I am looking to take a drafting class at the local community college and don't know which one to take as there are two different classes. One class is Solidworks and the other one is Computer Aided Drafting. The CAD class looks like it might be more challengine given it is UC transferable. I don't know the difference between CAD and solidworks or anything about drafting other than it is bitchin.

Which one would be more usefull to take? Any tips or suggestions?

Thanks folks!

Solidworks is nearly one of the defacto design "tools" out there. So think of it more as a technical class for that program then anything.

CAD is probably AutoCAD.

I wish they would offer pencil and paper drafting again. Get rid of the insane and can't be built designs designers dream up, "My computer says you can build it no problem.".

Duke

PowerDork

11/12/12 11:36 a.m.

Ranger50 wrote:

I wish they would offer pencil and paper drafting again. Get rid of the insane and can't be built designs designers dream up.

You've obviously not met some of the draftsmen I've known throughout my 25 years in the business... at least with a 3D computer model, you know that it could be built using the perfect materials and tools. On paper, it may not even match up in 3 dimensions.

Duke wrote:

Ranger50 wrote:

I wish they would offer pencil and paper drafting again. Get rid of the insane and can't be built designs designers dream up.

You've obviously not met some of the draftsmen I've known throughout my 25 years in the business... at least with a 3D computer model, you know that it could be built using the perfect materials and tools. On paper, it may not even match up in 3 dimensions.

This. The real solution is to make designers have a little machining experience.

I would guess that the CAD class either AutoCAD or the basics of CAD and the other class goes into Solidworks more in detail. Once you have learned one it is pretty easy to switch from one to another. I have used AutoCAD, Solidworks, SolidEdge, NX and Inventor.

RossD

UberDork

11/12/12 11:41 a.m.

Here are my thoughts: AutoCAD (which will be supersceded by Revit) is for the design of buildings and their mechanical/electrical/... systems. (I.E. buildings, plants, campus wide systems,...)

Solidworks is for designing machines and highly engineered systems. (i.e. Designing a paper machine, gearbox, manifolds,...)

Duke

PowerDork

11/12/12 11:47 a.m.

RossD wrote:

Here are my thoughts: AutoCAD (which will be supersceded by Revit) is for the design of buildings and their mechanical/electrical/... systems. (I.E. buildings, plants, campus wide systems,...)

Solidworks is for designing machines and highly engineered systems. (i.e. Designing a paper machine, gearbox, manifolds,...)

This is correct, pretty much on all counts. However, as someone who uses both AutoCAD and Revit, I'll say it's going to be quite a while before AutoCAD disappears.

So AutoCAD is more about systems planning, imaging, engineering and solidworks is about basic 3D shape and design so it sounds like solidworks would be more useful to me as I'm no engineer.

Perhaps I should describe my goals for the class a bit. I am looking to be able to design parts for my bike and car.

I have a few days before registration so any more insight is appreciated.

Thanks for the help and suggestions, I always admired engineers. When I was in school I used to hang out at the on campus bar and have a beer while writting up lab reports and there would be the engineering guys talking about their difficult classes and how you had to pass a class with good marks to proceed through the rigamorale. Basically if you screwed up one class you would be a year behind.

RossD

UberDork

11/12/12 12:24 p.m.

Engineers use both. Drafters/Designers use both. But if you want to design mechanical brakets or machine parts, I'd go for Solidworks or a similar software package. Although, I haven't used Solidworks in a professional manner...just AutoCAD and Revit.

Engineering student protip: Learn autocad FIRST. Its a horrible program, but you need to know it, and if you learn in a good 3D environment first(Inventor, Solidworks, Catia, etc.), you can not transfer any of those skills to autocad's craptastic, command line based, 2D environment.

I did it the hard way, becoming fairly fluent in Inventor in high school, then taking Autocad in college. Made what would have been an ok class the worst class ever.

Ian F

PowerDork

11/12/12 12:45 p.m.

Duke wrote:

This is correct, pretty much on all counts. However, as someone who uses both AutoCAD and Revit, I'll say it's going to be quite a while before AutoCAD disappears.

Yeah... I'd like to use Revit more, but for small projects with limited architectural changes (most of what I do), doing projects in Revit is just too time consuming.

If you are doing this soley for personal use, look into the actual costs of the programs. From what I remember, SolidWorks is not a cheap program to buy, although if you take the class you may be able to get a student discount. Ditto for ACAD, but in general, basic ACAD will transfer to cheaper CAD drafting programs.

I'm glad to hear SOMEBODY is taking AutoCAD in college... I can't tell you how many engineers we've hired over the years fresh out of college and had to teach them how to use CAD...

CAD is computer aided design, and refers to the genre in general. Solidworks is a brand of CAD software. So it AutoCAD. But autocad isn't good at 3D modelling, so if that's what you want, you may want to take the Solidworks course.

My suggestion would be to carefully study the industry you want to use it in before taking a class. In my industry ProE is what is used almost exclusively. It's different in other industries, so you need to know what is the most common type used.

If you are just doing it for your own benefit, Solidworks is easier to learn to use than ProE, but isn't as powerful. And then there are all the other 3D solid modelling software packages out there.

My Dad started as a draftsman in the mid 1950's for Grinnell Fire Protection and just finished his career in 2010 by drawing up his last design. They called him a "Design Engineer" but he never went to college nor to the sadness of my grade school buddies did he ever "drive" a train..

I stopped in to see him sometimes and he was in an engineering office with 2 "kids" drawing designs on computers and him sitting drawing on a drafting board. I can still recognize his printing when he mails me something as he follows the lettering he learned back in 1955.

I learned mechanical drawing in high school in the late 70s.

I went to art school where the foundation is figure drawing, and I studied illustration.

I learned AutoCAD from a great mechanical designer around 2000.

I switched to SolidWorks in 2004 and have been a daily user since then.

The key to designing with manufacturability in SW is ~understanding how things are made~ and modeling that. If you've spent decades using materials and tools to produce physical things...

You'll be fine.

I work with freshly minted engineers and mechanical designers most of the time. What I see is an absence of a "mechanical vocabulary" - I have through experience learned how strong things need to be, what to make them from, how and where to fasten and with what.

I was recently given a bracket that was no longer used on a robotic high-throughput screen work cell where I work.

It's made of 3/4" stainless steel plate. Actually, it's not 3/4" plate. It's been faced on both sides to .750 +.001, -.001. The designer could have noted "3/4" 304 stock" and reduced the cost. Anyway, the big side of the bracket is about 6"x16", the small side 6"x6". It has a triangular web to add stiffness, and it's fully fillet welded, then final machined to hold some amazingly tight angular tolerance.

It's easily capable of supporting maybe 4 tons.

What it was specifically designed for was to hold a wellplate stacker that weighs about 100 pounds. I imagine it cost several thousand dollars at minimum, and the task could have been accomplished with $100 worth of 80/20 extrusion from McMaster-Carr.

This is the problem.

IMO, if you are starting cold, you want to make sure you take a class that actually teaches you drafting. Descriptive geometry, how to project views, GD&T, tolerance stacks, etc. After that, you can take a class in whatever software. If you already know what you want to do, it becomes much easier to learn which buttons to click in whichever software to make that happen, because they are all pretty similar in a lot of ways.

By way of resume, I've been in drafting/CAD for 25 or so years. Started on the board, then AutoCAD 9 through 12, PDGS, Pro/E, I-DEAS, Catia V5, and now NX.

OK I'll grab a drafting book and start reading about the fundamentals before taking the class which doesn't start until january. I hate the semester system also, classes go on on on and on, then you get 4 more weeks.

Thanks for all the tips and suggestions!

You might want to do a search for Turbocad. Its an ACAD knock off that works really well and has very good tutorials. They have or had at least a free download that is a fully featured but out of date version of the latest software they sell.

They have a very good help forum where some pretty smart people don't mind helping newbies. It is also completely compatible with ACAD.

I taught myself and I can turn out some pretty good stuff now. (After 5 years)

Its Turbocad LE. (learning edition) You will have to go looking for it.

motomoron wrote:

It's made of 3/4" stainless steel plate. Actually, it's not 3/4" plate. It's been faced on both sides to .750 +.001, -.001. The designer could have noted "3/4" 304 stock" and reduced the cost. Anyway, the big side of the bracket is about 6"x16", the small side 6"x6". It has a triangular web to add stiffness, and it's fully fillet welded, then final machined to hold some amazingly tight angular tolerance.

It's easily capable of supporting maybe 4 tons.

What it was specifically designed for was to hold a wellplate stacker that weighs about 100 pounds. I imagine it cost several thousand dollars at minimum, and the task could have been accomplished with $100 worth of 80/20 extrusion from McMaster-Carr.

This is the problem.

Amen brother.

Also just because you can do it in the computer does not mean I as the end user, me, is not going to tell you where to show it when you hand me something like this and the cost associated with it.

drafting... it is bitchin

I'm surprised pen and paper isn't a prerequisite but maybe that's a dinosaur. Drafting is one of the best tools in the 'ol toolbox.

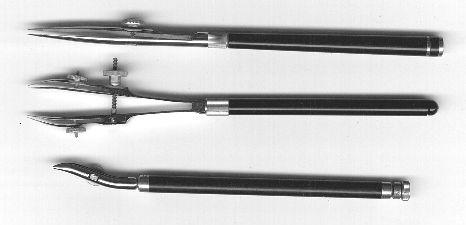

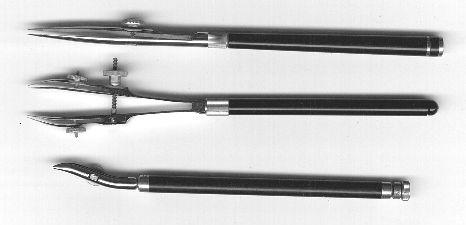

Crap. My drafting and architecture clases all featured these:

I still have them around here somewhere, including a compass which was a royal PITA to operate.

motomoron wrote:

I work with freshly minted engineers and mechanical designers most of the time. What I see is an absence of a "mechanical vocabulary" - I have through experience learned how strong things need to be, what to make them from, how and where to fasten and with what.

I was recently given a bracket that was no longer used on a robotic high-throughput screen work cell where I work.

It's made of 3/4" stainless steel plate. Actually, it's not 3/4" plate. It's been faced on both sides to .750 +.001, -.001. The designer could have noted "3/4" 304 stock" and reduced the cost. Anyway, the big side of the bracket is about 6"x16", the small side 6"x6". It has a triangular web to add stiffness, and it's fully fillet welded, then final machined to hold some amazingly tight angular tolerance.

It's easily capable of supporting maybe 4 tons.

What it was specifically designed for was to hold a wellplate stacker that weighs about 100 pounds. I imagine it cost several thousand dollars at minimum, and the task could have been accomplished with $100 worth of 80/20 extrusion from McMaster-Carr.

This is the problem.

Bahaha I have seen that so many times and I only graduated a year ago. People wanting to jack off for the sake of jacking off. Example in college I worked on a human powered off road vehicle that ended up costing a bit over $20k partly cause the team lead decided to build an entirely CF leaf spring which also functioning as the lower control arm. He didn't bother to consider roll centers or camber change or anything. So we ended up with roll centers ~20 inches below the ground when the CG was about 15 inches above the ground. Needless to say it spent most of its time trying to throw riders out of it. Velcro as seatbelts didn't help much either.

Hal

Dork

11/12/12 8:14 p.m.

motomoron wrote: What it was specifically designed for was to hold a wellplate stacker that weighs about 100 pounds. I imagine it cost several thousand dollars at minimum, and the task could have been accomplished with $100 worth of 80/20 extrusion from McMaster-Carr.

Thanks for the laughs and memories. My father's work was taking designs the designers/engineers came up with and figuring out how to manufacture the parts. He frequently had some sarcastic comments about the designs.

But the one I remember was when he was given the drawings for a new rather simple part. He went to the local hardware store that night and the next morning put a handful of the parts on the bosses desk and told him he could get all they needed for 20 cents each.