RIP little Spider. But the Coupe is going to be twice as amazing in its stead.

Wednesday is dude's night. My buddy David usually comes by the shop to shoot the E36 M3, throw darts, drink a few beers, and, lastly/leastly, work on cars. Sometimes we get a lot done; sometimes we get a lot drunk.

Tonight was a good middle of the road sort of evening. I started off strong with about 15 trips up to the loft with arm loads of Spider parts. I transitioned into broom pushing and shop-vac-ing until David arrived.

We did a little of this:

But mostly we did this:

We actually got a fair amount done, I just didn't take any pictures. The driver's rocker is pretty close to going back in. I'll see about grabbing some photos of tonights work tomorrow, but my schedule is looking a little tight.

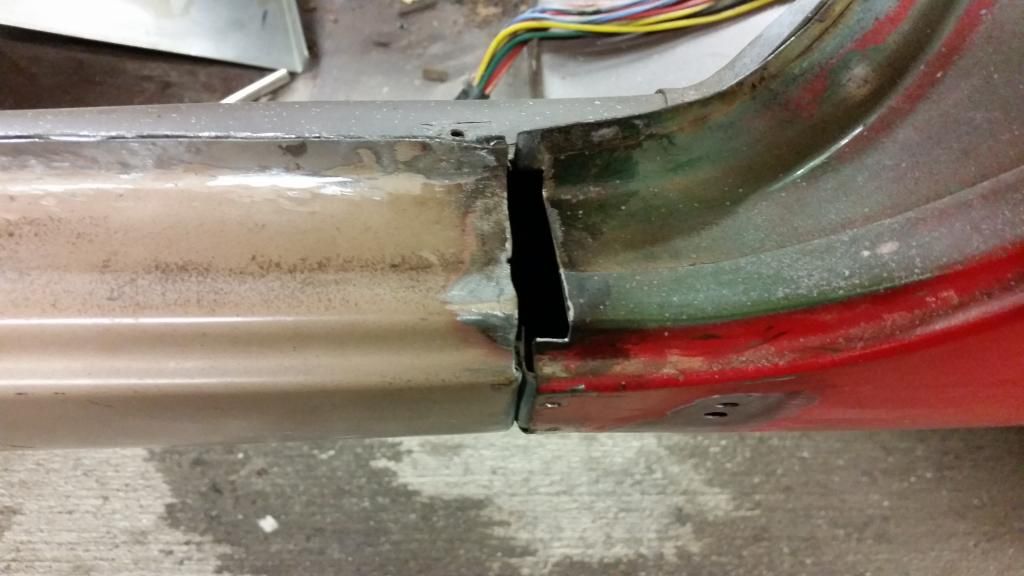

So, here's where we left off one the front of the driver's rocker.

Better than it was, but still a fair amount of dead space. I chopped off the piece I spot welded on underneath and moved it to the vehicle side.

Made and tacked in a patch.

And welded.

And ground out.

It'll need a little hammer and dolly work to be totally flat, but overall I'm happy with it.

More photos to come, but I'm out of time for now.

Part 2.

The existing flange on the body side of the rear rocker area was largely rusted through. I decided that the best way to properly locate everything was to cut the existing flange off, use my handy shrinker/stretcher to form a new piece.

Then I tossed a couple three tek screws in from the outside to pull it up flush to the other panel.

Dinner break update.

Filled in the holes on the inner sill this afternoon.

Before:

After:

I'll trim the lower flange off flush with the rest of the sill before attaching the outer rocker.

I also ground out and filled in all the pin holes along the bottom of the sill.

Hoping to head back down later this evening.

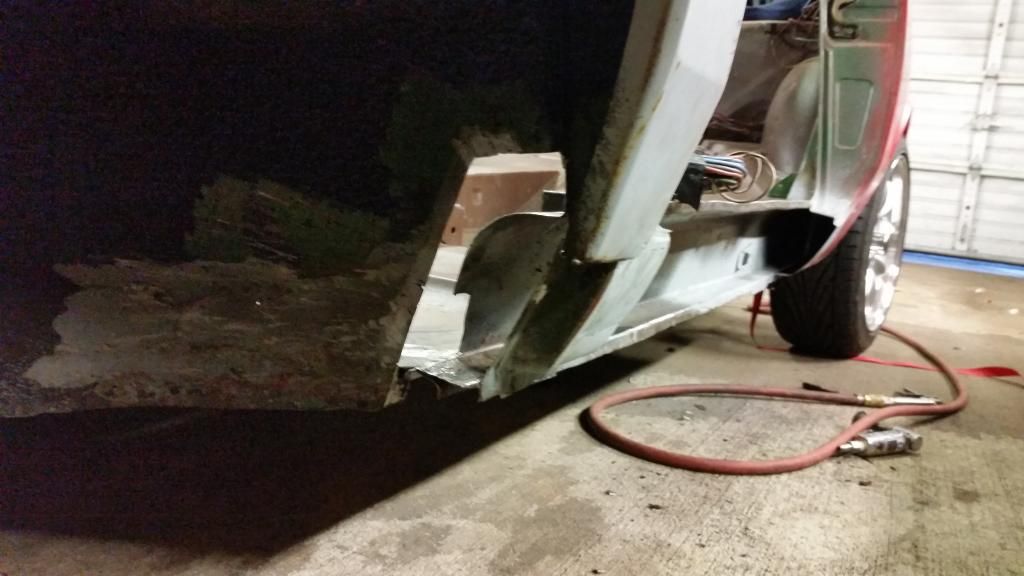

Last night after dinner I worked on the rear portion of the sill.

Here's what I was left with after removing the previous owners work. Short, porous, and berkeleyed.

Removes the infected steel.

Offered up a quick patch. It's misaligned here, I know, I fixed it but didn't bother taking another photo before welding.

The "welding spoon" (it's a piece of copper pipe I crushed in a vice...) is there to keep weld from extending above the two flanges.

The "welding spoon" (it's a piece of copper pipe I crushed in a vice...) is there to keep weld from extending above the two flanges.

Welded, lanished, and zinc'd.

Second layer.

All trimmed back with the rocker in situ.

Pretty much good enough. That's all hidden by the door when it's shut, so I'm not super worried about it. It will get a short extension put on underneath exactly like I did on the front of the rocker so I have a positive way to locate that portion.

That's where I ran out of shielding gas, on a Sunday no less. Bummer.

So, what's a guy to do but cut more rot out of his car?

Taking tomorrow off, so I'm hoping I can push to get the rocker and the rot I cut out today all patched up and finished. After that we will turn the car around and do it all again on the passenger side. After that we will flip the car over and do it on the bottom.

Ain't Fiats grand?

Awesome work buddy! I have felt your pain. But it's a great feeling when you have the confidence to form patches and fix those rust holes the right way. Keep cutting and welding!

Not as productive of a day as I thought it would be, but who's counting anyways. Quality over quantity, right?

Bent a piece up in the brake then shrank and stretched till I had this.

Then trimmed it's profile until it was flush on both top and bottom.

Made up a template for piece #2.

Transfered that to steel, cut it out and stitched it to the other half.

After a little bit of fiddling it's ready to be blasted in (apart from the obvious grinding).

I was exited about the little engine gettin BOOST, now im looking forward to seeing how the body work turns out, you seem to be pretty skilled at metal work.

This is why I haven't learned to weld yet; I'd immediately pick up something like this to save.

Looking great! I love the coupe.

Thanks for the kind words and encouragement, guys. A little positive reinforcement goes a long ways with me and it's always nice to know that someone is enjoying these posts.

I really like those little magnets you're using to hold the patches in place for welding. They are so much smaller than the ginormous magnetic triangles I have from Harbor Freight. Where did you pick those up?

Love to see your attention to detail on the fit up. Awesome work. Keep it up!

I buy the rare earth magnets in packs of ten from Princess Auto. I have been using them for long enough that they seem to show up all over my shop! Very handy.

In reply to mblommel:

NOHOME hit it square on the head. I think I got them at Home Depot, though. I had about 12 of them to start, I think two remain at this time. Probably about time for another pack.

I do quite a bit of fabricating at work. And since it's a production facility, I don't always get to take my time and do things the way I want. My old man is one of those "If you're not going to do it right, don't berkeleying do it at all" kind of curmudgeonly, aging old-world machinists. I guess it made something of an impression on me. It's gotten to the point where I am relaxed by making a part fit just so, or having it come out exactly as I pictured. Like a really E36 M3ty Italian Zen Garden.

Plus, welding under the car blows. Anything that I can do to make it go faster and easier, I'm happy to do.

Should be heading to the shop here in a while. Perhaps I will have an update this evening.

Burrito Enthusiast wrote: Like a really E36 M3ty Italian Zen Garden.

Quote of the day!

Lovely work, as usual. I always enjoy the updates...

Curious.

I am sure you are aware of hammer-forms. And while I love me some shrinker- stretcher metal-shaping, I would have gone with a hammer-form just to save that weld. Your thought process?

To those that say they want to learn to weld tin, pay attention to this weld bead. Looks like the trigger was pulled 59 times to do the job. This is what it should look like pretty much on both sides.

Liking this thread a lot.

NOHOME wrote: Curious. I am sure you are aware of hammer-forms. And while I love me some shrinker- stretcher metal-shaping, I would have gone with a hammer-form just to save that weld. Your thought process?

Uhh, I got a new tool and I wanted to play with it. I honestly didn't even think about hammer forming it.

I'm also pretty green when it comes to sheet metal work, so any time I can weld fresh steel in a comfortable position it's a win-win. I figure shielding gas and wire is cheap enough to take the long way round for the sake of practice on occasion.

I got a few hours to dork around in the shop today. I'm coming down with something of a cold, so I don't know how productive I'll be over the next few days.

Not 100% happy with it, but it's good enough for who's it for. Welds started out a little cold, so I turned up the heat a hair and proceeded to burn a bunch of holes in the panel. Lesson learned there.

Anybody want some Fiat?

"...Pretty new when it comes to sheet metal work"?

Fooled me! You move around challenges like you have been doing this for a while. You seem to enjoy what most would call an ordeal. Carry on...

NOHOME wrote: "...Pretty new when it comes to sheet metal work"? Fooled me! You move around challenges like you have been doing this for a while. You seem to enjoy what most would call an ordeal. Carry on...

I've read a LOT of build threads. I'd rather scroll through a TonyBMW thread on Retro Rides than watch the idiot box any day of the week. Information is everywhere, it just needs absorbing.

I say it's all practice. Work is practice for the Scirocco, Scirocco is practice for the Fiat, the Fiat is practice for the Alfa, etc.

I'm still on the honeymoon with this car. I've been building it in my head for the last five years, so I'm happy whenever I get to do anything on it right now. It'll be an ordeal before too long. ![]()

That being said, I hope things speed up before too long. We're supposed to drive this car away from our wedding on July 18th 2015...

Hope my friends like pushing! ![]()

You'll need to log in to post.