ultraclyde said:

QCQD trailer hitches with universal joint coupling. Thank you Austrailia, now get us a US distributor.

The Treg hitch has been around for decades and seems more robust to me. Not sure I'd want to put pulling (axial?) loads on a U-joint.

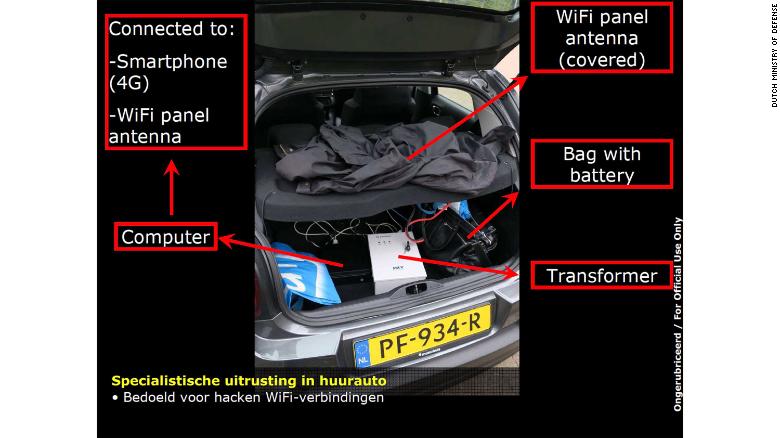

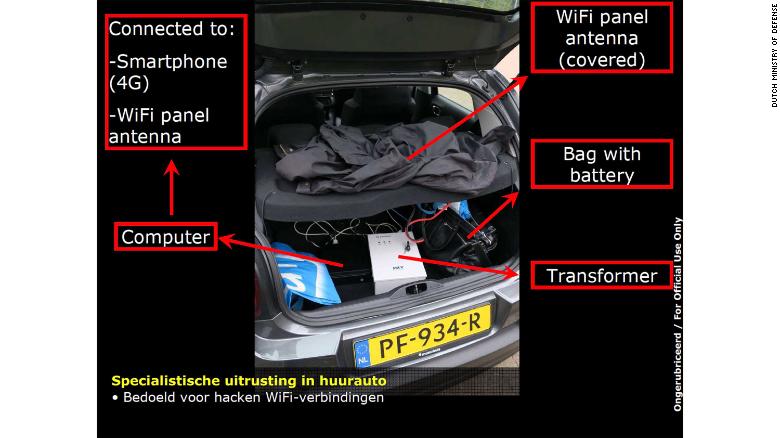

GRU wardriving setup...very nice.

edwardh80 said:

ultraclyde said:

QCQD trailer hitches with universal joint coupling. Thank you Austrailia, now get us a US distributor.

The Treg hitch has been around for decades and seems more robust to me. Not sure I'd want to put pulling (axial?) loads on a U-joint.

I'm not sure either of those solve a problem that actually exists for anything other than an extreme off-road trailer

lotusseven7 said:

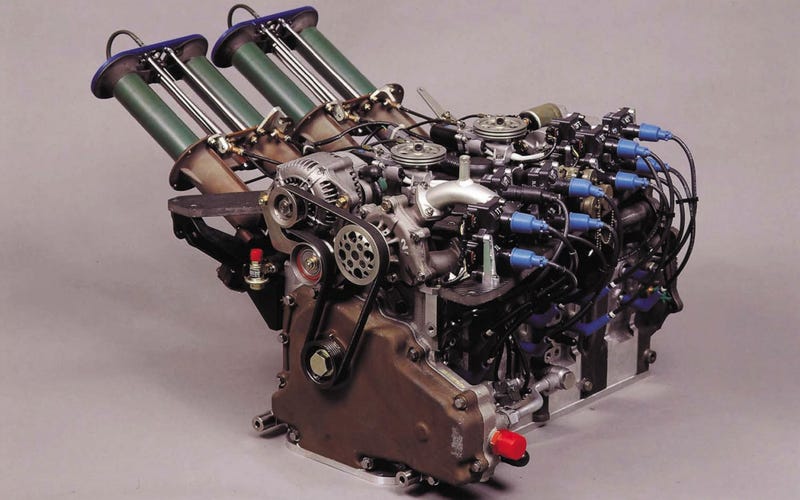

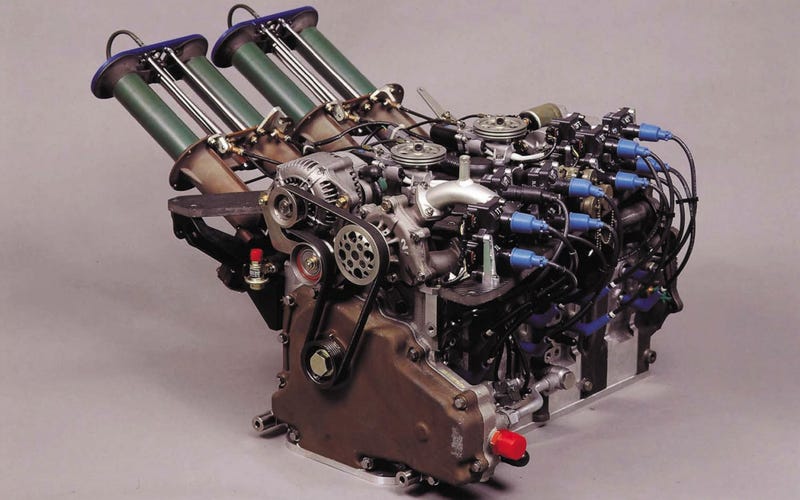

A perfect screensaver and piece of art whether standing still or at 200mph.

But why are those velocity stacks all caddywompus? Even if proven to work better I just couldn't live with it that way, and would actively boo the driver and team. Use a dang straight edge people. Man, I gotta stop looking at it or I'll lose sleep.

In reply to barefootskater :

To maximize peak efficiencies at different RPMs for each cylinder in order to get a broader power band.

Duke

MegaDork

10/4/18 4:18 p.m.

I believe it also has something to do with breaking up the vortex / low pressure zone right at the intake point. If they're all slightly different heights and orientations, they don't scavenge air from each other as badly.

Pic unrelated. Sorry about the tree:

Brian

MegaDork

10/4/18 4:50 p.m.

Something is out of place.

What could it be?

Mezzanine said:

In reply to barefootskater :

To maximize peak efficiencies at different RPMs for each cylinder in order to get a broader power band.

Now imagine that with engine management that could actually fuel each cylinder differently based on how it was filling at that instant...

Ever wonder whether a marginally-sized tennis ball has been sucked down the trumpet of one of those things during a forgetful start?

^variable splitting trumpets. Works better than telescoping trumpets which are just about impossible to seal properly, and the leaks kill performance.

In reply to Ransom :

Speaking of tennis balls in the stacks. I wish the B is for Build guys would put some balls in their stacks. It's driving me crazy - especially when they are welding and grinding 2ft away.

Sparkydog said:

In reply to Ransom :

Speaking of tennis balls in the stacks. I wish the B is for Build guys would put some balls in their stacks. It's driving me crazy - especially when they are welding and grinding 2ft away.

I have the exact same anxiety as you, and many more based on my experience building a tube frame car

Mezzanine said:

In reply to barefootskater :

To maximize peak efficiencies at different RPMs for each cylinder in order to get a broader power band.

Actually, it is because big block Chevrolets have stupid mis matched intake ports, due to the arrangement of head bolts- Six per cylinder..

As a result of this arrangement, each siamesed pair of intake runners features non-symmetrical left-hand and right-hand ports. The port on the right side of each pair (as you face the intake flange surface) is longer and directs the inlet charge more to the center of the chamber, and is referred to as the “good” port; the one of the left, obviously referred to as the “bad” port, dumps the air/fuel mix toward the cylinder wall and usually doesn’t flow as well as the right port. This minor idiosyncrasy of the big-block’s design has never been a real problem in terms of limiting the engine’s power potential, until extremely high airflow levels are reached on large-displacement or very-high-RPM engines

In reply to Duke :

If that’s in South Carolina I’ve stopped there.

Unrelated pics of my Dad’s Monte Carlos I came across today cleaning out my closet:

Chris from B is for Build must have heard us. In today's episode, he covered the velocity stacks on his V10 while working on the car

slantvaliant said:

The High and Mighty had the coolest tach ever.

Not a place you want to high side.

Streetwiseguy said:

Mezzanine said:

In reply to barefootskater :

To maximize peak efficiencies at different RPMs for each cylinder in order to get a broader power band.

Actually, it is because big block Chevrolets have stupid mis matched intake ports, due to the arrangement of head bolts- Six per cylinder..

As a result of this arrangement, each siamesed pair of intake runners features non-symmetrical left-hand and right-hand ports. The port on the right side of each pair (as you face the intake flange surface) is longer and directs the inlet charge more to the center of the chamber, and is referred to as the “good” port; the one of the left, obviously referred to as the “bad” port, dumps the air/fuel mix toward the cylinder wall and usually doesn’t flow as well as the right port. This minor idiosyncrasy of the big-block’s design has never been a real problem in terms of limiting the engine’s power potential, until extremely high airflow levels are reached on large-displacement or very-high-RPM engines

At least GM corrected the intake port spacing on the L18 8.1L, then killed off the BBC. Typical.

In reply to Duke :

Wow, that's quite a pair !

914Driver said:

Not a place you want to high side.

I need some context here. That's awesome.

In reply to The0retical :

That is the FIAT Lingotto building in Turin