Honestly, i began doubting my methods last night. So i got methodical this morning. Initial anomalies led me to believe that somewhere under the high temp sheathing to b2s1, there had to be a short. When i cut the sheathing, i found three spots that the wires were fused together. i cut out damaged section (about 6 inches) and spliced a spare female oxegen sensor socket in.

these are my super methodical results. this is all B2S1 AFTER rewiring from the firthest damage found. depending on what y'all say, i may need to start at the DME connector itself with rewire.

multimeter settings on my bosch multimeter

ohms 20m

volts 20vdc

battery voltage at the jump points in the engine bay: 11.29

ohms of wires between oxygen sensor plug and DME done with DME completely disconnected.

voltage done with DME connected and key in run position

ground test done with DME connected, key off

x6002 connector pin/wire color/purpose per tis/v/ohm from female 02 socket to dme/ground ohms to jump point

13/brown/B2S1 ground/3.95v/.5ohm, showed on signal as well/zero ohms to ground

15/yellow/B2S1 signal/.42v/0ohm/.04ohm

21/black/B2S1 heater ground/0v/2.0ohm

??/red/wht tracer/power?/11.17v/0ohm to ground

im completely baffled by these results. hopefully one of you can find fault with my lethodology while I pull the DME and open it up for visual inspection

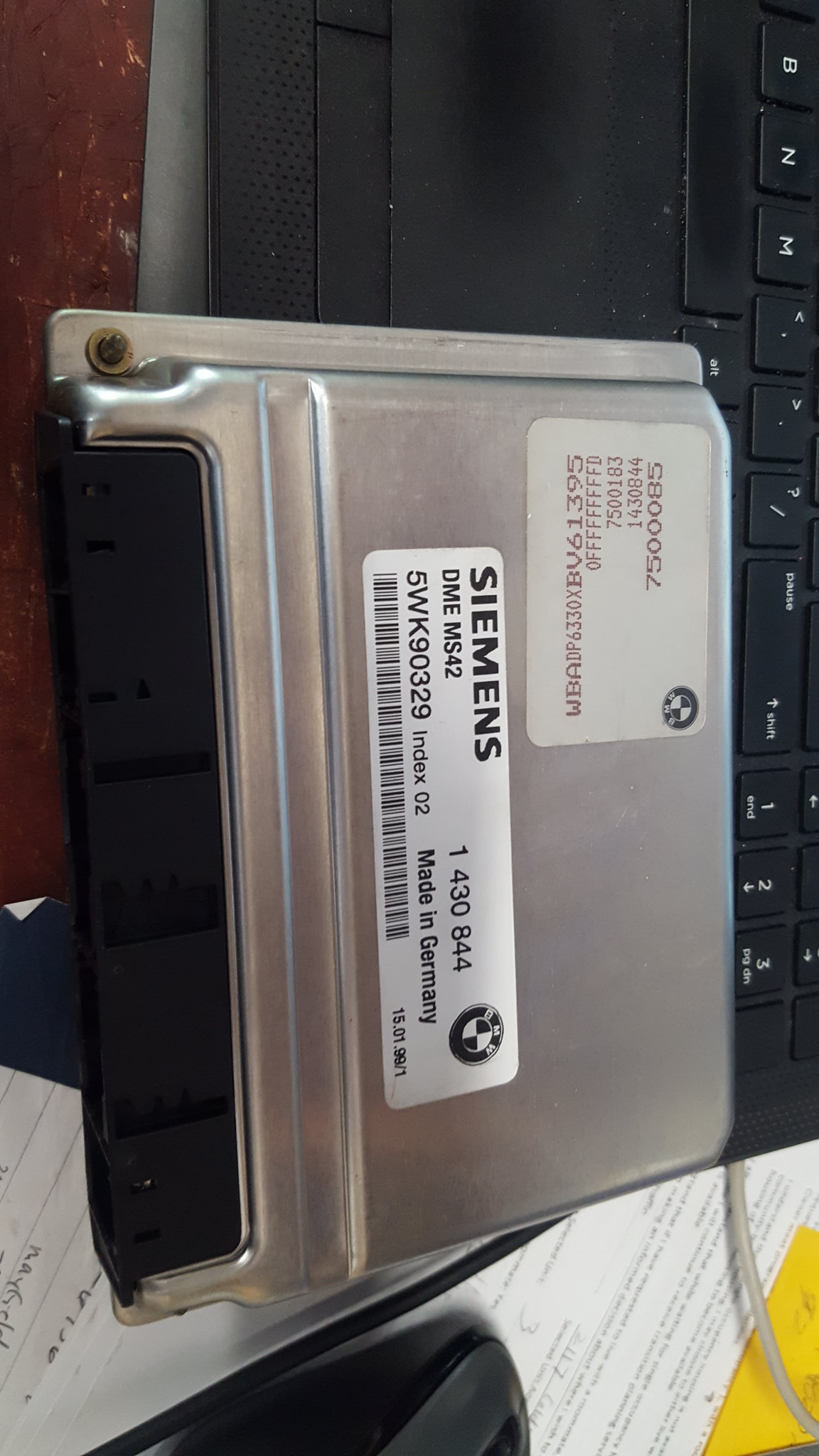

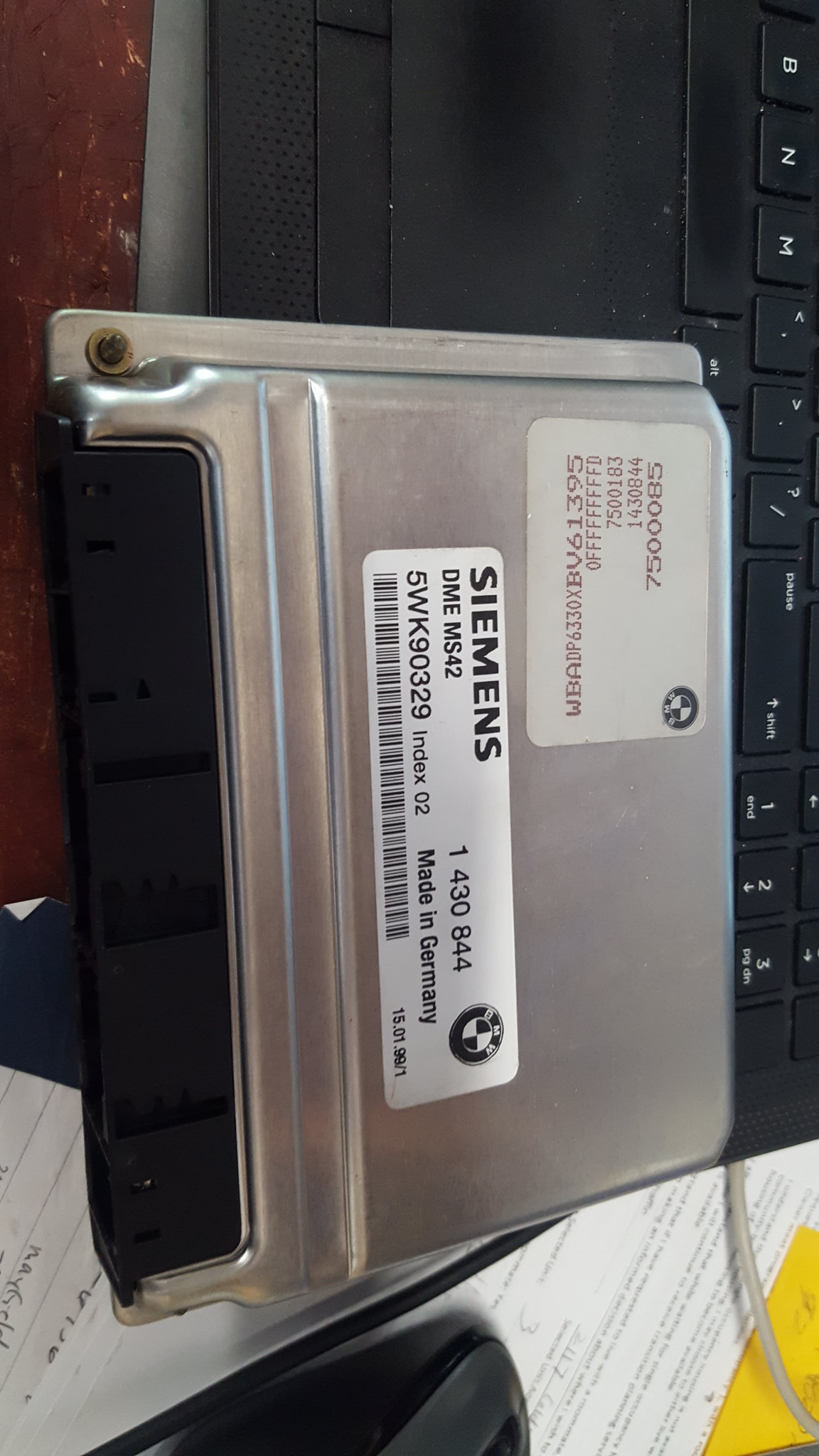

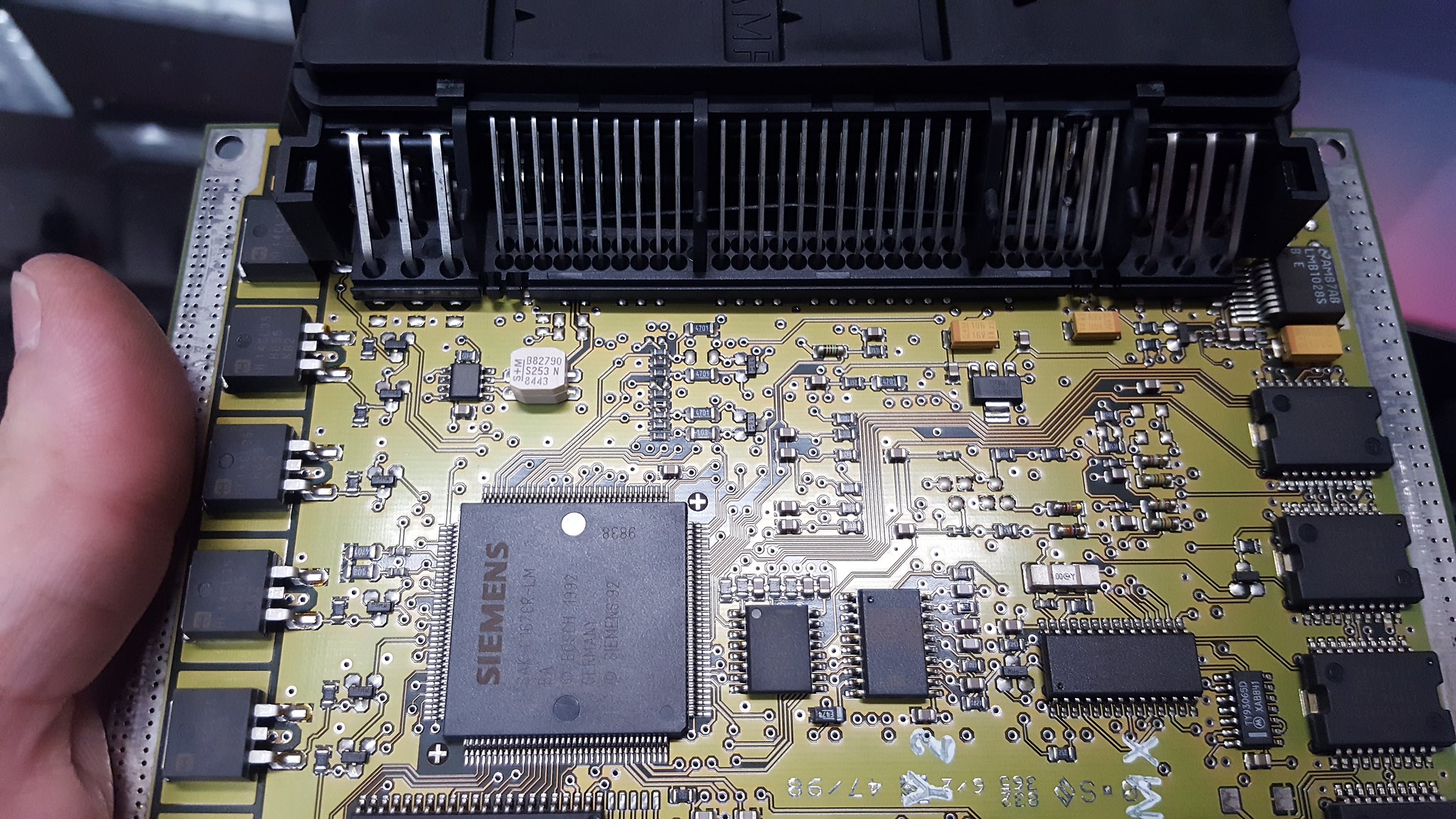

the following pictures show my DME. first is trhe case numbers, so we can confirm if its even the correct one.

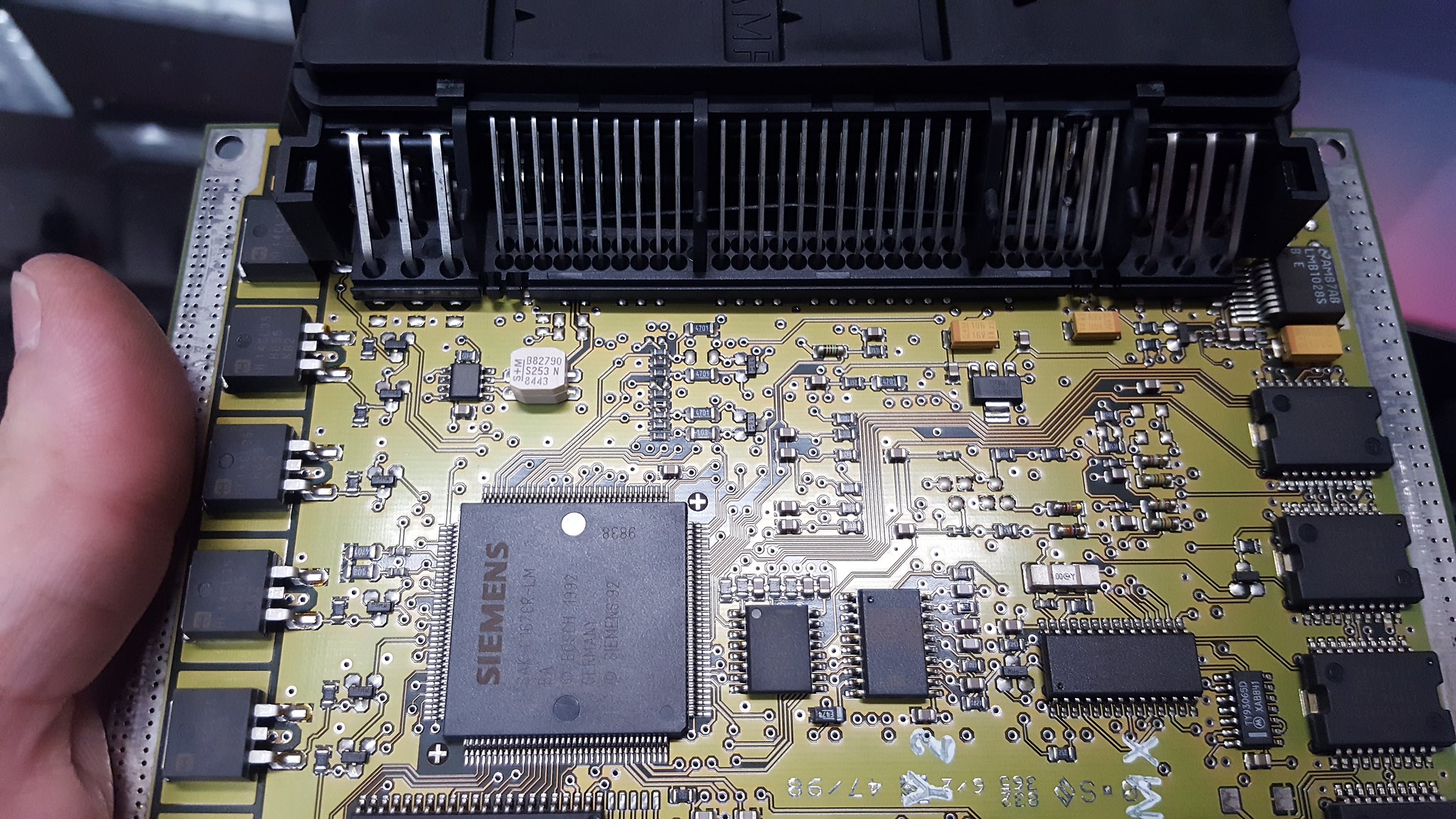

second, which is hard to make out, shows pin 21 completely melted, and pin 15 crispy. pin 13, however, shows no signs of damage. nor does anywhere else on the board show obvious damage. i can almost make myself believe that there are some unhealthy solder joints on the board, but its more likely contaminants in the solder giving brown spots.

so i believe i need a DME at this point. how do i go about getting the correct one, with correct programming? is there something special i need to know? remember, my experience is with obd1 GM and megasquirt.

20180826_114852 by Michael Crawford, on Flickr

20180826_114852 by Michael Crawford, on Flickr

20180826_115231 by Michael Crawford, on Flickr

20180826_115231 by Michael Crawford, on Flickr

That blown pin can be fixed. It's nice that it's not buried in there. If you have any thru hole capacitors or resistors with long leads on them you can clip the lead off and solder that to bridge together your blown out pin.

The brown stuff on pins/pads of the voltage regulators (black 3 pin squares on left side of your picture) I'm 99% certain is just solder flux from the manufacturing process.

I thought about repairing the fried pin. Is there the possibility that it could do mpre damage to things once repaired?

Dusterbd13 said:

I thought about repairing the fried pin. Is there the possibility that it could do mpre damage to things once repaired?

Possibly, if the wiring is shorted somewhere else now.

But honestly, I bet you have found your problem. My thoughts, o2 sensor shorted, melted wires in harness and that pin on dme. New o2 now not working, not because o2 itself, but because damaged connections. What does that pin go to?

If that's Pin 21 on X60002, it's the ground for O2 sensor heater on B2S1.

02pilot is correct.

I just got back from the junkyard where i got the entire o2 sensor to dme harness. I found the corresponding pin in the wiring connector to be melted as well. That, combined with the crossover between pins in my "after repair " test makes me question the integrity of the whole sub harness. So, thats next. But 5/7 Silverado, broken rib, and road work for 60 miles says im done for today.

While waiting for the dme to come back, i did a smoke test this morning before work. It went to show that i need a better way to introduce the smoke into the system. Duct tapeing a spray paint can lid to the maf, drilling a hile, and jamming the tester in wasnt very repeatable or reliable. I did see some smoke at the ccv where the valve cover hose meets. Disconnect and reconnect made it go away, but with how much smoke was coming from the maf it may have been a red herring.....

I also got the 02 sensors harness wired in. No crossover between pins anymore!!!!

All the tests show what i would expect from a properly functioning harness and connector. On all 4 sensors.

02Pilot

SuperDork

8/30/18 9:04 a.m.

Dusterbd13 said:

While waiting for the dme to come back, i did a smoke test this morning before work. It went to show that i need a better way to introduce the smoke into the system. Duct tapeing a spray paint can lid to the maf, drilling a hile, and jamming the tester in wasnt very repeatable or reliable. I did see some smoke at the ccv where the valve cover hose meets. Disconnect and reconnect made it go away, but with how much smoke was coming from the maf it may have been a red herring.....

Get a spare oil filler cap, drill it, screw in a brass nipple (seal with epoxy if you think it's necessary), and pump away.

How to seal off the maf? Obviously duct tape aint it.....

02Pilot

SuperDork

8/30/18 9:32 a.m.

No need - the throttle plate should seal. If it doesn't, pull a rubber glove over it.

Awesome!

Should i leave the hosing to the maf and Helmholtz resonator in place to test those as well? Im assuming not, but every time i assume something with this car, it bites me in the ass.

leaned the residue from the maf.

Drilled an oil fill cap to fir my smoke test probe, set my air pressure regulator to 3psi, plugged off the intake tube at the maf and the exhaust pipe with rubber gloves and zip ties, and let it run for about 15 minutes.

The only smoke visible was from imperfect rubber glove seals. I could find NOWHERE else.

Is there a problem with my methodology tjis morning, or am i doing it right and have no vacuum leaks?

Dusterbd13 said:

Is there a problem with my methodology tjis morning, or am i doing it right and have no vacuum leaks?

bro, it's a 20-year-old BMW. nobody in their right mind is going to say "no vacuum leaks". ;-)

Lol. Would it be safe to say I have a minimum chance of it any diagnosable vacuum leaks

so, time for round 2.

i have confirmed that all the wiring to the 02 sensors are good now, and replaced the DME with one that isnt melted, and has all the updated software applied. car runs really great. except....

the new CEL behavior is very strange. on the first drive cycle with the new DME (26 miles) there was no check engine light. shut the car off briefly, fired up again, and when the car hit ~20 MPH the CEL came on. P1188. this behavior repeats itself regardless of length or type of first drive cycle from code clearing. example: cleared code, drove 3 miles to gas station. refire, code. clear code, drive 140 miles with no issues or CEL, refire, code back.

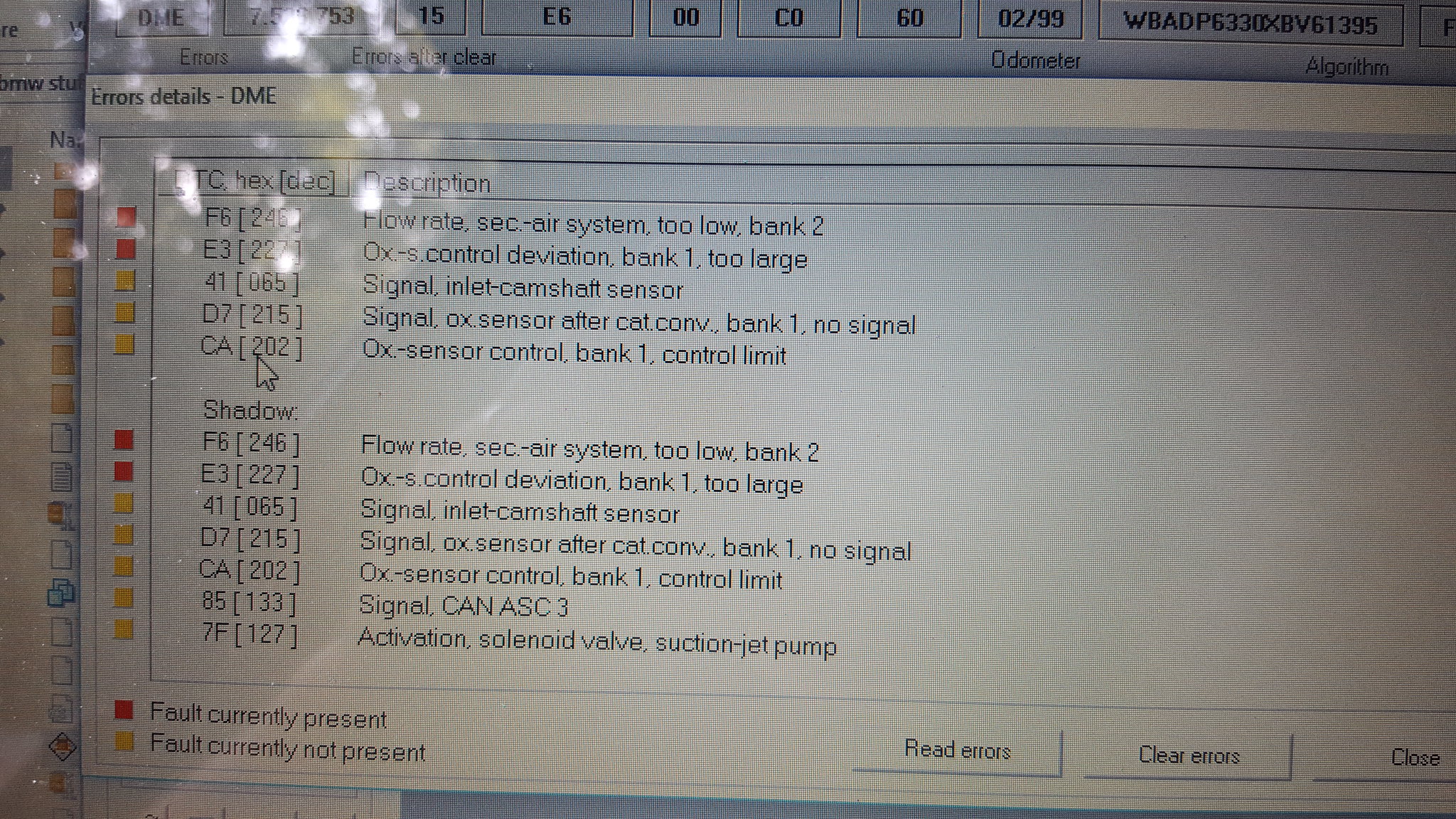

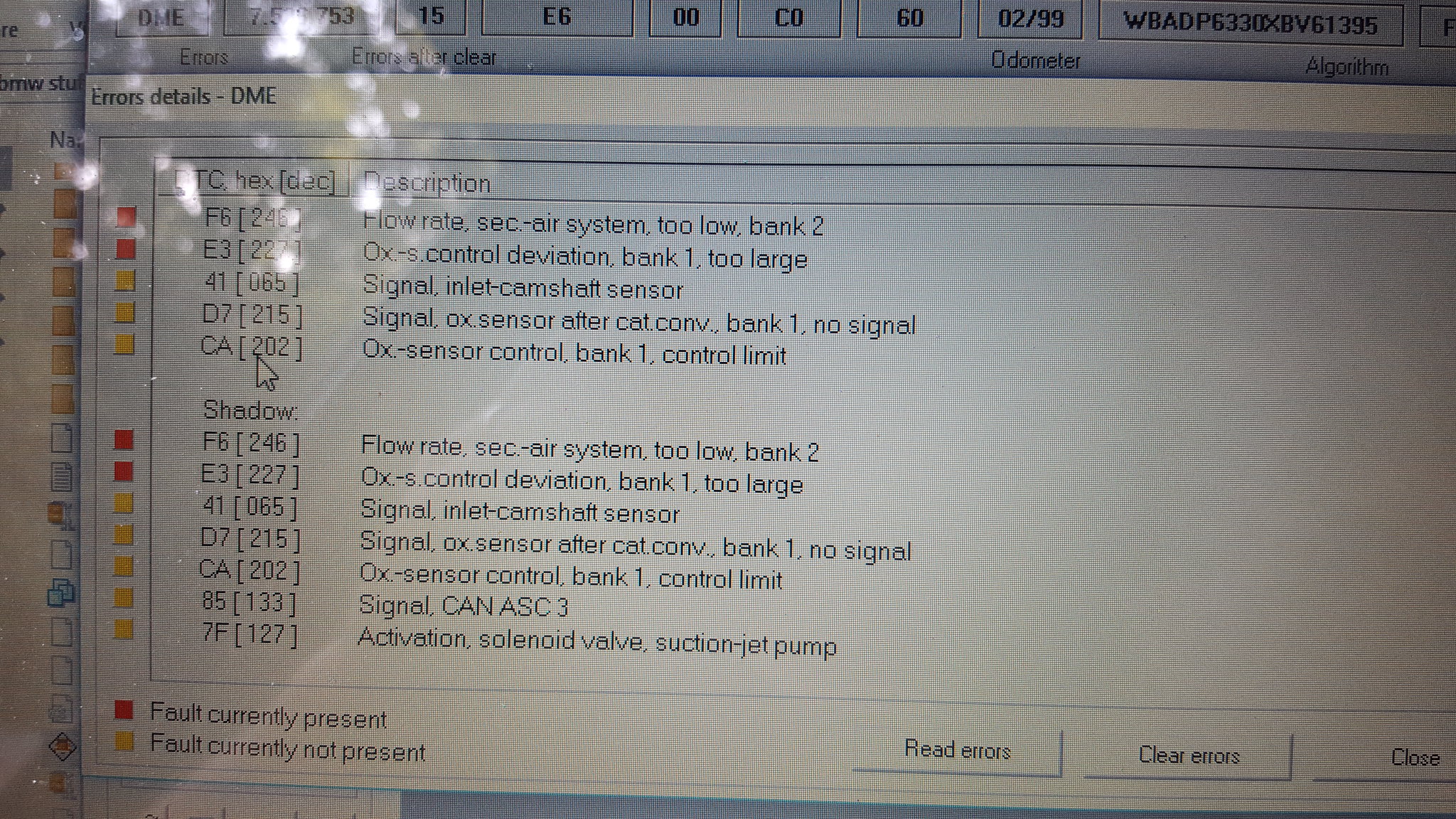

i hooked up the BMW scanner, and got the following codes (red boxes are current, yellow are shadow, whatever significance that holds.)

20180908_173203 by Michael Crawford, on Flickr

20180908_173203 by Michael Crawford, on Flickr

where do i start now?

I think it is normal for the cel to fire on the second key cycle even if the error is immediately present.

There is still something going on with that bank 1 o2 sensor it looks like. What is the secondary air system? A pump? I'd also probably throw a junkyard (or borrowed and known good) intake cam sensor on it.

Secondary air system pumps air into the exhaust at start-up to get the cats working faster. Check the plumbing for air leaks - they're pretty common.

Fire isn't an option Patrick.

Secondaryair:

I found the plastic tube from pump to valve is mostly made out of electrical tape. But i need to pull the bumper to change it i believe. Im thinking heater hose.

I also wonder if the valve or tubes may be full of E36 M3. That was common on gm stuff. Possibly here? If so, can i pull it with engine in car?

The intake cam sensor seems to be a completely new code. Jim replaced the exhaust one before i got the car. I found a way to test, but has to be done on a cold engine. I drove to dads place to use the lift. So that will wait. I will pull the connectors and clean all ther terminals though. Simple fis first.

Bank one oxygen sensor i missed on all the previous diagnostic. I had target fixation on bank 2. That ine has to be the sensor or something other than wiring and dme. Im certain of that.

The secondary air pump can be tested through the diagnostic computer. I wouldn't use heater hose there - too close to the exhaust. The OE replacement shouldn't be too expensive. Note that there are also a series of smaller hoses running back to the intake manifold that should be checked.

I unfortunately don't have a diagnostic computer that will fire off the pump. Understood on heater hose. The lines running back under the intake are you referring to the vacuum lines?

02Pilot

SuperDork

9/9/18 10:30 a.m.

Huh. I would have figured your software would be able to do that. In any case, you can usually hear it kick on during cold starts, then off after a minute or two. If you're not hearing it, check voltage and ground before yanking it out.

Yes, I believe the small diameter lines are vacuum.