Challenge budget so far:

previous challenge budget: 868.78

recoup total: 800

new money:

added core charges back in per the new challenge rules

given 4 unknown rate red coilover springs

purchased coilover sleeve kit for honda civic: 43.99

sold 2 red and 2 civic springs: 22

purchased 4 used bilstein: 40

purchased entire drivers rear suspension 40

purchased passengers fender: 40

purchased inner fenders: 20

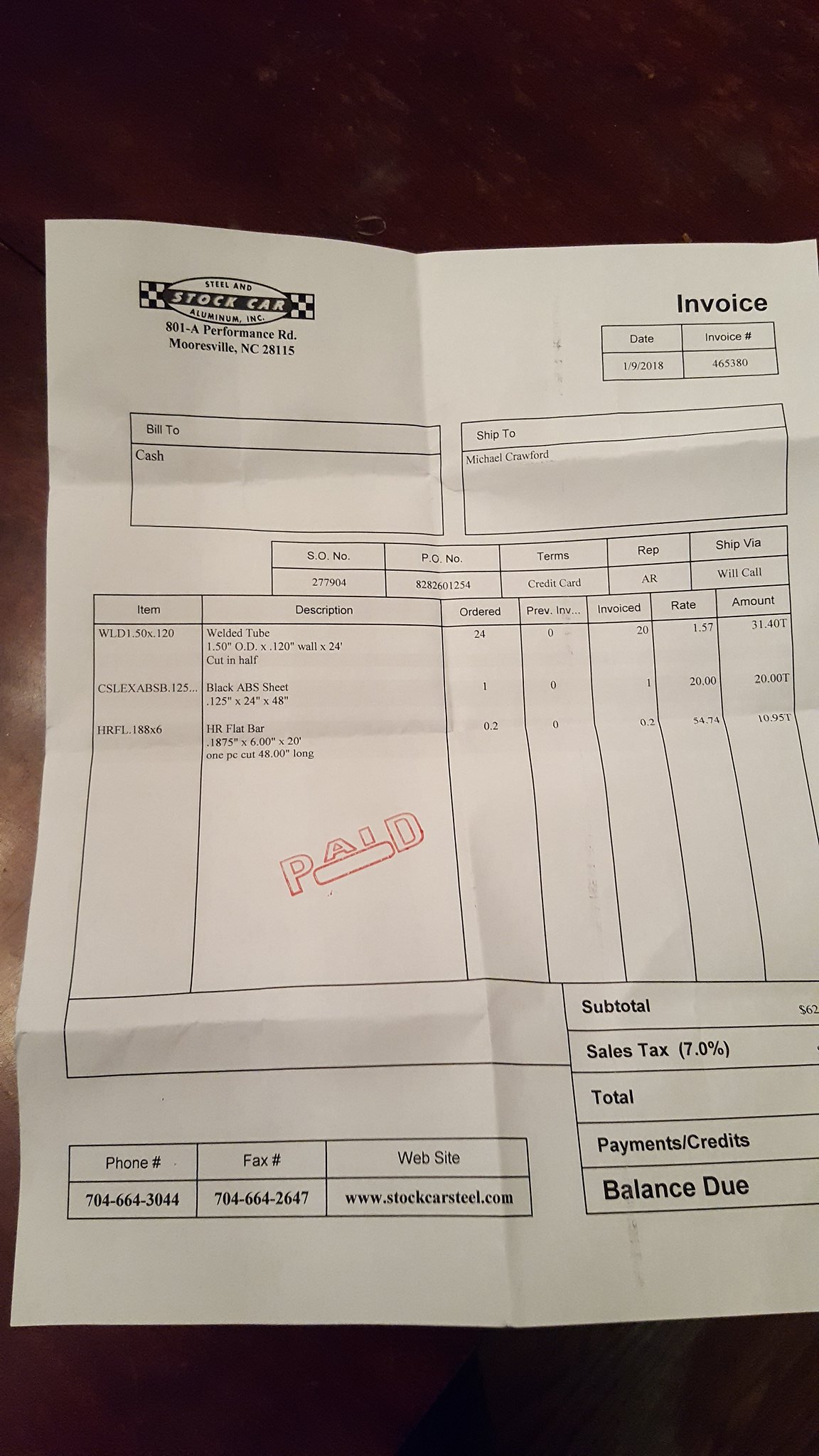

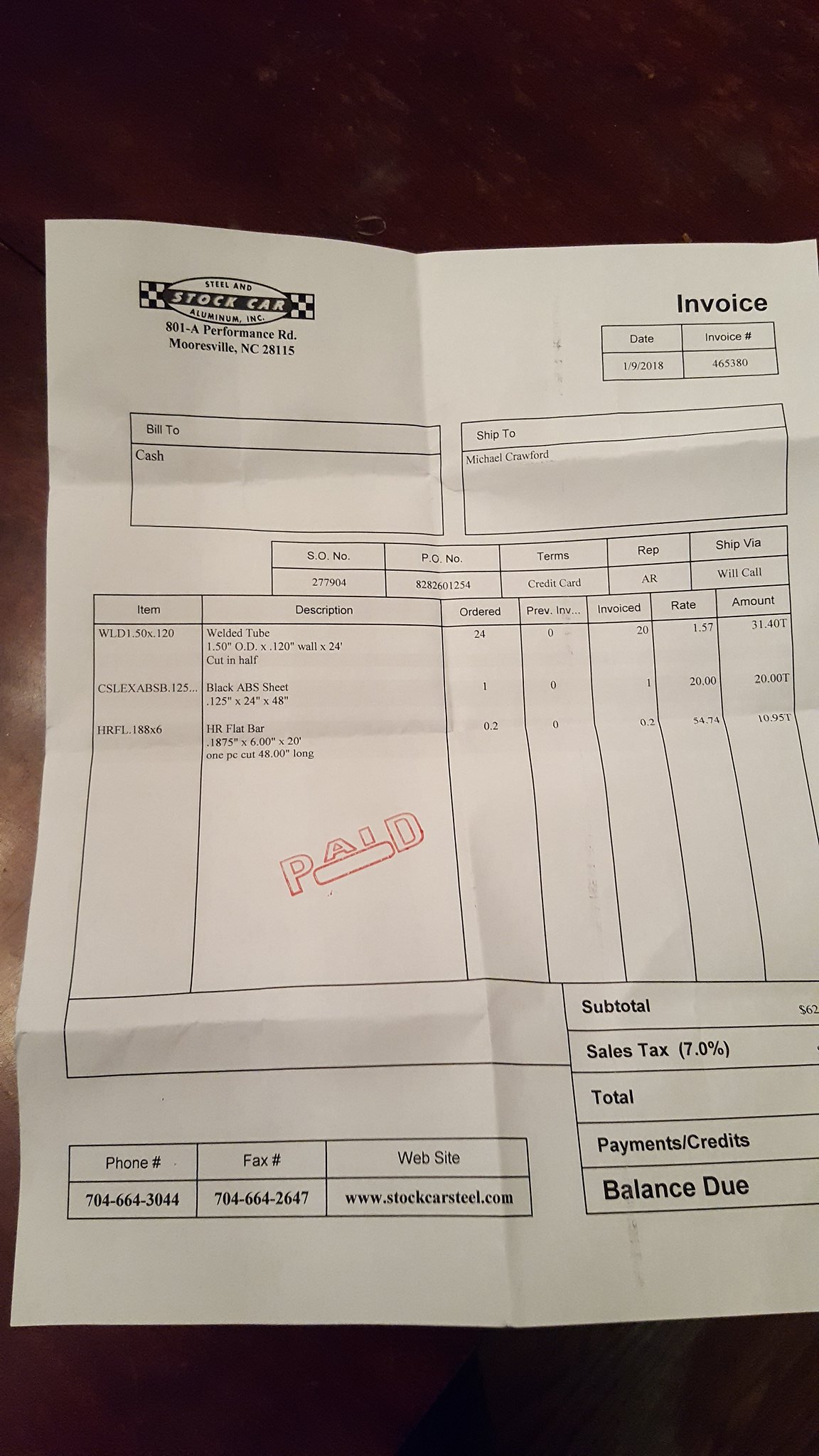

purchased 3/16 plate: 10.95

255lph fuel pump from ebay 13.99

2x2 angle 6 feet 5

new total: 1135.71

recoup: 822

to start with, I figure well talk about parts acquisition.

Was told by the spec miata shop that they were unable to locate the stick of cage tubing that I got with my rollbar. He told me to buy a stick and he would reimburse me, which he did. So I went to stock car steel over in moresville and picked that up, as well as some 3/16 plate, as that is the SCCA requirement for a bolt in roll bar. Also got a sheet of plastic for another project while I was there. No picture, because it looks like a piece of steel plate.

20180109_182527 by Michael Crawford, on Flickr

20180109_182527 by Michael Crawford, on Flickr

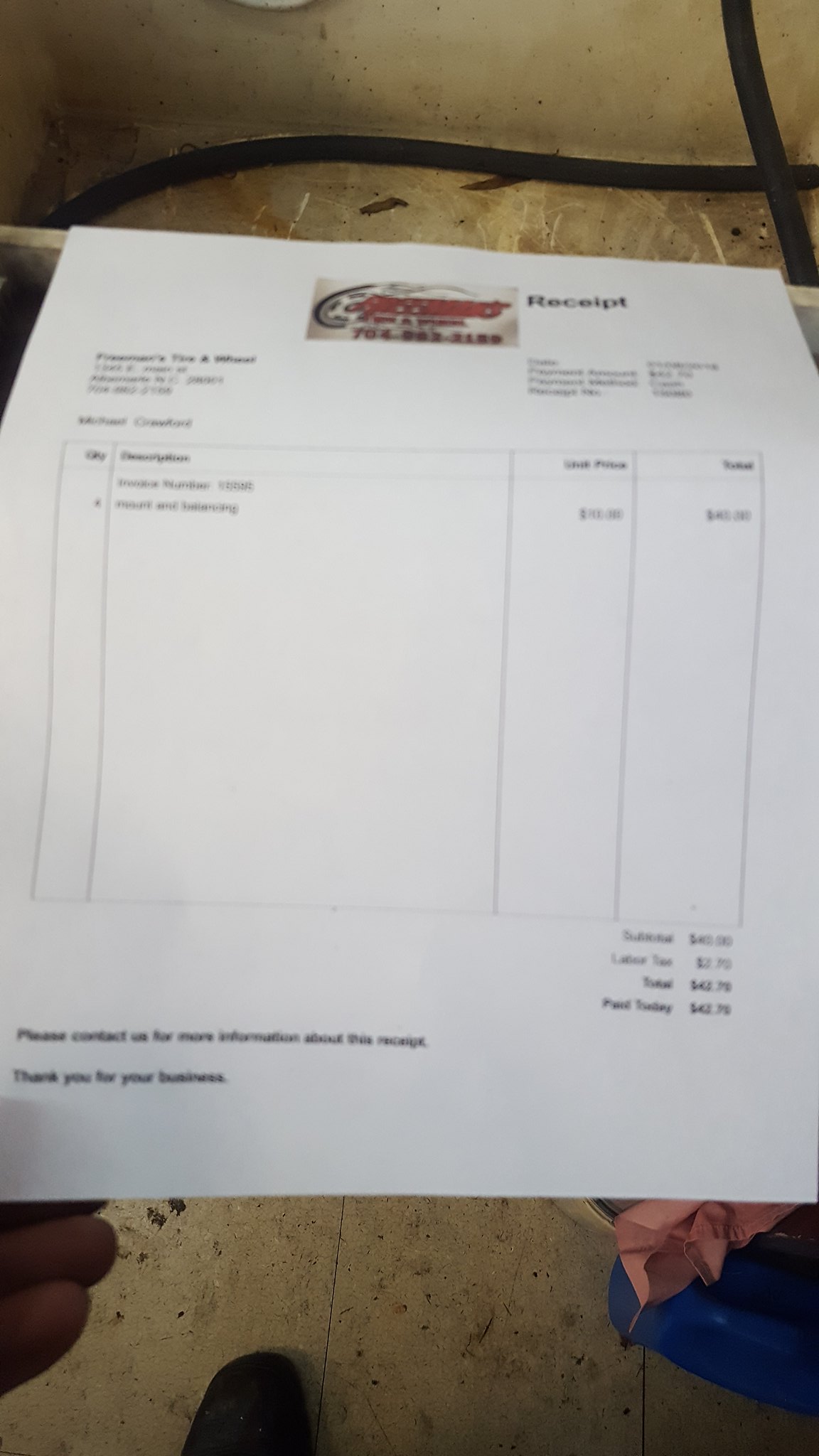

got the spec miata slicks mounted up and balanced on the NB 15s so they'd take up less room. 15X6 wheels, and yes, the slicks are somewhat pinched. Unless someone wants to trade 15x8/9/10 for stock wheels, this will have to do. Toby at freemans tire charged me 40 bucks. 10 bucks each is a pretty good deal.

20180114_114852 by Michael Crawford, on Flickr

20180114_114852 by Michael Crawford, on Flickr

20180109_082520 by Michael Crawford, on Flickr

20180109_082520 by Michael Crawford, on Flickr

20180109_082530 by Michael Crawford, on Flickr

20180109_082530 by Michael Crawford, on Flickr

responded to a facebook marketplace ad for miata parts, asking about struts. I had seen what looked like konis in a picture of the parts stash. After coordinating schedules, dad and I drove to outside of greenville, SC and met a guy named Alex, who parts out miatas for a good portion of his living. Name of the business is SNS Mazda parts. We spent some money.....

20 struts at 10 ea, full drivers side rear suspension to replace our bent stuff, front fender, and inner fenders. Still need to source and NB subframe to replace that bent part. In the struts were a full set of SGX with a spare front and rear, 2 full sets of tokiko Hps, b&g lowering springs for an NA, a full set of speck miata bilstiens, and a bunch of NA tophats. Need to go through them all, then ill start selling off spare crap. A set of the tokikos and stock NA springs may go on my daily NB with NB tophats, as that should lower it 1.5 all the way around.

20180113_101439 by Michael Crawford, on Flickr

20180113_101439 by Michael Crawford, on Flickr

20180113_123917 by Michael Crawford, on Flickr

20180113_123917 by Michael Crawford, on Flickr

20180113_154457 by Michael Crawford, on Flickr

20180113_154457 by Michael Crawford, on Flickr

no pictures of coilover stuff or fuel pump as its still in shipping. Next time...

lastly, an example of how the challenge makes a man resourceful. Were always looking for materials and supplies. I went to an early dinner with brother Dustin and Dallas last night. On the way to dinner, we had to drop off a redbox movie at Walgreen. Coming through their parking lot, we noticed an overflowing dumpster out back where the store is being renovated. A quick peak inside resulted in a “hold my beer and watch this!” moment.

Walgreens dumpster by Michael Crawford, on Flickr

Walgreens dumpster by Michael Crawford, on Flickr

I dug out some quite heavy gauge blue tube and flat stock, 3 seriously heavy duty rolling platforms, and some store fixtures with 1/8 wall 1x1 tubing on ¼ plate bases. All most of the way to the bottom of the dumpster. The manager was cool with it, and we did ask. I ain't going back to jail for free steel.

20180113_182313 by Michael Crawford, on Flickr

20180113_182313 by Michael Crawford, on Flickr

anyway, on to the car.

Dad worked on getting the 2x2 subframe connectors welded in, and then ground down in preparation of mounting the butterfly brace.

20180113_161248 by Michael Crawford, on Flickr

20180113_161248 by Michael Crawford, on Flickr

20180113_161109 by Michael Crawford, on Flickr

20180113_161109 by Michael Crawford, on Flickr

20180103_183357 by Michael Crawford, on Flickr

20180103_183357 by Michael Crawford, on Flickr

20180113_161244 by Michael Crawford, on Flickr

20180113_161244 by Michael Crawford, on Flickr

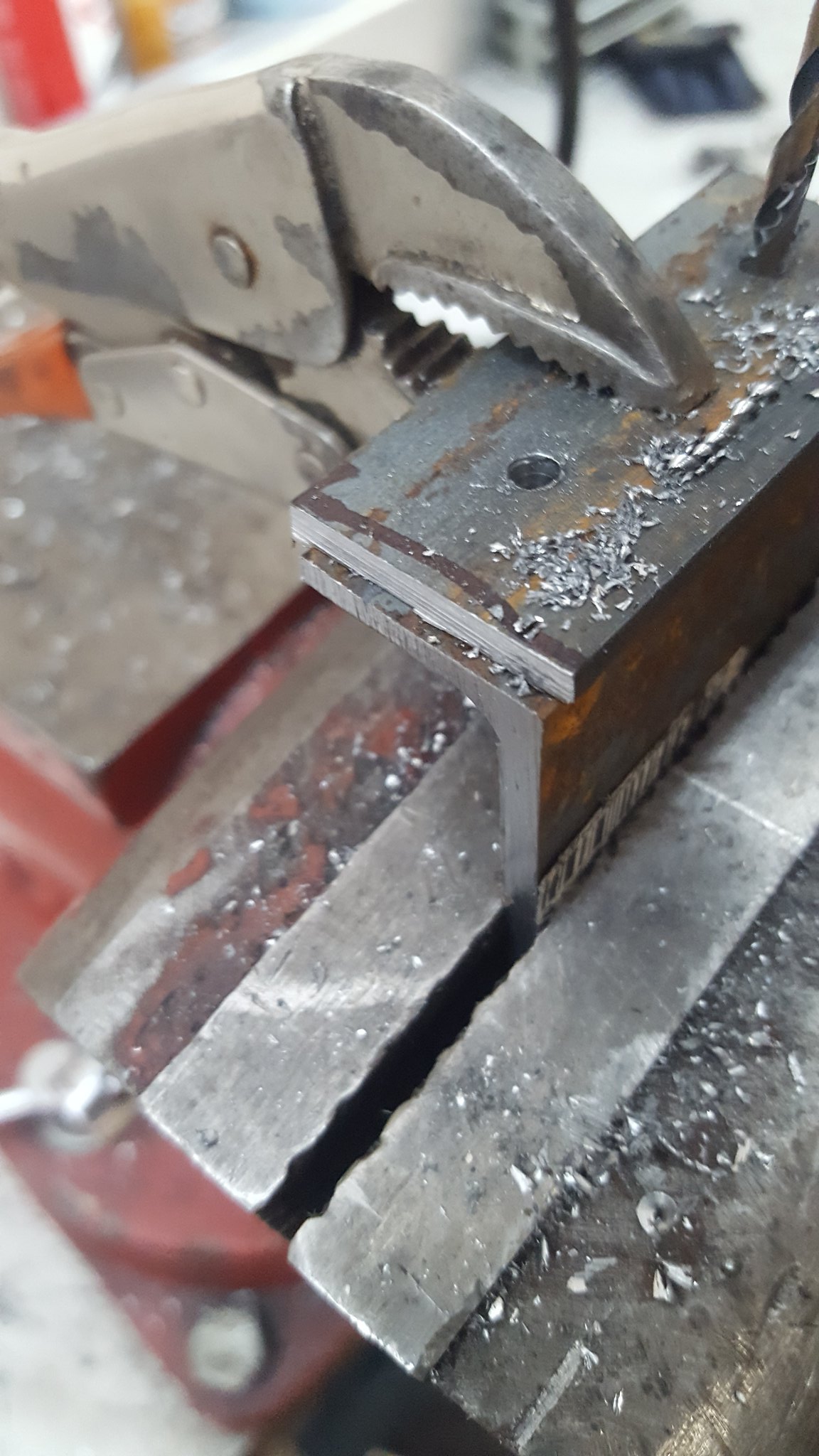

something I did NOT anticipate was the fact that 2x2 is actually narrower than what mazda used, as mazdas rails were not actually square. Which meant that my butterfly brace no longer fit. By about an inch. And not enough room on the 1x1 angle to re-drill the holes. Instead of scrapping the whole thing and starting over, I picked up some 2x2 x3/16 angle, lopped an inch off the vertical side and cut it to length. I still need to get them fitted, drilled, and studded, but were close. With plenty pf extra meat left over.

I also used some of the 1x1 tube and leftover angle to make frog arms. These are ugly in pictures and person, but thankfully will be hidden by fenders. Strong though, and I feel a benefit in addition to the seam welding and subframe connectors. Ive never had a car that I felt was too stiff, and the AMC is my benchmark for stiff enough.

20180106_121253 by Michael Crawford, on Flickr

20180106_121253 by Michael Crawford, on Flickr

20180107_163942 by Michael Crawford, on Flickr

20180107_163942 by Michael Crawford, on Flickr

made an extra pair for the daily while I was at it

20180106_181351 by Michael Crawford, on Flickr

20180106_181351 by Michael Crawford, on Flickr

I then moved on to fitting the roll bar and making the rest of it. Because, really, its cool. It doesn't get us any closer to a running, testable car, but it makes me feel good. So ive got that going for me.

First up was making the bar fit exactly where I wanted it. That required some surgery to the drivers side seatbelt tower. The cutting is done, and ill re-weld it shortly, and then box in the rest to strengthen it back up, but the bar is now perfectly situated. I then obsessed mightily over how to do feet and make it a bolt in. the thing I don't like about my hard dog is how you need 2 people and 7 hands to get the reinforcing plates, nuts, bolts, and bar all assembled. Its a pain in the ass. So my idea is to weld nuts to the backer plates, and pop rivet the plates to the floor pans for location purposes. Genius!

Still have to make the plates and feet though. So I went to google, where every idea someone has ever had has a picture taken of it. I found my inspiration in an article of a blackbird fabworx gt3 install. Pretty much did what I thought I wanted to do, but it was good to see confirmation that I was on the right path.

20180113_161114 by Michael Crawford, on Flickr

20180113_161114 by Michael Crawford, on Flickr

20180112_182238 by Michael Crawford, on Flickr

20180112_182238 by Michael Crawford, on Flickr

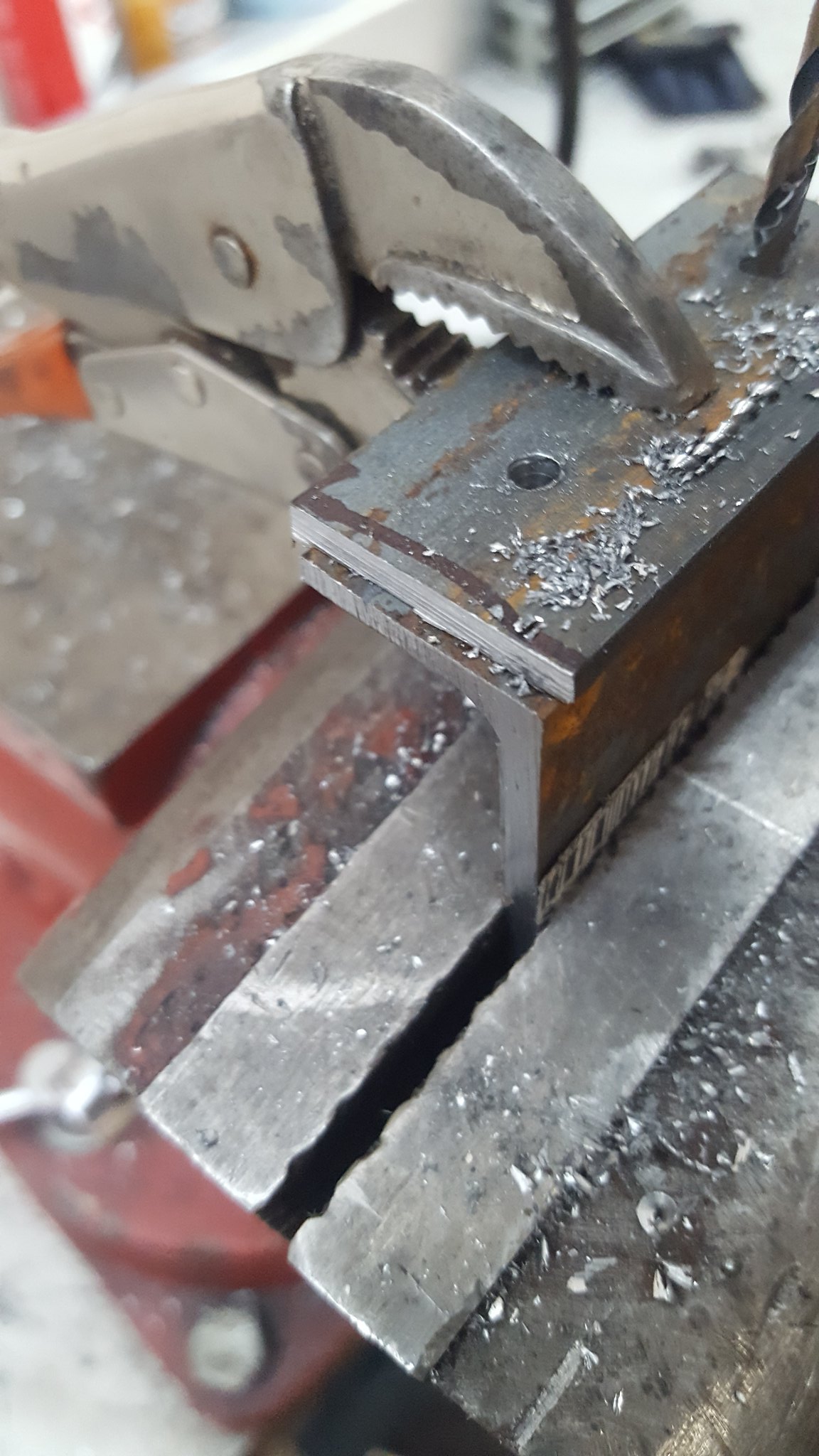

Took my portaband to the 3/16 plate, and after a significant amount of cutting, grinding, and shaping, had the different pieces I wanted. I measured for my holes, and too them home with me for drilling.

20180114_135127 by Michael Crawford, on Flickr

20180114_135127 by Michael Crawford, on Flickr

Pictures of my shop and drilling setup:

20180114_114022 by Michael Crawford, on Flickr

20180114_114022 by Michael Crawford, on Flickr

20180114_114053 by Michael Crawford, on Flickr

20180114_114053 by Michael Crawford, on Flickr

then took it all over to dads this morning and did some welding and final fitting.

20180114_155518 by Michael Crawford, on Flickr

20180114_155518 by Michael Crawford, on Flickr

should tack the hoop to the new plates tomorrow, and finish the backing plates.

While ive been doing that, dads been working on finishing seam welding. We have gone much, much further than flyin miata recommends, and much much further than we planned on. Seam welding is addictive, as I learned on the AMC. Dads learning it on a mazda. Its hard to know when to stop, to be honest.

20180114_162144 by Michael Crawford, on Flickr

20180114_162144 by Michael Crawford, on Flickr

our goal for tomorrow is finish the main hoop feet/attach the hoop to new feet, finish the butterfly brace, make a trans mount, and maybe finish the welding of the 2x2 subframe connectors.

![]()