I will leave this here in the unlikely case that you have not heard of "Project Hugo"

http://www.build-threads.com/build-threads/datsun-240z-projekt-hugo/

The link will lead you to a series of very well made videos about an Epic 240z project.

Pete

I will leave this here in the unlikely case that you have not heard of "Project Hugo"

http://www.build-threads.com/build-threads/datsun-240z-projekt-hugo/

The link will lead you to a series of very well made videos about an Epic 240z project.

Pete

NOHOME said:I will leave this here in the unlikely case that you have not heard of "Project Hugo"

http://www.build-threads.com/build-threads/datsun-240z-projekt-hugo/

The link will lead you to a series of very well made videos about an Epic 240z project.

Pete

Wow, that is an amazing amount of work.

It seems from the 242 page thread on the Swedish forum that it is very very far from completion (last photo I saw the car was still bare and camber plates were being welded to the front towers) and was sold off to someone else?

Not sure if this a friendly hint to maybe rethink my project? ![]()

damen

You guys are right in my back yard. I was just in Spring helping someone move a car yesterday.

I'm sure you have all the hands you need, but if you're looking for a guy to stand around a drink coffee while you do real work, I'm your guy. We can even tell One Lap storied and figure out who we know.

Oh, and beautiful car with a cool story. Nice.

In reply to mazdeuce - Seth :

Hi Seth-

Yes! We will have you over soon! Thanks for joining in here.

damen

Workday: 3, Days Since Delivery: 22

I'm not sure if keeping track of the days will be motivational, or de-motivational. We'll test it out.

Last workday, we stood around and brainstormed a tentative layout for the Datsun corner of the shop. Toolboxes on the back wall, then working surfaces on the sides. Measurements were taken, and toolboxes were shopped.

We settled on one of Harbor Freight's offerings, the 46" 9-drawer mobile workbench with solid wood top. 4 of those would fit nicely in the space we had available. We called around town and found a store that had 4 in-stock.

Unfortunately, the store that had the boxes is like 20 miles away from Nik's. So I drove the 1 hour after work to Nik's, then we hopped in his long-bed F-150 shop truck and set off across town in rush hour to get the toolboxes. Ideally, you would make this journey at some other time of day and day of the week, but between our two busy lives, we don't have the luxury of flexibility.

Then we missed a crucial exit that added another half-hour to the trip.

Eventually we made it to Harbor Freight, picked up the toolboxes, and made our way back, stopping at Rudy's BBQ for some dinner. It was decently late by the time we made it back.

We only had time to unload the boxes, move them into the shop, and do some organizing in one corner.

Perhaps not as much accomplished as we imagined at the start, but it will be pretty sweet to have all those toolboxes/workbenches side-by-side along the back.

And a meal at Rudy's always makes me happy.

damen

Did HF say anything about that particular box being discontinued?

I was looking at it as a possible cabinet for my trailer, but it seems to have disappeared from their website, and my local store doesn't know from nothin'...

In reply to badwaytolive :

Not sure if this a friendly hint to maybe rethink my project?

Not deliberate, but subconscious? Could be.

The Videos on YouTube are amazing and done before YouTube was even a thing, making it even more of an epic thing.

I still troll the net every so often in hopes of finding this one back on the front burner.

As to preaching to others about cutting up classics, I have no defense. My project has sacrificed two out a total build of 8000 P1800ES to make a personal chimeric folly.

In reply to Rodan :

It looks like you're right- that particular box was discontinued at the end of 2017.

On the other hand, I've seen this toolbox in Home Depot and I believe it is the exact same box, just "Husky" instead of "Yukon"

damen

In reply to NOHOME :

I watched the youtube videos; what a huge amount of work to film and edit! Very impressive, as if the resto wasn't enough...

+1 for "chimeric folly"; sounds copyright-worthy!

damen

I like this story and I also like the Datsuns. Some years ago I got to make the tech inspection of a 240Z with a Nissan VQ35DE V6, a really nice car. https://rejsa.nu/forum/viewtopic.php?t=101028

I can also relate to having a family and limited time. When I started the mor serious modifications on my Capri, back in 2005, my daughter was barely 1 years old. We quite quickly found out that the thing that worked in my family was to have that one "given" garage night each week. I had friends who thought it was crazy to make plans like that but it really worked. My wife knew that Monday nights would be set aside for me, she got another night "off" and the rest of the week we cooperated. Of course we re-scheduled sometimes, and whenever suitable I would use more time in the garage.

That also relates to what a friend of mine said when we worked on a book together (he's an established writer, I am a wannabe). He said that the key to being a productive and successful writer is to not wait for inspiration, but rather work with dedication. To some extent I think the same goes for a car project. Sometimes you will have to force yourself to work on the car. It will not always be fun. But I had, and still have, the picture of my target look for the Capri on the note board by my desk:

That was my motivation. When I would sit by the computer doing "nothing", that picture was right there. Telling me to go out and get some work done :-)

You seem to have a great friend with a great workshop! That will be a valuable asset.

With regards to Mull and Project Hugo; here in Sweden it is very quiet about that one. After it was sold, it sort of dropped from the public forum radar. People keep asking about the car every now and then, but who knows?

Gustaf

In reply to therealpinto :

Great link to the 240 build. Thank Google for the language translator, scary how well that works.

In reply to therealpinto :

Hi Gustaf-

Thank you for sharing the excellent advice and 240 thread! I'm glad to hear that the designated shop night is a winning strategy; I hope the structure will keep me on track.

Have you been able to complete your Capri mods?

damen

Great story and project! I have a soft spot for these as well. A very nice looking starting point.

I'd love to have my dad's old 240Z, but it made room for first a '76 280, then an '83 ZX. I did own the ZX for a while, but it is not the same as the earlier models.

Hi everyone-

Not a ton to report from this shop day, but nonetheless a day well spent on organization. The Datsun waits patiently.

Our goal for the evening was to clear off the back wall of the Datsun bay so we can unpack the toolboxes and line 'em up. We made good progress by relocating cabinets during the first work night, but the double-stacked Costco shelves still needed moved.

They'll be going in the spot we cleared out near the roll up door.

We've been doing our best to move items intelligently, trying to put them in a permanent home (which is sometimes in the trash or recycle), rather than just moving piles around in circles. It slows the work rate, but hopefully will reduce the overall work load.

Many steps later, we were able to move the cleared-out shelves into place.

The Datsun is currently sitting in what will be another car work bay. On the other side of the Datsun (and the work bay) is the fabrication area. Nik got some of the big metal Costco shelves to act as a barrier between the two, so we decided now was as good a time as any to start putting those up.

Of course, that meant clearing out a pretty densely-packed area of the shop, then laying down some more vinyl flooring, and then putting up a shelving unit.

Just on the other side of the 818 body panels, we set to work. The progress isn't super obvious at this point (evidenced by Nik's fiancee coming in and asking, "So, what have you guys been doing in here?"), but we'll just keep putting one foot in front of the other until it's done. I'm sure we're not going backwards, so eventually it will be done.

We got the shelf up and loaded some heavy stuff onto it.

Like I said, not a mind-blowing change, but progress anyhow. That was it for the night.

I'm thinking we'll unpack the toolboxes next. That should be pretty sweet.

I promise there will be a car build in here at some point :)

damen

Good luck with that large of a swap!

If you're done by late April, cruise over to Road Atlanta for the Mitty. ![]()

badwaytolive said:In reply to therealpinto :

Have you been able to complete your Capri mods?

damen

Well, complete is a word I don't really know :-) There are some small issues to iron out but I am starting to see the point where it's no longer a project but rather a car you mostly drive. Mostly because I can't wait to start the next project(s)!

But I also need to organise some working space for that. I envy you guys a bit in that you have pretty much space to work with. I'm waiting for an opening to rent some storage, that will release the gordian knot...

I don't know how far you're taking the construction work in your friends place but to me it looks like there's space for a loft in one corner at least. That could give you some great space to store things like body parts and interior when work is being done. That was my biggest challenge when working on the Capri. A car taken apart needs the space of like three cars!

Gustaf

In reply to crankwalk :

Thanks!

Sorry, you didn't specify the year on the "late April", so I'm not sure if I'll be done. If you meant 2021, there's definitely a chance!

In reply to therealpinto :

I agree about the luck of having such a great space to work! It's going to be extra enviable when we're done with the organization and build-out I reckon.

Good thoughts about storage space for disassembled cars, thanks for that. I don't think I will be putting too many original parts back in the car, so I'm afraid I will be selling, recycling, or scrapping many parts. I will certainly let the community here know what I no longer have use for; there seems to be a great number of folks with S30's. Hopefully I can be diligent about moving that stuff out, which would greatly decrease the storage requirements.

damen

Workday: 5, Days Since Delivery: 42

There was a bit more cleaning to do before the toolboxes could be unpacked and placed.

So we finished cleanup on that side. I think we did a pretty decent job finding permanent homes for some large percentage of this stuff.

Clean space is so nice. I'm sure I'll be back to look at this picture and enjoy the serenity.

And it's ready for toolboxes!

After a break for some food, we unpacked the boxes one by one and placed them in their final spots. We had to hammer a lip at the bottom of each of the boxes that kept them from snugging up side by side nice and tightly. We also didn't put the handles on, for obvious reasons.

I'm happy, and Nik's super happy with our progress- this is going to be so nice to work in. Dreams really do come true.

With a little extra time left before I had to head home, we unpacked and assembled 1 of 4 Gladiator cabinets Nik found on special. They were a "damaged packaging" deal which meant we had to do a bit of massaging on the 99 gauge sheet metal as well as track down some hardware of our own. In the end, it came out looking good, so 4 of them will be excellent storage.

That was all we had time for. Not much Datsun content, but the start is getting closer; I can feel it!

damen

Workday: 6, Days Since Delivery: 56

Not much to report from this workday. We spent most of the time assembling the remaining 3 cabinets and moving things around.

Closer, for sure, but not ready for showtime yet. We're pretty optimistic that the patience will pay off. It's really looking good.

damen

if you are bringing your own tools into the shop a suggestion.

My dad, grandfather, and uncle all worked in the same garage repairing cars for some years.

The way they tracked who's tool was whose was fairly simple. They each had a stamp.

Grandpa's was a southern cross stamped into the tool with a punch.

Uncles was the same cross with two dots added to differentiate it.

Dad's was the same cross with different set of two dots added.

a pita to start, but not to maintain.

On jobsites, i spray painted my hand tools pink. Power tools had pink stripes. Nobody wants to borrow pink tools, let alone claim that they are theirs.

In reply to Mad_Ratel :

Good suggestion- thanks for that.

I probably shouldn't say it out loud here, but I try to maintain a "focused minimalist" tool collection. For example, I found myself always reaching for the same screwdriver, even though I had 10 different ones in the drawer, so I got rid of the other 9 and bought a second copy of the one I really like (I'm not quite focused enough to roll with 1 screwdriver). Then I end up with a big box of decent used tools that I give to my friends and co-workers, most of whom repurpose them into starter toolsets for their kids. What's better than that?

As a result of all this, I have a (comparatively) small, distinct tool set. Which is as good as labeling, I hypothesize.

We'll find out!

damen

Workday: 6, Days Since Delivery: 63

Big step accomplished today: the Datsun is in its position for the build!

We didn't really expect to get this far today, but it made sense to move the car for the progression of the shop organization.

Here's where we started the day:

We wanted to get the second big shelf built. It is part of the divider between the car work area and the fabrication area. First we cleared the area for the shelf next to the existing one.

We rolled out another slice of flooring, then hammered the shelf together.

These are my favorite shelves we've used. They look great. Having two up allowed us to get the 818 bodywork really out of the way, which cleared up a lot of space.

At this point, we had built almost all the storage items that Nik had, so it was time to go through and organize all the items on the ground. It's not my shop, and not my stuff, so I wasn't going to be at all helpful with this task. Given that and the fact that the Datsun was in the way of the next organization step, we decided to move it into place.

I could get started!

We rolled the Saab straight backwards out the roll-up door to make room for the Datsun to be pushed back and forward into its spot.

The Saab then moved right behind. Nik speculates that he will work on the Saab once the organization is done. He has a sweet pile of parts waiting to be installed.

With that, Nik started going through his stuff, and I set about taking "before" pictures. I love photos, so I don't waste any opportunity.

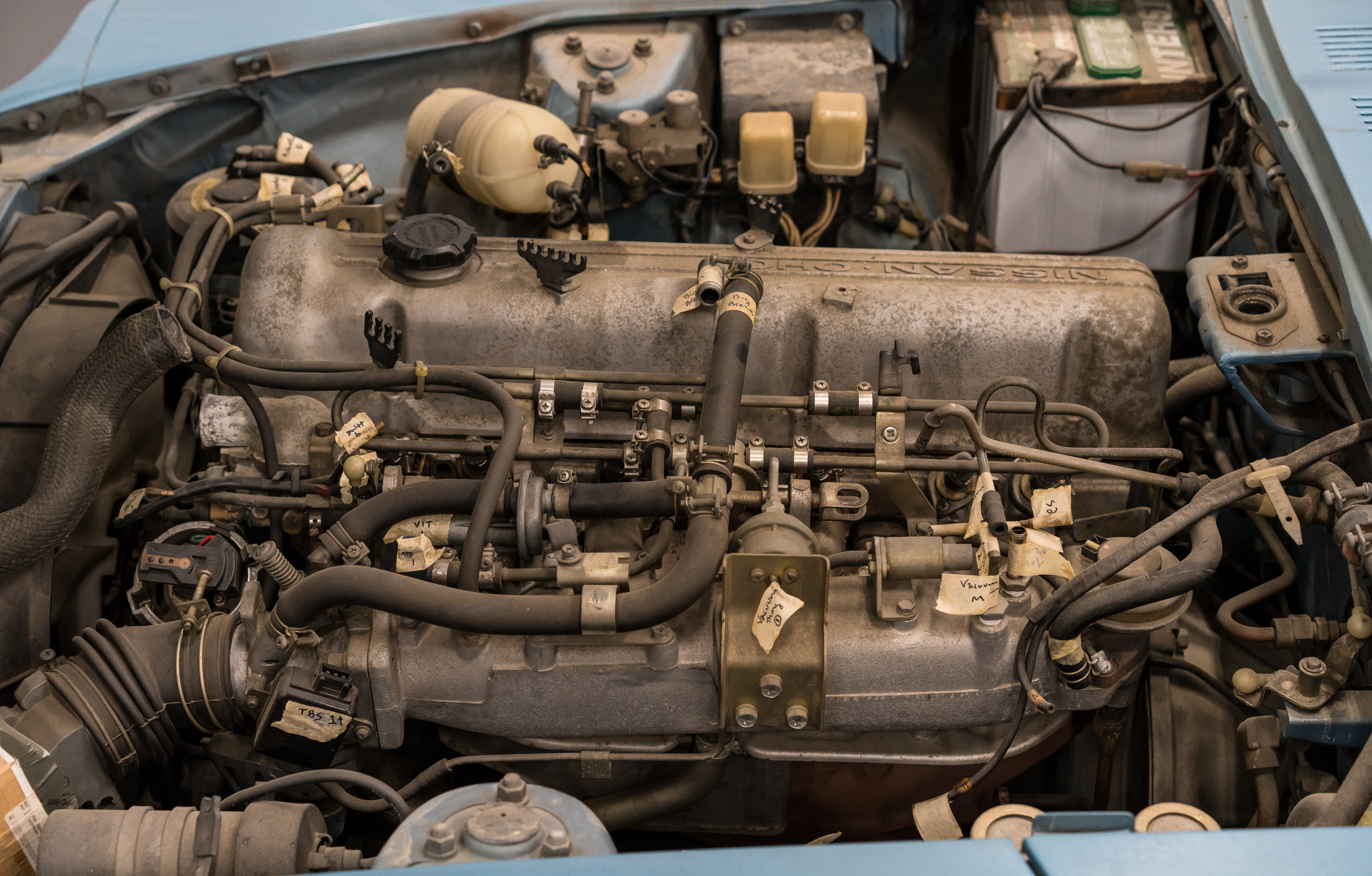

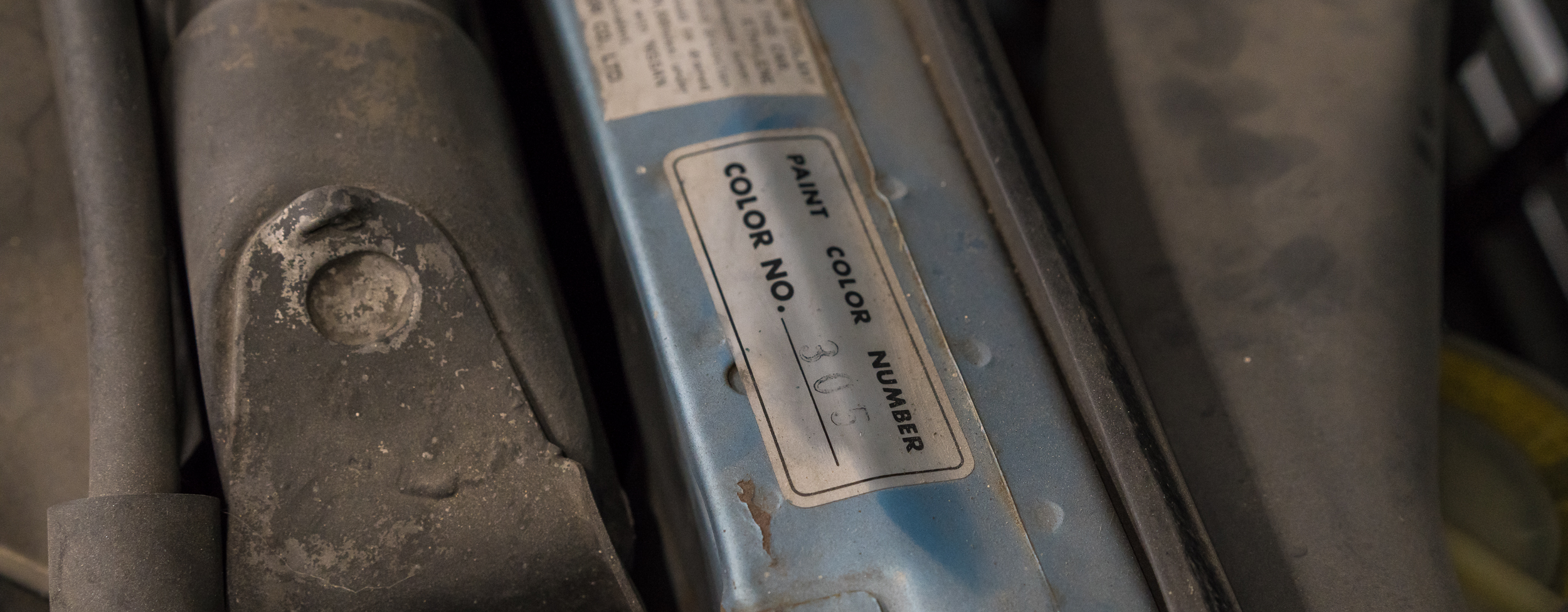

So without further ado, here are the (many) before pictures, officially starting the build!

With a little bit of time left, we decided to get out Nik's wireless car scales and get a before weight.

Unfortunately, one of the scales was not cooperating, so we couldn't get all four connected and running at the same time to get a weight.

We did some light troubleshooting, but with the time up for the night, we determined that we would start with troubleshooting next time. The other 3 are working fine, so if we can't get it figured out, we'll just jack the car up and down and move scales around to get all four corners.

The front row of toolboxes has already proved to be super handy. So much flat surface area! It will take a mighty effort to keep it that way during the project.

I guess next time I'll actually bust out some tools and get to work!

damen

You'll need to log in to post.