Jason lives near me. I have a custom Enthuza exhaust on my turbo Miata & can vouch for his work. His day job is building military aircraft, so he knows his craft.

Jason lives near me. I have a custom Enthuza exhaust on my turbo Miata & can vouch for his work. His day job is building military aircraft, so he knows his craft.

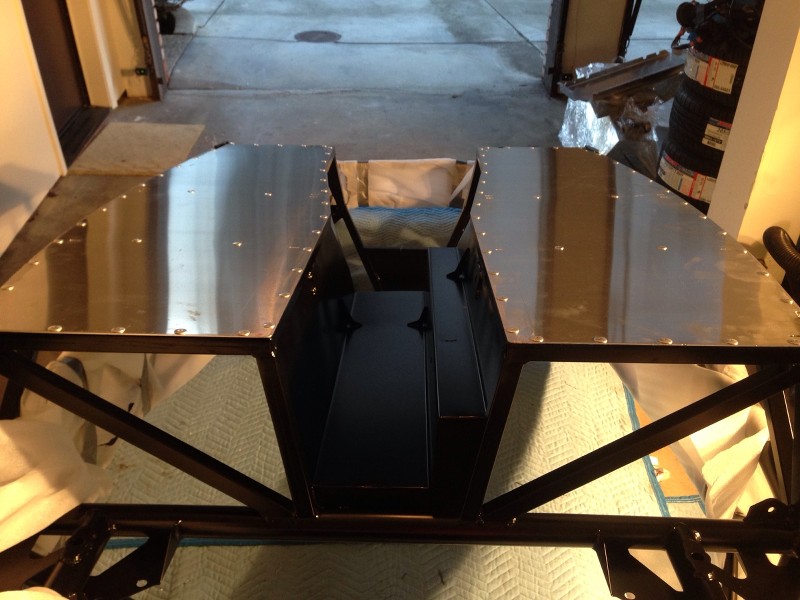

Well, hello there hood buck skeleton. Nice to meet you. We're going to get real acquainted over the next few weeks.

Now back to the lasercutters to get our new jig table!

(Fun fact, etching part numbers doubles the CAM time, so these prototype pieces are identified by shrinking lofted shapes. I can easily compare the size of those circles to put the parts in the correct order. It's a whole lot faster than CAD-ing a cut part number on every piece.)

Edit: I got impatient.

In reply to SteadFast:

According to the FM build diary (http://flyinmiata.com/exocet/FMX/index.php?UID=25), they are using the VMaxx. Not sure what height they would suggest for setting, as they are still likely developing the car.

Any good photos of the front suspension mounting points, on the production frame? I'm curious to see if the front geometry is still horrid, or if that has been updated. Or if there is at least room to properly locate the inner points for the upper control arm.

Thanks,

Chris H.

^From what I understand, it uses the Miata subframe, which IIRC the Miata subframe has the upper/lower mounting points for the control arms.

Yup. Miata subframes, Miata geometry. I believe the upper shock mounting point is very slightly further inboard, but that has no real effect on anything.

We are using the VMaxx on the build at FM, and they've been used on other builds in the past.

Yeah, see the big empty space at the front and rear of the frame? That's where the Miata subframes sit. The shock tophats mount a little inboard of the Miata positions, but that does not affect how the upright moves, just the motion ratio. The motion ratio change is tiny (<5% in the absolute worst case), if you're worried about that. No need for pickup points on the frame. We don't even have any plans to make tubular subframes, as setting up all those pickup points with five dimensions of constraint in a production-friendly jig is less fun than we want to have right now. ![]()

If you're asking about the subframe tilt and resulting bump-toe relationship, that was fixed in the US version of the frame. I may be the only person that actually cared, though. I also don't like the AP1s rear suspension geometry...

Then it must be the height of where the stock subframe is mounted to the Exocet chassis. Are you having to lower the suspension through it's movement, in order to obtain a low enough ride height? The angle of the upper control arms is just terrible.

This is kind of the worst case condition:

I realize this car was slammed, and put together in a limited amount of time. But comparing that to a slammed Miata, and the control arms aren't even in the same neighborhood. It is just comical how bad that is.

Any shots of where/how the stock subframe mounts to the chassis?

In reply to subrew:

The springs on those coilovers were 2" shorter than they were supposed to be, and we didn't have time to get anything longer. The AFCOs allow for that much articulation, because rally car.

Remember, we went from bare frame to racing at VIR in four days! XP-3 was riding lower at VIR than any Miata ever should. You're seeing articulation here that would put a Miata's frame rails on the ground. XP-3's front subframe was about 3/4" off the ground until she got the correct springs. The front wing mounts are supposed to sit 5" off the ground at a "performance" ride height. They were, um, maybe 1.5" here. She was also running about 160 whp at VIR too, as the donor's coils were too tired for boost. I agree, comically bad, but it was good enough for a 2:15 out of the box with no alignment, setup, or tuning. It was an exercise to prove that you can slap one of these together really quickly. This year, well, hopefully we'll see what a sorted out Exocet can do.

Here's a picture that shows the intact front subframe and its 8 points of contact. The rear is attached the same way. I hate to question your familiarity with the Exocet, but have you skimmed the first 5 or so pages of this thread? I feel like the "rollerskate" concept has been articulated pretty well. Anyways, the middle points are designed to deform in a controlled manner to ensure that the bellhousing/engine travels down and away from the passenger compartment in a massive frontal impact, just like the Miata. It's really hard to see the subframe in most pictures, actually. We should build one with CAD-model-style colors, bright colors for every major component to show off the Miata parts...

Warren v wrote: We should build one with CAD-model-style colors, bright colors for every major component to show off the Miata parts...

Good thing you have a powdercoater :) Visually it might be a bit of a mess, or it will work well, like the old harlequin (sp?) Golfs.

We've mentioned tripling our welding station capacity. Here's a quick explanation.

(Every time we walk by this thing we may or may not make the Whomp noise from Super Mario 64.)

(Every time we walk by this thing we may or may not make the Whomp noise from Super Mario 64.)

Welding Station #1 is the same as our current jig table, except it has a new, thicker top with a few more features. It's made out an exotic Norwegian steel that's supposedly more impact resistant than even DOMEX. Have I mentioned how awesome it is to have a laser-cutting partner that does all sorts of cool stuff with exotic materials?

Anyways, we'll be able to locate all four front subframe mounts with it, it simplified the clamping hardware dramatically, and the big hole in the center allows for more comfortable welds on the inside of the frame. As a bonus, it has the shape of the mid-level tubes laser-etched into it for our initial jigging setup. The entire top half of the car is designed to be welded while attached to this table, which means less distortion than the normal method of tube frame assembly.

The frame of weld station #1 is being laser cut as I type this. We'll weld that on a friendly nearby company's precision jig table, which is a giant 4" thick slab of precision-ground steel. We did the same thing with the original table.

Welding Station #2 is coming to life today! This is where we'll put on the floors and bulkheads. I let our new GT Co-Op Tyler go hog-wild with the design/build of this station. It will feature shaped wood blocks/yokes and simple clamps to hold the frame in place.

Welding Station #3 will simply be our current jig table. We'll place the completed frame right-side up, do the required grinding for aesthetics, and weld in things like the harness mount tabs.

I am at rolerskate point now. 3 days at 5 hours one 10 hour day made it a point NOT to use any air tools worked entirely by myself up to the point body came off. I could defanately cut 5 hours off doing another strip down now that ive done one. 2 descent mechanics in a good shop with air tools I think its a one day project. Just wanted to share.

Lego cars, brother. You're done with the hard part. ![]() We ain't lyin about the build times.

We ain't lyin about the build times.

Flyin' Miata claims 90 minutes on a Miata teardown. Not sure if I believe it?

I got distracted installing a new 2 post then a new 4 post lift, & was super detailed labeling everything. It was also my 1st Miata tear down. H2O cooled VW half a day day solo no prob. 100% if i/we build another at the shop it will be 2 person job 2 weekends possible to do entire build. Keeping focused around over a dozen custom builds is hard to do. Now if my Exocet gets on a truck by early February I can go racing for my B-Day on 3-15 if not im going to get stuck driving a Lotus.

Warren v wrote: Flyin' Miata claims 90 minutes on a Miata teardown.

Is that Keith blindfolded with an arm tied behind his back? ![]()

I'm not sure I ever made that claim - at least, not seriously - but it would be a fun target to aim for. Should be possible with a couple of guys. Give me Kyle, he's roller-skated more Miatas than anyone. Or Bill, he never moves fast but stuff just happens.

With a lift, a couple guys and the proper tools, I can see it happen, though they'd want to be familiar with the process. Subframes, shifter big boot, brake lines, electrical connectors and steering column and you're good to go. I know that we did it in a garage, with only two jack stands and an engine hoist in 3 hours, and that was with a partial set of sockets. That wasn't particularily fun. Lots of crescent wrench use.

In reply to 4cylndrfury:

Behold. Jig 2ble: The Reckoning

We also have that pavement stuff at our final location now. Nice feature.

In reply to Warren v:

Hello, I have found your spreadsheet very interesting. Is the Spreadsheet/Excel file available somehow, or you can send it to me directly?

Very nice job done there!

We've got a customer in California that's keeping a build thread going. In less than a week of spare time he's gone from delivery to roller. Always encouraging to hear such positive feedback.

On the aluminum panel mounting:

steadfast said: This was very easy and took less than 30 min or so. For those that don't know, the US Exocet floors come precut with drill guides already included. It was as simple as drilling out 70-80ish holes and then riveting them all. I did run a heavy strip of silicone to prevent the rattles. This weekend I plan to run the gas and brake lines. And then mate the new body to the roller skate. Some quick thoughts... #1) The welds looks incredible, and the fit finish blows me away. #2) Very happy with the powdercoating, flat black looks great and will go great with my championship white body panels. #3) This truely is like adult legos, all that is needed is to follow the steps and have a basic understanding of tools and automotive workings.

Feel free to follow along here: http://mevowners.proboards.com/thread/4507/steadfasts-california-exocet?page=2

The rock climber in me says that suspending that car by the yellow strap in that fashion imposes a tremendous "pinching" force on the two top tubes. Referencing one of my climbing manuals, since the angle of the strap is greater than 120 degrees, each of the two tubes is experiencing a load greater than the entire weight of the roller. Sure, it is "just" a roller but that's still a considerable weight, and the photo is a testament to the strength of the Exocet frame.

If I were going to lift the car using the engine hoist, I would put two straps across the frame, each where there is a cross tube. Then connect those two straps with another strap and attach the lift to that third strap. An additional benefit is you can then adjust where on that third strap you lift, allowing the car to hang level.

My way might be unnecessarily safe but rock climbers feel warm and fuzzy when their anchors are unnecessarily safe. ![]()

In reply to DWNSHFT:

Yup, that angle would have ripped my SLCDs out too. ![]()

I had the same knee-jerk concern, but mental math only showed about 300 lbs in each strap assuming a 70° angle. That frame is about 195-200 lb with the aluminum in. If he had hung it at the middle of that top swept tube, I'd worry about making some small dents when bouncing it around, but those nodes are a good place to put a lot of force. I'd only worry about damaging the powdercoat with that much pressure.

Granted, if I were doing this, I'd throw some bolts in the center seatbelt mount holes and hang the frame off that. I've never had to do this alone; usually one other person is enough to get it set on the rollerskate.

You'll need to log in to post.