If you re-ring the motor, you won't really hurt any parts that you'd want to keep anyway. Having said that, I would hone as little as possible anyway. Get those rings too far out into the bores and you'll beat the hell out of the ring grooves in the pistons. That'll lead to a lot of smoke, a busted ring, and a good sum of money changing hands.

I did hone 2 and 3 as little as possible, but it was still a considerable amount. There's a pretty good chance that this bottom end won't end up in the 128. If it smokes excessively or is down on power, I will just source a junkyard 1500 from a Strada or X and swap the Yugo head on (unless I find a FI 1500 for a reasonable price). There's a low mileage carbed strada 1500 in a warehouse about 10 miles from my house. It is supposedly a low mileage unit (~60k), but they want $400 for it. It's been in their inventory for 8(!) years. I told them I would be interested in it if they came down in price a bit, because after sitting that long in a surprisingly damp building it would have a big question mark on it to me.

In related news, the rings are supposed to be here tomorrow. Hopefully I can get one or four of the pistons fitted back into the bores before the weekend.

At some point I will tear down the head that came on the car and see if it can be salvaged with a little lapping. I still have no idea what fate the Yugo will meet once I tear it's heart out. There's definitely some stuff living where the B-Series would go and I still really, really want and Exxie.

I've been really busy and haven't had a chance to update since Friday. So, here's a cliff note update:

Friday evening: Hand filed all of the rings. Factory spec is .012" to .016". I fit all of them on the tighter side of the spec, most ending up at .012" or .013". I don't have any way to accurately measure the bore, so I just test fit the rings in every possible orientation and position and measured the end gap. This absolutely took ages. Cylinder three has about a .002 taper at the top, so I fit the rings I hair on the tight side (.011") at the bottom to try and compensate. This very well could bite me in the ass, but....

Saturday: I cleaned, and cleaned, and cleaned. Then probably cleaned some more. Then placed the rings on the pistons as per the ring manufacturers specifications. Then cleaned a little more. Then installed a piston, rod, and bearing. Then cleaned a little more. Then rinsed. Then repeated. And quite possibly cleaned some more. It is amazingly difficult to keep things sanitary when doing the "berkeley pulling the engine, I'll just do it in the car".

Cylinder 4 looks like crap in this photo and I have no idea why. It doesn't look like that in person. Maybe just E36 M3e lighting bringing out the imperfections? Whatever, it's already together.

Anyways. We officially have a rotating assembly and boy does it rotate! Nice and smooth, no hangups or tight spots.

The rest of the parts should arrive tomorrow. Well, everything except the timing belt because I still have no idea which one I need and I keep forgetting to look into it. I need to compare the one on the 128 against the one off the Yugo to see if the tooth shape is indeed different. The "tensioner" setup is a joke on this car. You can kind of see it in the photo above. It's just a bearing on a stud, but the bearing's ID is bigger that the stud, so it's on a bronze bushing, but the bushing isn't tight on the stud OR the bearing, so the whole shebang is just kinda floppy, which is probably OK because there's no adjustment anyways...

Holy crap, I take a break from this thread for a week and it becomes even more awesome.

I can't believe how clean that shell is.

I don't think you should go buy out the Fiat hoarder's entire inventory; it's a better idea to buy that stuff in instalments. Note that there's a thread about the dropping value of scrap.

This thing has been kicking my ass. Lots of 1 step forward, 2 steps back kind of nights at Vault 6. I'll give you guys a full run down a little later on, but I wanted to let yous know that I'm still tooling away and am finally making some progress.

The head is all cleaned up and is ready to get slapped back on.

So, half of the headbolts on the Fiat SOHC motors are partially obscured by the cam tower. Jon, the previous owner of the 128, was nice enough to lend me the factory tool, plus a homemade jobber. Unfortunately, both of his tools were for bolts with a 19mm head, and mine are all 17mm.

So, I had to make my own hurried little version with a 17mm wrench and an unloved 1/2" drive socket.

Version 2.0 will be a little less spur of the moment...

So, with the above diagram and my bentwrench, I was able to spin the 10 headbolts up to 29ft/lbs before going whole hog at 69ft/lbs.

I'm going to try to make a big push and get it all buttoned up tonight, as it is Shop Night. But we are also screening Empire Strikes Back in the shop tonight, so I might just drink beer and watch the idiot box.

Oh! The timing belt that came off is a 136RHP150. So I need to do a little internet research and see what exactly that is.

Burrito wrote: The "tensioner" setup is a joke on this car. You can kind of see it in the photo above. It's just a bearing on a stud, but the bearing's ID is bigger that the stud, so it's on a bronze bushing, but the bushing isn't tight on the stud OR the bearing, so the whole shebang is just kinda floppy, which is probably OK because there's no adjustment anyways...

Yeah, that sounds super wrong. I was under the impression all were tensioned the same way, just with a different bearing on the tensioner, and none had a setup that screwy for sure.

OK. According to Chris Obert, a Dayco 136RHP150 is for a fuel injected Yugo. Perfect.

According to this eBay ad, it was also used on a lot of small block VWs that we didn't get in the states. But, it also tells me what every other manufacturers part number is.

That Spanish eBay ad said:

BOSCH

1987949168

9168

F000KR9270

CONTITECH

CT846

DAYCO

135STP190H

80 21787 52654 7

GATES

5427

5427XS

INA

5360204000

IVECO

VT294

LEMFÖRDER

1461001

1461002

617060227

MOPROD

MTB371

OPTIBELT

HR90135X19

QUINTON HAZELL

QTB425

ROULUNDS RUBBER

135ST190

135ST190R

SEAT

030109119H

030109119M

030109119S

TRW

4833927

UNIPART

GTB1427

UNIROYAL

90135X19MM

VAG

030109119H

030109119M

030109119S

VW

030109119AB

030109119AG

030109119G

030109119H

030109119M

030109119S

Sorry about the formatting. Tell me how to fix it?

So, now I just need to weed through that list a little bit and see what belt I can get in the states for anything that isn't $60 in Chris Obert's pocket.

Kenny_McCormic wrote:

Burrito wrote: The "tensioner" setup is a joke on this car. You can kind of see it in the photo above. It's just a bearing on a stud, but the bearing's ID is bigger that the stud, so it's on a bronze bushing, but the bushing isn't tight on the stud OR the bearing, so the whole shebang is just kinda floppy, which is probably OK because there's no adjustment anyways...

Yeah, that sounds super wrong. I was under the impression all were tensioned the same way, and none had a setup that screwy for sure.

Yeah, it's something the PO did. The issue is it's a 1300 "shortblock" belt on a 1500 "tallblock". I'm guessing it wasn't quite long enough to be used in conjunction with the factory tensioner.

My immediate plan is to grab a watercooled VW timing belt tensioner and scab it on. The stud is the same size, so apart from spacing, it should work swimmingly.

Belt http://www.amazon.com/5427XS-Gates-Timing-Belt-Volkswagen/dp/B00L5HTOKY

I think the proper way to do this would be to grab the pulleys off a 1500 EFI motor and use the 1500 belt and tensioner bearing. Though if you can make it work (proper belt tension) with probably more common VW parts I don't see a problem there.

Disregard (almost) everything I said about timing belts above. I don't know how I ended up on that Spanish eBay listing, but that's not the correct belt. JTHW8 pointed me towards yugoparts.com, and the fact that they list the proper EFI belt. ~$40 shipped to my door is not the deal of the century, but I'll take it. I know that the Dayco 136RHP150 that came off the car is specifically for an EFI Yugo, so I know that my pulleys are from the stock Yugo 1300.

The next hurdle is tensioner. I think I have a Rabbit timing belt tensioner in a box in the loft, but if not they can be sourced anywhere for about $15. I will probably string the motor up with the old belt as a mock-up and see if I need to modify anything or look for an alternative tensioner donor/source.

Who's got two thumbs and put the headgasket on upside down?

This guy!

Burrito wrote:

Who's got two thumbs and put the headgasket on upside down?

This guy!

Tell us how you caught that error! I'm guessing there is an overheating story or something like one...unless there was some visual indicator like part of the gasket sticking out in one place?

Kenny pretty much got it, yeah. I somehow decided that the gasket was symmetrical and that the red line would face the head, like every other head gasket ever. I know I flipped it over multiple times before decided which way it went, but I can be something of an fool at times and missed a rather apparent difference.

Top center. That little copper ring. That's very much not centered. At least it doesn't say "This side up, Dummy" (on either side...). I think it is a fairly honest mistake and is probably mostly due to complacency.

Luckily it was caught very early in the night. We got the oil pump and pan reinstalled before dumping in some cheap oil. I used the old 128 points distributor and a drill motor to prime the oil system and get some oil moving through the engine when, much to my surprise, oil came spewing out from under the head between cylinders 2 and 3.

I was a little upset with myself at first, but DaveBob told me to take a few minutes and find a fresh beer. Then we yarded the head back off, cleaned the gasket and both mating surfaces, and torqued her back up. Technically we did make some progress last night and it is slightly further along.

Yes, I reused the gasket. No, I'm not ashamed (ok, I'm a little ashamed). It'll either work, or it won't, right? At this point I just want to hear this motor run. I still don't know if every ancillary is junk, if the ECU is fried, etc. and I'm staring at a money pit. I'm almost a month into what was supposed to be a 2 day project, not to mention it's cost me twice what I thought it would...

I'm about a mile up Ain't Care Creek and, if I'm completely honest, I'm taking on some water.

I know head gaskets are, as Jumper K Balls put it so well, like condoms in terms of the usage count, but is it a crush/form thing, or a heat-set/cycle thing? Crossing my fingers that you prove it's the latter...

It is a crush thing. Head gaskets are very different thicknesses before and after installation. By at least 0.010.

Although on this motor I would probably try and reuse it myself. It will either leak or not.

tuna55

MegaDork

10/23/15 7:21 p.m.

I've done stuff like that.

My worst: I assembled the transmission gears on the mainshaft, including some very inventive ways of dealing with super snap rings, and then looked at the speedo gear (goes first) on the bench afterwards.

These are pretty crude engines, it might work.

Would have been bad news if he didn't prime it first, that hole is the one that feeds the cam and lifters.

Bring out yer dead or Hurtin' for a Squirtin'

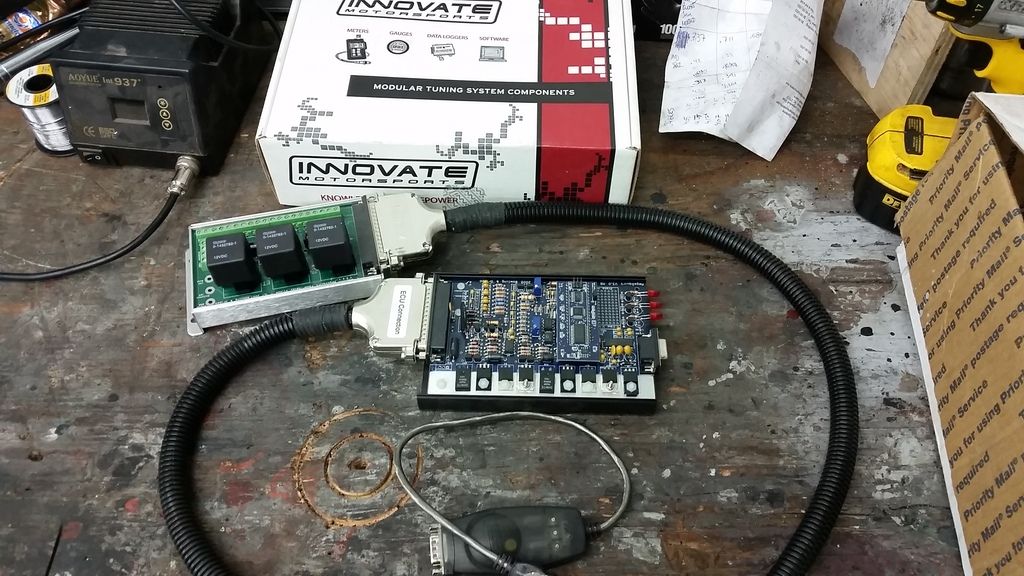

After 3 days of troubleshooting and futzing about, I'm ready to declare the ECU deceased.

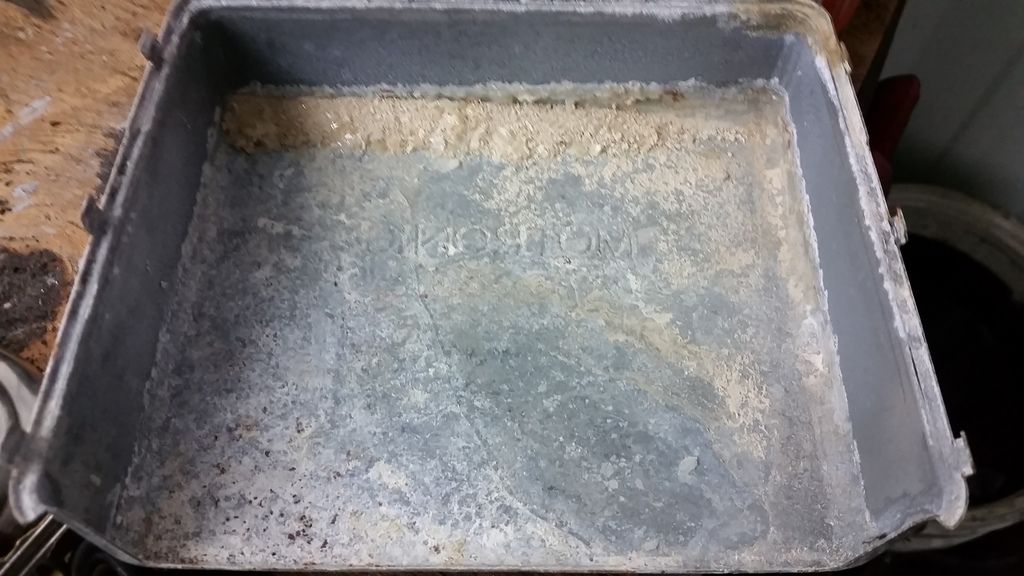

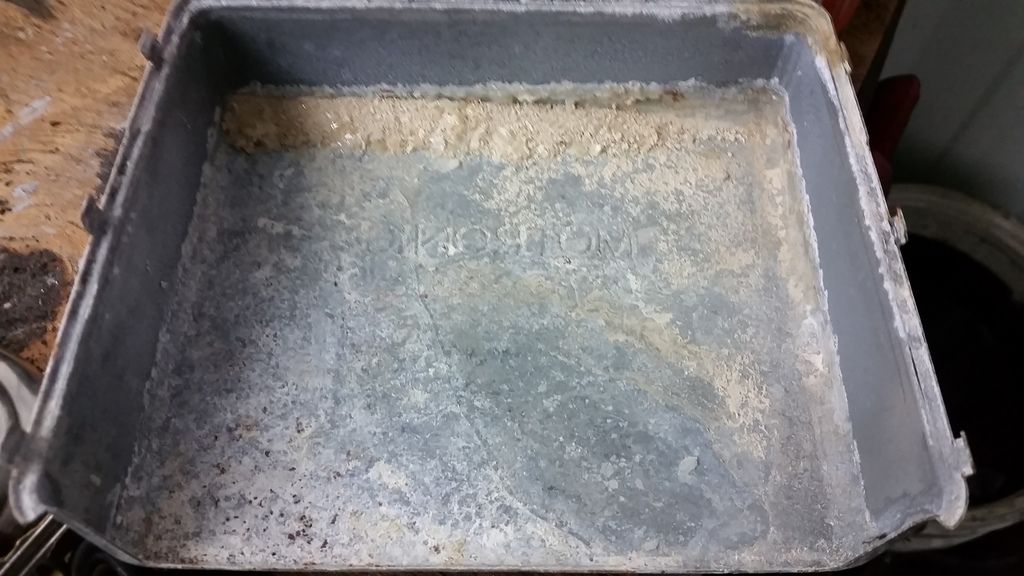

The inside of the Motronic box shows a history of water damage...

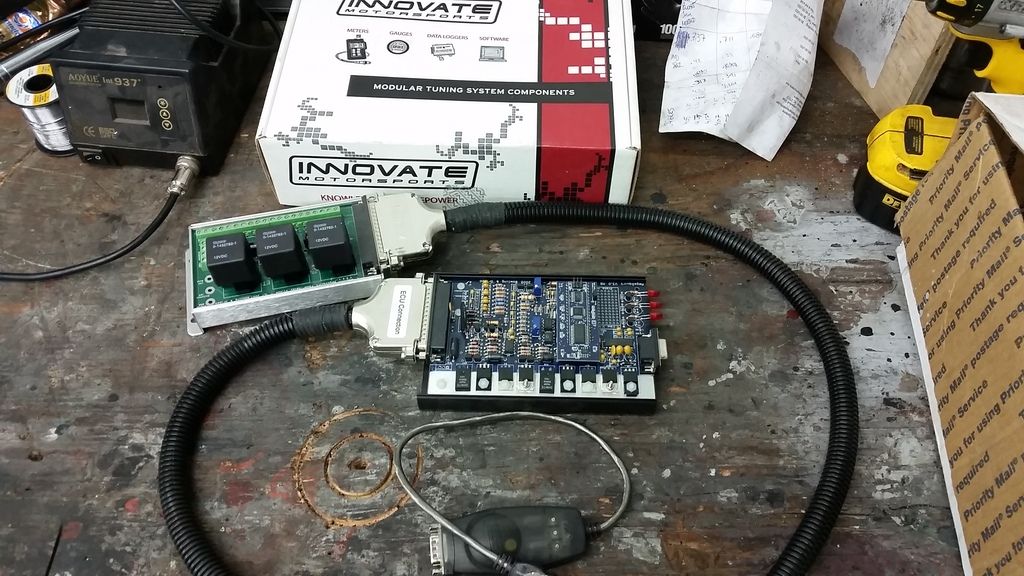

And, while the circuit board itself doesn't show too much water damage, it reeks of magic smoke and germanium. Not to mention some crispy looking components.

I tried to reflow all of the damaged solder connections, but since it's almost all surface mount componentry, this was really just an exercise in futility.

So. What now? 4 options, as I see it.

-

Part it out. Take what I need for the 128 and get this Turd out of my way.

-

Axe the FI junk and toss a carb on it. This defeats the entire purpose of seeking out a FI Yugo, apart from the 5 speed aspect.

-

Find another hens tooth ECU. There's possibly one in PA, and one on eBay in Serbia...

-

Megasquirt. I have, quite literally, almost everything I would need to do this. Technically all these goodies belong to the 850 Coupe project, but if I'm completely honest, it ain't going anywhere any time soon.

At this point, I'm honestly not sure what I'm going to do. I'm going to take a day or two off, clean up the shop, and read up on MS a little bit. I need to look into how I configured the board when I built it and what I would need to do to make it work for this install. If I go the MS route, it will be fuel only for ease of install and to save some money.

Megasquirt the Yugo. You know, for science.

JoeTR6

Reader

10/27/15 3:23 p.m.

Squirt it. More reliable (and replaceable) in the long run than a 25 year old ECU. It's more work, but the car will be better for it.

Though I'm sure you're practically married to it and Mrs is more appropriate, MS Yugo has a nice ring to it.

Back to the timing belt tensioner for just a moment. That motor should have one tensioner mounted on a plate with a spring.

In reply to Jerry From LA:

The problem is he's got a tall deck block set up for the short deck efi Yugo belt (to make the factory EFI work), presumably this runs the stock tensioner out of travel. If we're ditching the Yugo EFI, using the late EFI 1500 parts (pulleys, belt, tensioner bearing) is probably the best course of action assuming the cam pulley is interchangeable.

In reply to Kenny_McCormic and Jerry From LA:

Yep. I still need to pick up a VW tensioner to see if that will work. The new belt won't get here until Friday, so I'm not in a huge hurry.

As far as I know all of the pulleys are interchangeable. I did read something about the accessory drive stuff on the FI Yugo having a different offset than any of the 128/Strada/X19 stuff, though. Jon, the guy I got the 128 from, has a pile of 1100cc SOHCs that he said I'm welcome to. I might grab a pile of pulleys and an alternator or two for experiments down the road. Not much sense in doing it right away since I just dropped $40 on a very specific T-Belt.