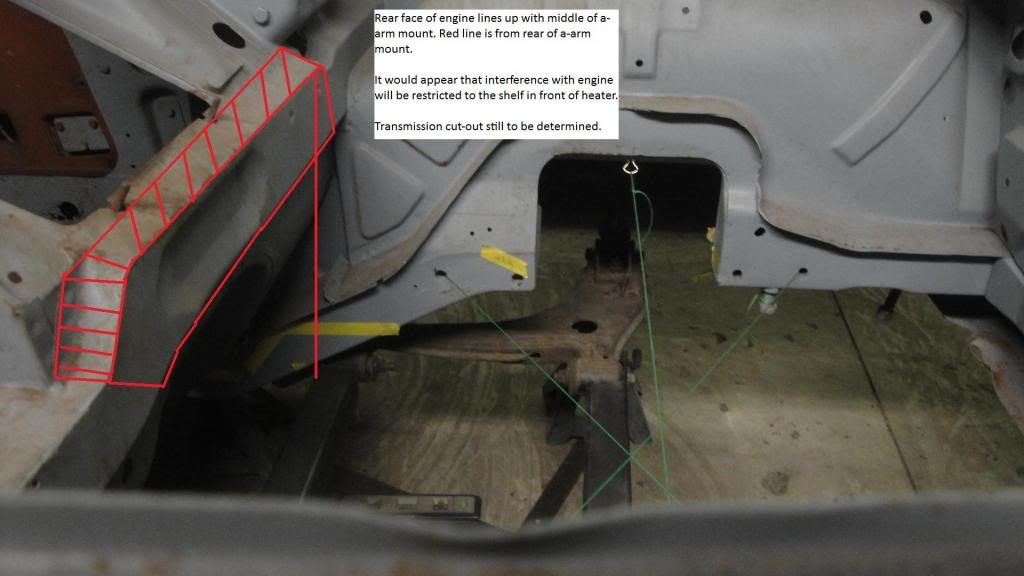

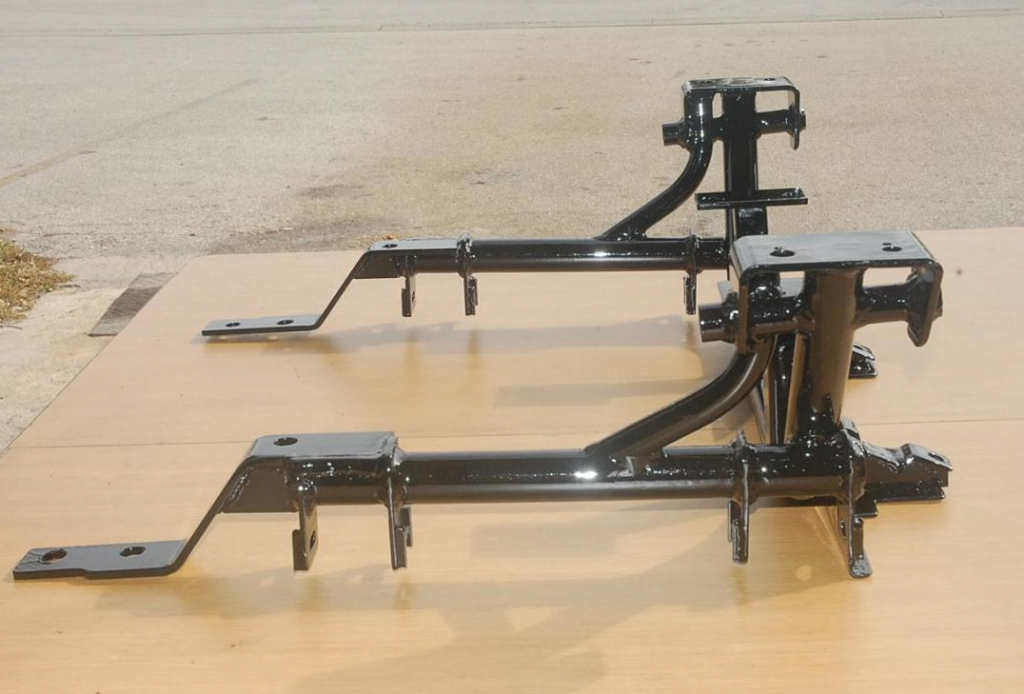

The best news is that I think I can built the suspension off the existing frame rails. I thought I would need to build new frame rails inside of the existing ones, ( and have to chop out the originals) but if I turn the pickup-points so they face "down" rather than sideways, I end up in the middle of the existing frame span. That is good. See image of the Miata conversion frame for an illustration of what I am thinking. The wider space between the framerails also gives a lot of room on the sides for manifolds.

Today's effort was to make a jig to see if I can get my ride height with the rear mounting point for the lower a-arm where it needs to be. Looks promising for a 7" ride height measured at the rocker panel pinch weld. Might go as high as 7.5 is wifey thinks this is too low.

The jig in the picture is just to hold things in place and allow me to match centerlines, wont actually be used in the structure.

The upper a-arm has a slight interference with the outside of the frame in the red-marked area. Maybe 1/2" So, I figure if I bridge the gap at the bottom, I can pretty mcuh do what I want with the area above it so as to create room for the upper a-arm.

this leads to the next question: Do I want to make a removable K member or just weld the pick-up points permanently into the Vovlo frame? A removable k member might let me drop the car over the enginerather than craning it in all the time making life easier. Therei s lots of room side-to side in the bay.

Heck, I'd make a removeable K member that bolts to the Volvo frame rails. Remember also there's no rule that says the Miata lower C/A bushings can't be moved a couple of inches closer together too.  The Beardmore Bros in Britain swapped Miata stuff under a Morris Minor, that's what they did to gain a little room.

The Beardmore Bros in Britain swapped Miata stuff under a Morris Minor, that's what they did to gain a little room.

Ian F

UltimaDork

11/12/13 7:50 a.m.

Hell, if you can make a bolt-in front cross member that uses Miata bits and steering rack, be sure to build a jig to duplicate it... I might buy one.

NOHOME

Dork

11/12/13 10:54 a.m.

Ian F wrote:

Hell, if you can make a bolt-in front cross member that uses Miata bits and steering rack, be sure to build a jig to duplicate it... I might buy one.

The idea is there already guys...

Interestingly enough, using the Miata location vis-a-vis the engine straddling the cross-member, solves or at least mitigates some of the documented issues regarding the 302 swap into this car.

The 302 swap using Volvo front suspension forces the engine way back into what is already a short engine bay.

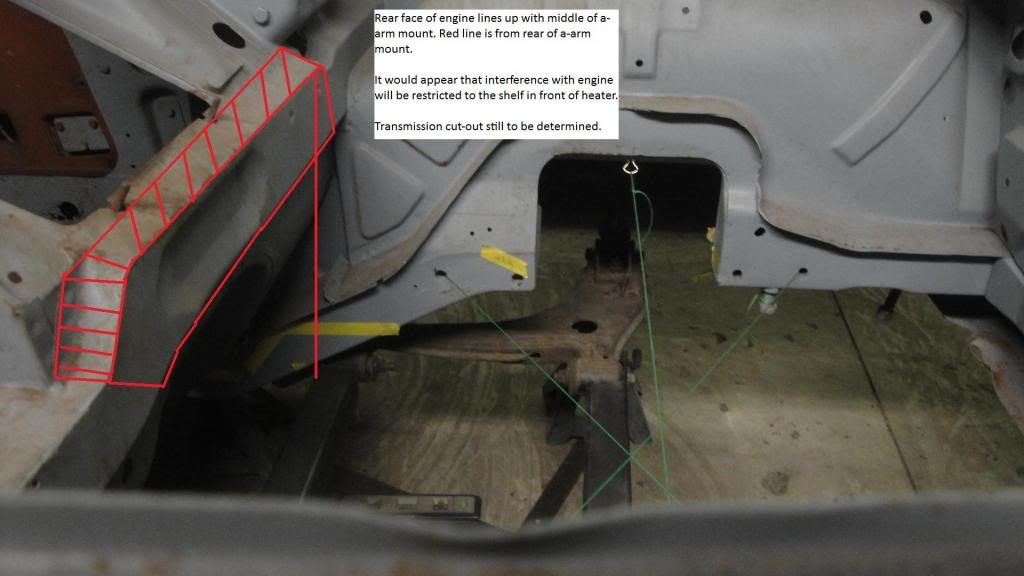

Using the Miata suspension hard points puts the rear face of the engine right in the middle of the rear mounting point for the lower a-arm. The firewall intrusion should be a matter of an inch of two. Might even have the option of keeping the stock heater system (if I want)

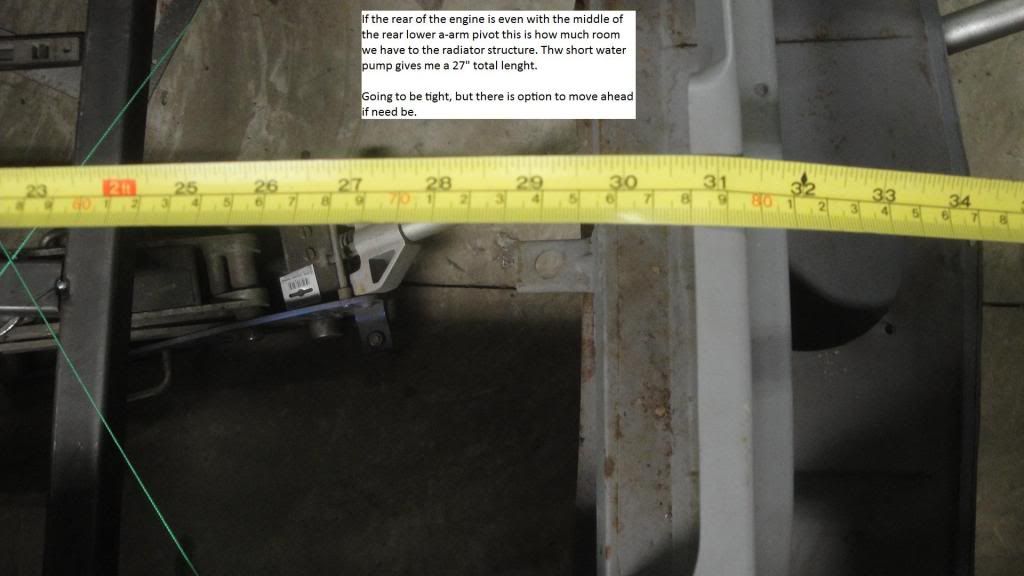

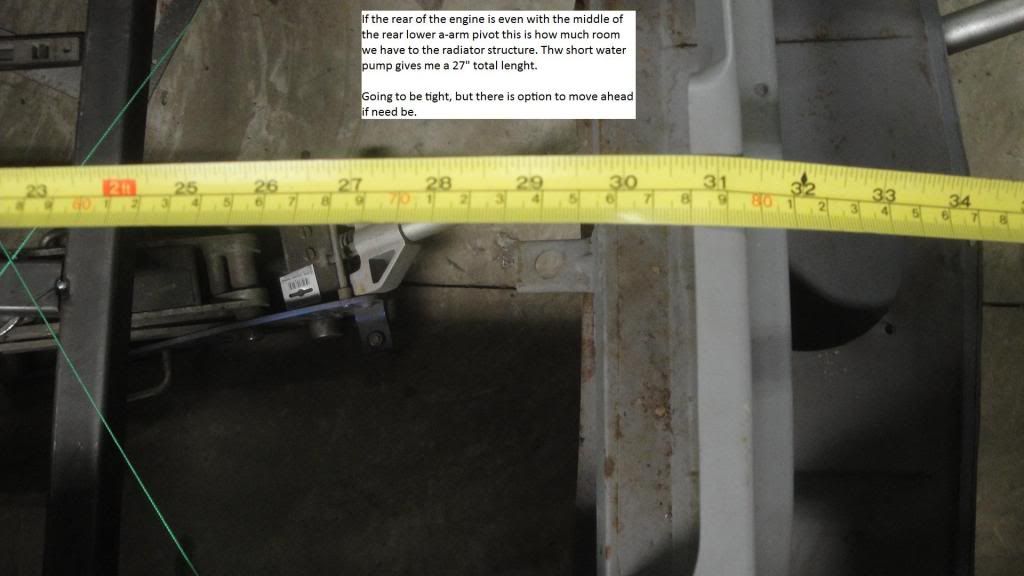

I think that leaves enough room to get a rad up front if I use the ford motorsport short water pump with matching front cover.

The short pump puts me just under 6" from the front face of the 302 block

Need to build some stands that put the car at the ride height I want so I can zero in on the exact mm where I need to cut, (or weld) then jig the car over the surface plate and go at it.

It is a good time to calm down and be paranoid about everything while thinking about the next 50 steps.

would like to thank Mark Waring, TxDarth and CVX 20 over on the Miata conversion forum for the pictures of their work.

Ian F

UltimaDork

11/12/13 12:37 p.m.

I forgot about the Miata shock towers... which are part of the bodywork on a Miata. While a bolt-in cross member may be doable for the control arms, I'm not sure there's any way to bolt-in the upper shock/spring mounts under the 1800 without cutting. Hopefully I'm wrong.

Granted, all of this has been done:

http://swedishops.com/

NOHOME

Dork

11/12/13 2:17 p.m.

http://i1063.photobucket.com/albums/t520/NOHOME1/DSC06133-2_zps607a26ca.jpg

http://i1063.photobucket.com/albums/t520/NOHOME1/DSC06133-2_zps607a26ca.jpg

The space available looks like it will accommodate an engine that is 26.5 long by 18.75 wide. I should be able to drop the car over the engine with the room available.

I am not sure what space exactly will be eaten up by rad and fans. I have a few inches in front of the theoretical water pump snout and 20" by20"of free area in the rad opening.

Peter

NOHOME

Dork

11/12/13 2:23 p.m.

Ian:

There will be some form of cutting since the upper control arms need to occupy some simultaneous real estate with the space either side of the Volvo frame notch. I don't see where the shock towers pose much of a design challenge to integrate into a removable crossmember.

Well aware of the 5k plus suspension kit you show.

It has a few flaws in my mind:

1- It is mustang derived. Generic as can be for use on any random hotrod and optimized by none.

2-Cost! 5k plus shipping plus import duties plus 13% tax.

3-It's a "Bitsa" design. Bits of this and bits of that...10 years from now when the second owner from you needs parts or specs for that front end, where do you start? Fine for a disposable race car, but not for my design intent. I would like to be able to rip the corresponding sections out of a Miata manual, a P1800 manual and a Ford 302 manual and have a proper technical manual for the finished car.

4-Still jams the engine way back into the car same as the Volvo crossmember.

Don't get me wrong; I can't fault the work or the performance potential, but I have no way of doing any due diligence on that front end.

Last of all, where would the fun and challenge be in bolting that to my project? Lets not forget that is why I am doing this in the first place. More into this for the project challenge than the finished results.

Ian F

UltimaDork

11/12/13 2:47 p.m.

In reply to NOHOME:

I have no love for Robert's design either... just putting it out there as an example.

He stead-fastly refused to offer geometry data when asked about camber curves and bump-steer and would only state "it has been addressed..."

I do disagree about parts availability. His kit uses standard OTS bits that will probably be available for as long as I'm alive and we're still driving gas powered cars. If you start moving the suspension points around, you may end up having to fabricate new control arms as well, even if you do keep the other wear points.

Trust me... the more I think about it, the more I'm inclinded to think it's all not worth the effort and just tweak the OE stuff.

NOHOME

Dork

11/12/13 3:05 p.m.

Ian F wrote:

In reply to NOHOME:

I do disagree about parts availability. His kit uses standard OTS bits that will probably be available for as long as I'm alive and we're still driving gas powered cars.

IF you know where to go looking for them and they are not obsolete items. The a-rams, bushings and bearings are from unknown suppliers and would require the abilities of a fabricator to source if only to make sure you are asking for the right parts.

Ian F wrote:

If you start moving the suspension points around, you may end up having to fabricate new control arms as well, even if you do keep the other wear points.

Trust me... the more I think about it, the more I'm inclined to think it's all not worth the effort and just tweak the OE stuff.

I refuse to muck with the Miata geometry. Making it wider or narrower opens a can of worms that I am not equipped to analyze or predict. I am already messing with a CG, ackerman and weight that was never meant to be parked on the Miata suspension.

Ian, you are an engineer and I assume familiar with the 4 gate product development cycle. At every gate 1 meeting there is a person who has very good reasons why the product or project should never be started; mostly risk based or technical uncertainties that they don't see economical solutions for. There is always another person or group who is arguing that the fruits of the effort will be worth the risk. Neither group is wrong if you think about it. I think you and I would be on opposite sides of that argument.

Picture below belongs to this beautiful project using Roberts suspension:

http://forums.swedespeed.com/showthread.php?175204-1968-Volvo-project-Pure-Volvocity

Well worth the read. Wish I had his budget, I would buy an Elise!

These look like they might fit the bill. I like the 42 mm offset since I would rather space out to fill fenders or miss chassis than flare fenders.

These look like they might fit the bill. I like the 42 mm offset since I would rather space out to fill fenders or miss chassis than flare fenders.

good day in the shop today. Had some good friends from the LBC community come by toinform me that I am insane.

good day in the shop today. Had some good friends from the LBC community come by toinform me that I am insane.

http://i1063.photobucket.com/albums/t520/NOHOME1/DSC06133-2_zps607a26ca.jpg

http://i1063.photobucket.com/albums/t520/NOHOME1/DSC06133-2_zps607a26ca.jpg