Dashpot

New Reader

4/15/10 12:20 p.m.

I've about had it with my cast iron manifold and stretching turbo studs (FMII turbo Miata). I can't get more than 1 track day/TT in before needing to retorque, but all that does is stretch the studs to failure the next time out. Last time I replaced the whole manifold & stud assembly, clamped the downpipe, and used Stage 8 lockers - results were the same, very frustrating. So much for Plan A.

Plan B - I want to have a welder lay a couple of 1/2" long beads on the manifold/turbo joint, right on top where I can hit them with a cutoff wheel if necessary. I realize this is not a recommended practice, but I'm really sick of the conventional methods not working, and really don't want to shorten another day at the track when my turbo falls off. Also frustrating, and embarassing.

I have MIG & TIG available at work, but our welder isn't experienced with welding cast iron. Does anyone out there have experience with C.I. welding? Turbo's in particular?

i'm no expert at turbos, but would it make sense to drill and tap the manifold and turbo flange for a larger diameter bolt first? it may take the apparent pressure better and fix the problem. if you solid weld the units and you have a pressure build up that the turbo and wastegate cant dissipate (which may be the underlying issue) then it seems to me the pressure problem will just go to the next joint down the line for a bolt failure. that next joint would be the manifold to head connection which would take a lot more time and work to fix at every failure. just my $.02.

There's a lot of factors at work here, and I agree with itsarebuild that your problem may only be manifesting itself as stretched studs. Once you improve the weak link, the next weakest link will break. How much boost are you pulling? How much heat? The heat could be causing your problem, thermal expansion and contraction of the joint could be causing it to come lose. Also, what grade of fastener are you using? Bolts, nuts, and studs are (believe it or not) very highly engineered pieces, and the correct part must be selected for the application.

I hope and pray with both hands over my heart that you are not using split, star, or any other kind of crappy "locking" washer with your nuts. Torque should keep the joint together, but in instances of high vibration a proper locking device (the Nord Lock is the only one I know of) is acceptable.

Again, agreed with itsarebuild, if everything's OK and you're simply stretchng the stock studs, I'd go to the next larger size stud, or increase the number of studs. Welding the manifolds is tricky, time consuming, likely to goof up the mating surfaces, irreversible...well just don't go there.

Raze

HalfDork

4/15/10 12:50 p.m.

If you're pulling so hard you're stretching the studs, I'd ask yourself how much preload you have on your exhuast? Sounds like you're putting way too much torque on those studs which means exhaust is either too loose or preloaded to hell, easy to remove by having a flexpipe installed.

The reason I say this is we've cracked an exhaust header with our 3" exhaust with lots of preload and no flexpipe hanging an unsupported Holset off the standard cast iron mani designed for a T3.

Soma007

New Reader

4/15/10 12:51 p.m.

Have you tried the FM exhaust brace? Seems like its a new product designed to fix exactly what's happening to you.

http://flyinmiata.com/index.php?deptid=4524&parentid=0&stocknumber=06-97575

I'm going with Bad Idea. You really don't want to go that route, especially with someone who doesn't specialize in that exact thing and in a high heat area like a turbo. Add in that if it isn't really heat treated properly afterwards, it will crack either at the weld or next to the weld. I don't think you can really properly heat treat the turbo after it's welded without destroying the various seals at a minimum.

Are you sure the studs are stretching and that you're not pulling them out of the exhaust manifold? Either way, larger studs is going to be the way to go.

Lotus uses high temp stainless locking nuts, studs and stainless lockplates bent up to lock the lock nuts. They don't come loose. Sometimes even when you want them to, but that's a different topic.

Is this whole thing supported properly? Do you have vibration tearing this apart?

tuna55

HalfDork

4/15/10 1:22 p.m.

Just when you've written him off, he comes in with serious engineering like this. He's exactly right. Pick the right regular fastener and torque it to the right torque. In this instance, I would start looking around near grade eight lubed with motor oil, but that's just off-the-cuff.

volvoclearinghouse wrote:

There's a lot of factors at work here, and I agree with itsarebuild that your problem may only be manifesting itself as stretched studs. Once you improve the weak link, the next weakest link will break. How much boost are you pulling? How much heat? The heat could be causing your problem, thermal expansion and contraction of the joint could be causing it to come lose. Also, what grade of fastener are you using? Bolts, nuts, and studs are (believe it or not) very highly engineered pieces, and the correct part must be selected for the application.

I hope and pray with both hands over my heart that you are not using split, star, or any other kind of crappy "locking" washer with your nuts. Torque should keep the joint together, but in instances of high vibration a proper locking device (the Nord Lock is the only one I know of) is acceptable.

Again, agreed with itsarebuild, if everything's OK and you're simply stretchng the stock studs, I'd go to the next larger size stud, or increase the number of studs. Welding the manifolds is tricky, time consuming, likely to goof up the mating surfaces, irreversible...well just don't go there.

I think the problem here is not the torque applied to the studs but the heat that the manifold sees when under boost. I have seen many pictures and videos of turbo glowing red hot! I think if you heat any steel to red hot it will loose its strength. Using some other materal that can handle the heat better would be a better solution. Stainless Steel might hold up better. Do a search and you will find SS studs.

There is a Inconel stud group buy going on at Miataturbo.net currently. Look for Savingtons post. "Should" fix the issue. Seems like everyone with the vertical flanged Begi/FM manifolds runs into that issue eventually if they track the car.

You'll also find very long "stud loosening" threads over there also.

AutoXR

Reader

4/15/10 2:26 p.m.

Safety wire the manifold bolts. I have had lots of friends with similar issues and this solved them

A lot depends on exactly what is happening. Some excellent suggestions here, depending on the actual problem. Too hot? Need a higher temp grade fastener. Stretching? Need a larger diameter bolt, a higher proof strength of bolt, or more bolts. Vibration losening? Need a Nordlock or safety wire. You could try marking the bolt/nut head with a sharpie and seeing if they are turning, that might eliminate or point to that condition as the cause. If its not vibration losenging, then one (or both) of the other two remedies should get you there. BTW, I'm not sure that all Stainless fasteners are created equal, so rather than just buying off-the-shelf stainless in the blind hope that they will help, get the hard facts on temperature resistance on that particular bolt/ stud. I know stainless is not as strong as a Grade 8 steel fastener in proof load, and I think it may even be less than Grade 5.

Dashpot

New Reader

4/15/10 2:59 p.m.

jimbbski wrote:

I think the problem here is not the torque applied to the studs but the heat that the manifold sees when under boost. I have seen many pictures and videos of turbo glowing red hot! I think if you heat any steel to red hot it will loose its strength. Using some other materal that can handle the heat better would be a better solution. Stainless Steel might hold up better. Do a search and you will find SS studs.

Yup. Been through the steel studs, now been through ARP 300 series SS studs too. I'm still on 8mm but others who've drilled & tapped for 10mm are still seeing the problem as well.

splitime wrote:

There is a Iconel stud group buy going on at Miataturbo.net currently. Look for Savingtons post. "Should" fix the issue. Seems like everyone with the vertical flanged Begi/FM manifolds runs into that issue eventually if they track the car.

You'll also find very long "stud loosening" threads over there also.

Oh I'm well aware of the Inconel studs, just not sure whether it's the final solution. I've followed the threads on both miataturbo and miata.net; lots of theories, no definitive answers yet. I've been fighting this issue since I got the car 2 seasons ago.

volvoclearinghouse

There's a lot of factors at work here, and I agree with itsarebuild that your problem may only be manifesting itself as stretched studs. Once you improve the weak link, the next weakest link will break. How much boost are you pulling? How much heat? The heat could be causing your problem, thermal expansion and contraction of the joint could be causing it to come lose. Also, what grade of fastener are you using? Bolts, nuts, and studs are (believe it or not) very highly engineered pieces, and the correct part must be selected for the application.

I hope and pray with both hands over my heart that you are not using split, star, or any other kind of crappy "locking" washer with your nuts. Torque should keep the joint together, but in instances of high vibration a proper locking device (the Nord Lock is the only one I know of) is acceptable.

As I mentioned above, I'm currently using Stage 8 lockers:

http://www.flyinmiata.com/index.php?deptid=&parentid=&stocknumber=36-00000

with ARP 300 Series Studs (page 75):

http://arp-bolts.com/Catalog/Catalog.html

Yes, thermal expansion is the accepted culprit.

Dr. Hess

I'm going with Bad Idea. You really don't want to go that route, especially with someone who doesn't specialize in that exact thing and in a high heat area like a turbo. Add in that if it isn't really heat treated properly afterwards, it will crack either at the weld or next to the weld. I don't think you can really properly heat treat the turbo after it's welded without destroying the various seals at a minimum.

Are you sure the studs are stretching and that you're not pulling them out of the exhaust manifold? Either way, larger studs is going to be the way to go.

Is this whole thing supported properly? Do you have vibration tearing this apart?

Your points on welding are noted, thanks. Yes I'm sure the studs are stretching. If I upsize to 10mm it may or not help. As mentioned above, 10mm have failed for others. The one or 2 inconel 10mm installations out there have made it 1 day each - so far. The thing was supported the same as every other Miata kit turbo out there. It is now supported better, but studs are still stretching.

Soma007

Have you tried the FM exhaust brace? Seems like its a new product designed to fix exactly what's happening to you.

I built my own before the FM unit hit the market. Same principle, different materials. It will extend the life of the studs by keeping the exhaust from shearing them off (already did that too).

To their credit, FM and BEGI are both paying attention to the hardware failure complaints of their customers. In general their equipment holds up, but in this very specific instance it fails. Consistently.

Personally I think its a factor of non-braced turbos and the vertical mounting format used with those style manifolds. Heat and leverage/vibration stretch the studs and its all over.

If I was running a similar setup, I'd use larger/stronger studs and brace turbo. Of course that's untested opinion :)

My last manifold, the flange angled back towards the head and the turbo sort of sat on the flange. Didn't run into any stretch/loosening issues. All I used stud wise was stock oem honda exhaust studs that I took out of an old D series engine sitting around.

Dashpot

New Reader

4/15/10 3:16 p.m.

volvoclearinghouse wrote:

A lot depends on exactly what is happening. Some excellent suggestions here, depending on the actual problem. Too hot? Need a higher temp grade fastener. Stretching? Need a larger diameter bolt, a higher proof strength of bolt, or more bolts. Vibration losening? Need a Nordlock or safety wire. You could try marking the bolt/nut head with a sharpie and seeing if they are turning, that might eliminate or point to that condition as the cause. If its not vibration losenging, then one (or both) of the other two remedies should get you there. BTW, I'm not sure that all Stainless fasteners are created equal, so rather than just buying off-the-shelf stainless in the blind hope that they will help, get the hard facts on temperature resistance on that particular bolt/ stud. I know stainless is not as strong as a Grade 8 steel fastener in proof load, and I think it may even be less than Grade 5.

Too hot? Probably. Loosening? No. The Stage 8's do not allow it and safety wire would be redundent. The studs are not rotating, they are stretching. Others have used Grade 8 & 10 and had them fail too. They're just that much harder to extract when they break. I chose SS for it's thermal expansion properties over the hard stuff. It hasn't snapped off yet, but I'm not at all confident in it's long term future. Heat cycling fatigue, high temps, and uneven heatup between the flanges and fasteners are all suspected causes. I'm just dealing with the symptoms as best I can.

Umm..

Inconel fasteners hold the innards of turbine engines together.

Believe me, they'll be fine.

Shawn

First off, its extremely difficult to weld cast iron, I know lots of professional welders, including some that went to 4 year colleges for it and none of them will willingly weld on cast iron, as it can blow up/ spatter badly on the person welding on it.

Secondly, if heat is the cause of the problem, why not send the turbo, turbo manifold, and whatever down/up pipes you have in your system to Swaintech for coating. If it were me though, I'd also grab one of those exhaust shield wraps from DEI or whoever.

If your still having a problem after that, I'd consider a different setup, or re-design the system entirely, or just sell it and get a different car.

Andrew

NOHOME

Reader

4/15/10 7:39 p.m.

http://www.spiralock.com/

Not sure if you have been down this road before, but what I have read tels me that it was designed for yoour exact situation. High heat and vibration on turbo equipment where the temps go past the stress relief temps of steel.

Mercedes uses Titanium nuts and studs to hold turbos on the manifold on diesel auto engines.

I think Dashpots problem is with thermal/ heat expansion. Are you using a thick gasket in there? The gasket will allow for different coefficients of expansion betweene the various parts. If you tourque it down without a gasket when the flages expand at a greater rate than the studs you will streatch and break the studs. The gasket "absorbs" the expansion while mantaining a proper seal.

you want the joint to be bolted. A bolted joint will allow the 2 pcs to move indepentantly and exapnd at different rates if they are not the same material. Engine manuf's go to great lenght to make sure that the manifold and turbine housing are made from the same stuff, but if you are making a bolt on(custom) application, I would suggest a bolted joint.

The cast material used in turbo applications is of a pretty high quality, I've welded it many times to great success. Btw, I'm a horrible welder. High Moly Sil is pretty forgiving to weld, I tigged my last test piece with silicon bronze filler. The joint took over 400 ft-lbs and didn't break, so I think I did Ok.

tuna55

HalfDork

4/15/10 8:48 p.m.

ignorant wrote:

you want the joint to be bolted.

He's right. You don't want this thing welded, even if you could do it, which you can't do very well.

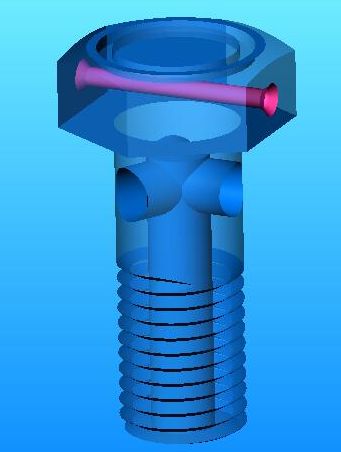

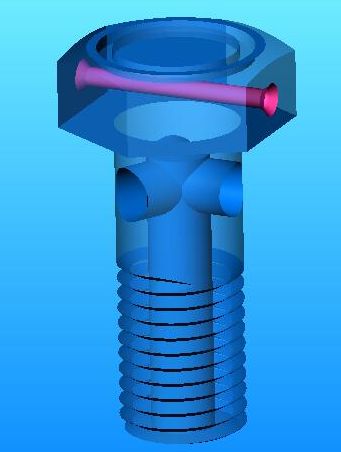

Fastener 101:

Bolts are SUPPOSED to stretch. That's what torque preload does. If they yield, they aren't big enough, aren't numerous or are being torqued too tight. Stay away from stainless in my opinion, it's weak and galls like crazy. Get bigger bolts. This isn't rocket science, if the next size up doesn't do it, go one size bigger. Make absolutely sure that stretch is the culprit, mark the thing and check it once it leaks. If rotation is the culprit, there are all sorts of ways of fixing that (although safety wire isn't the best way for this), but if stretching is the issue, you need more or bigger, period.

I apologize, I was lazy and didn't follow the link to the Stage 8 fasteners and just assumed it was marketing buzz for something worthless. It seems as though we've ruled out vibration as a culprit, with the anti-rotation devices (the Stage 8) and I cannot imagine that a grade 10.9 or 12.9 (forgot we were dealing with metrics here- my car gets 40 rods to the hogs head, and I likes it that-a-way!) in your application is stretching beyond yield. 10.9 is essentially equal to Grade 8 and 12.9 is...well, its pretty effing strong.

So it sounds like your problem is thermal. Stuff's getting too hot. Which means you either need to cool it off some, or find fasteners that will withstand the heat. I'm with tuna55- stainless is the wrong move for this application. (We actually agree on stuff sometimes, believe it or not, even though between the two of us we have over 12 years of engineering education and 15 years of engineering experience...plus again, between the two of us, I'm pretty sure we've owned one of almost every make of car ever) The Inconel should be fine, and I'd couple that with some thermal coatings or wraps as mentioned above and also check on your A/F ratio to make sure your turbo isn't spooling up godawful lean.

One last thing I just thought of: I had a horrible problem on an old slant six Dart with blowing out exhaust downpipe gaskets. Finally, I went to home depot and got a brass light switch place, dremeled out a hole the proper size, and bolted it in between the manifold and the downpipe. Its still there. My point is, if you have a gasket in that joint, perhaps its not up to the temperatures and is disintegrating. Something else to look at.

While cast iron welding is easy (do it myself), I also wouldn't recommend it. But, if you must, trot on down to your handy welding supply store, and get some 55ni Softweld rods, they are made for this job.

I do not think it's a lack of bracing that is causing the problem. Though bracing is normally a very good thing.

Don't know the engineered specifics of your application, and your description stays very unclear about what the problem actually is (do the studs break, pull out, just blow gaskets?). However, I would concur with others that it sounds most like mounting. Be it too soft or small studs, wrong nuts, wrong retainers.

Since it's a Flying Miata product, and Flying Miata has a pretty good reputation for working with their customers, I would likely be on the phone with them about this issue.

Sounds to me like you need a few things.

A) get rid of the flat gasket. Machine both flanges for a ring gasket Say 1/4 inch deep in both sides. Use copper ring aka thick wall pipe machined to fit.

B) use largest stud you can and use (15-20) bevel washer stack under the nut.

Both of theses mods would allow for some movement with out loss of the seal.

44Dwarf