tuna55

SuperDork

6/5/11 12:03 p.m.

Before you go through a lot of trouble to swap motors again, do yourself a favor and bring it to a chassis dyno and bring friends. Make sure it's as off as you say it is, and you can easily diagnose why on the rollers. It isn't even close to the price for another engine. Then you can work on overheating.

I can't begin to diagnose overheating from here, but let's say your timing got messed up somehow, there's your power and your overheating. With enough eyes on it on the rollers you ought to be able to diagnose both and leave all of that cool engineering in place.

Starting points for cooling system:

Make sure radiator suction hose isn't collapsing

Make sure thermostat is not too restrictive

Timing

Airflow into and out of the engine compartment (you may want some sort of airflow into a scoop and then some sort of vent out)

Coolant type (didn't read what you were using, but water wetter supposedly does a great job)

Exhaust (You can use header wrap and stuff to keep that heat out of the engine compartment.

220 isn't that hot. If it stops at 220 you're probably fine anyway.

Good luck and keep us posted.

In reply to tuna55:

These are really good suggestions. I already booked dyno time next Wednesday. Between now and then I am going to add some cooling system bleed screws to ensure I don't have an airlock, add ducts between the rad opening and the rad, confirm ignition timing and proper carb operation. I have oxygen sensor bungs on all 4 exhaust pipes so we'll make sure mixtures are good. I may also pressurize the cooling system to make sure I don't have a bad gasket

Update: I did a leakdown test on the engine today and it is 5% on all cylinders on the drivers side (B side) and I ran out of time to do the passenger side. I noticed a mechanical knocking sound that I hadn't heard before and using a stethascope didn't reveal the source. The noise is loudest on the drivers side valve cover and isn't loud on the block or top of the heads so I don't think it's piston/rod related. I think maybe it's something to do with the timing chain so I'm going to pull both heads off this week in order to check the cooling passages, valves, valve springs, cams and timing chain. I will be taking pictures as I go so keep checking this thread. Advice from knowledgable people is welcome.

Please stay with the Jag V12. It makes the car so much more awesome then it would be already.

tuna55

SuperDork

6/6/11 12:33 p.m.

loosecannon wrote:

Update: I did a leakdown test on the engine today and it is 5% on all cylinders on the drivers side (B side) and I ran out of time to do the passenger side. I noticed a mechanical knocking sound that I hadn't heard before and using a stethascope didn't reveal the source. The noise is loudest on the drivers side valve cover and isn't loud on the block or top of the heads so I don't think it's piston/rod related. I think maybe it's something to do with the timing chain so I'm going to pull both heads off this week in order to check the cooling passages, valves, valve springs, cams and timing chain. I will be taking pictures as I go so keep checking this thread. Advice from knowledgable people is welcome.

I wonder if you ruined whatever actuates a valve or two. That could explain the ticking and the low power. Keep us posted.

Since I'm already going to have the cams out, I am going to get them reground to a full race profile-it's suprisingly cheap to do and should really wake up this engine.

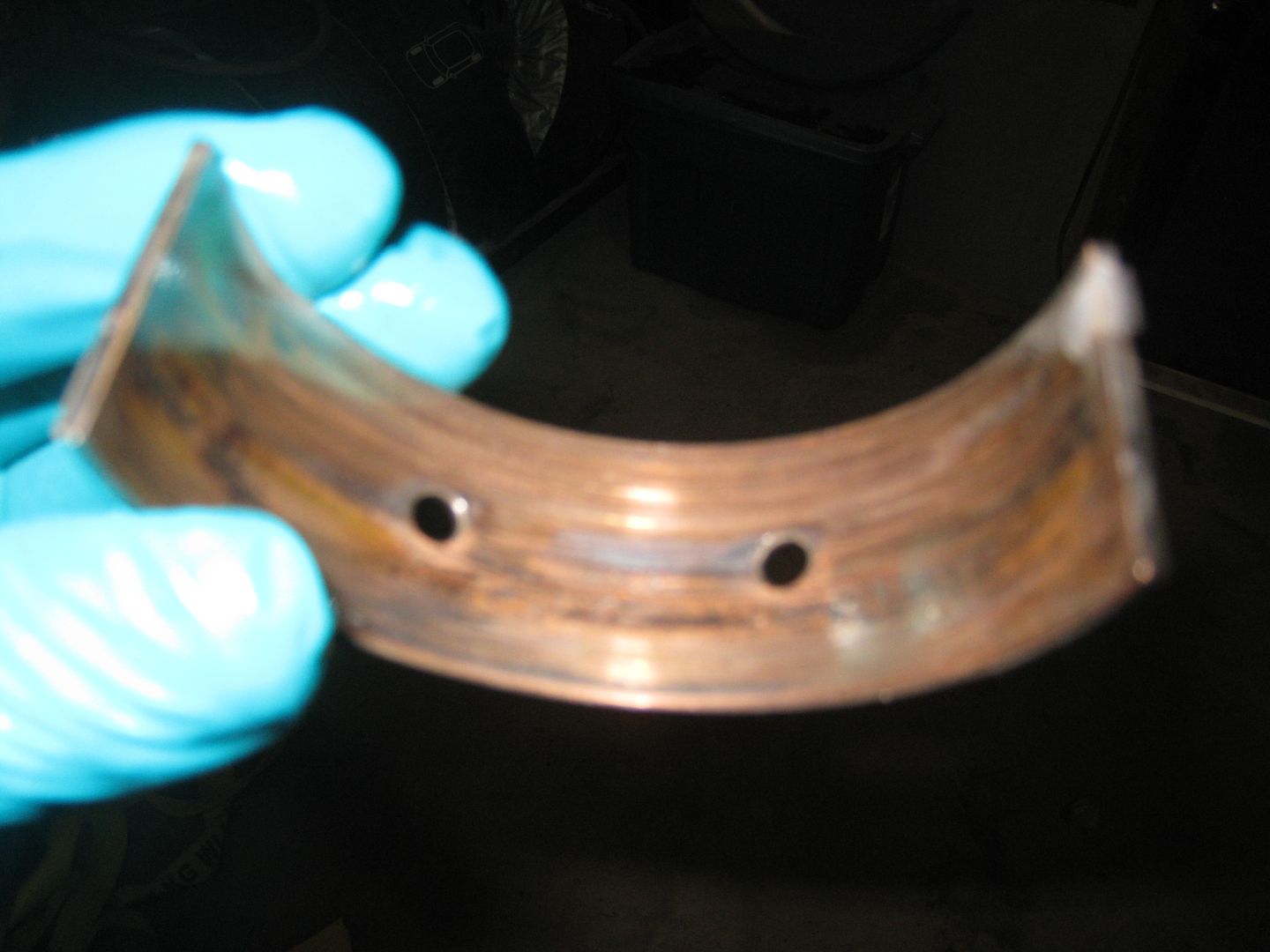

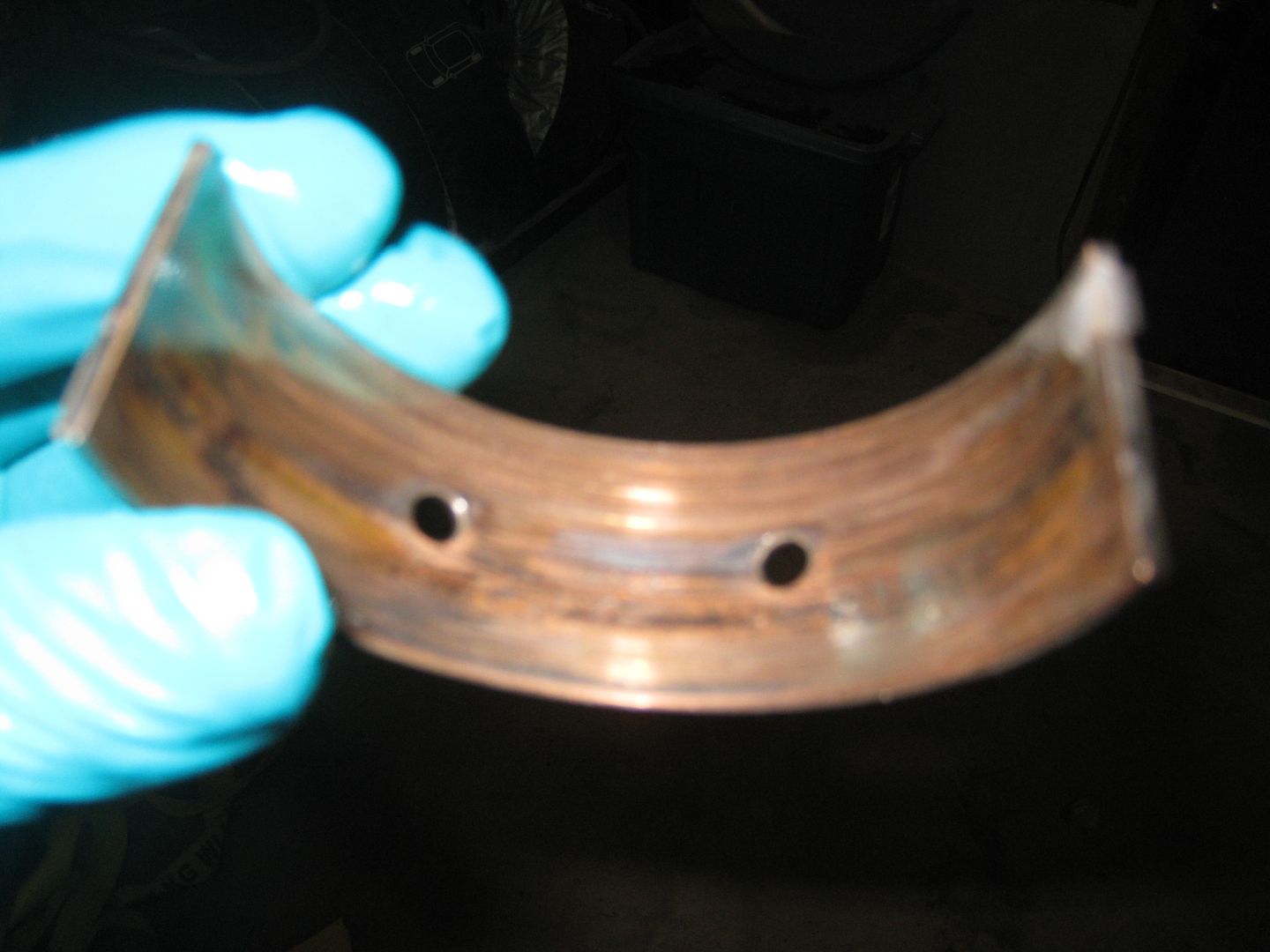

I pulled the oil pan off and found a thrust washer staring up at me from the bottom of the pan.

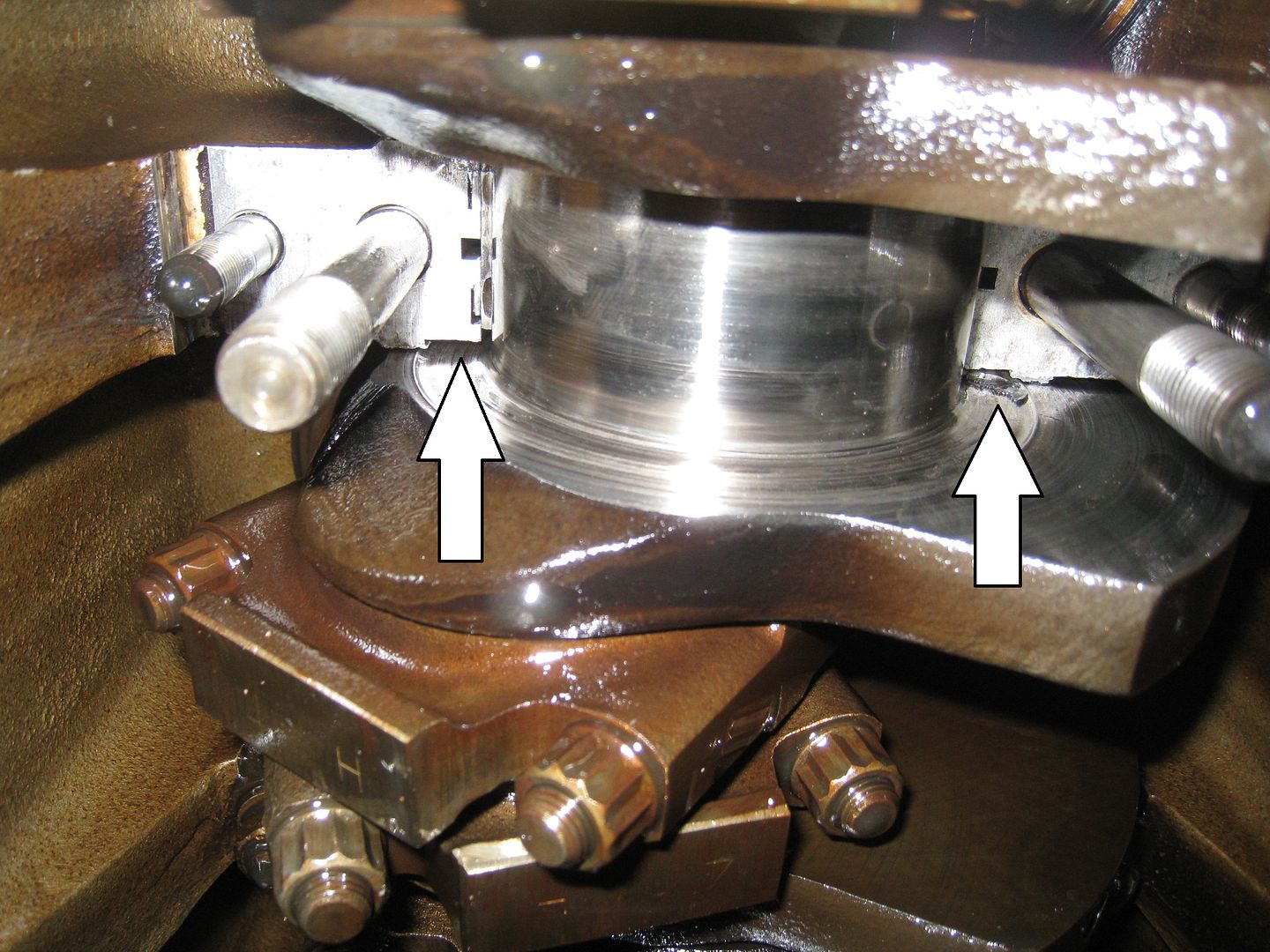

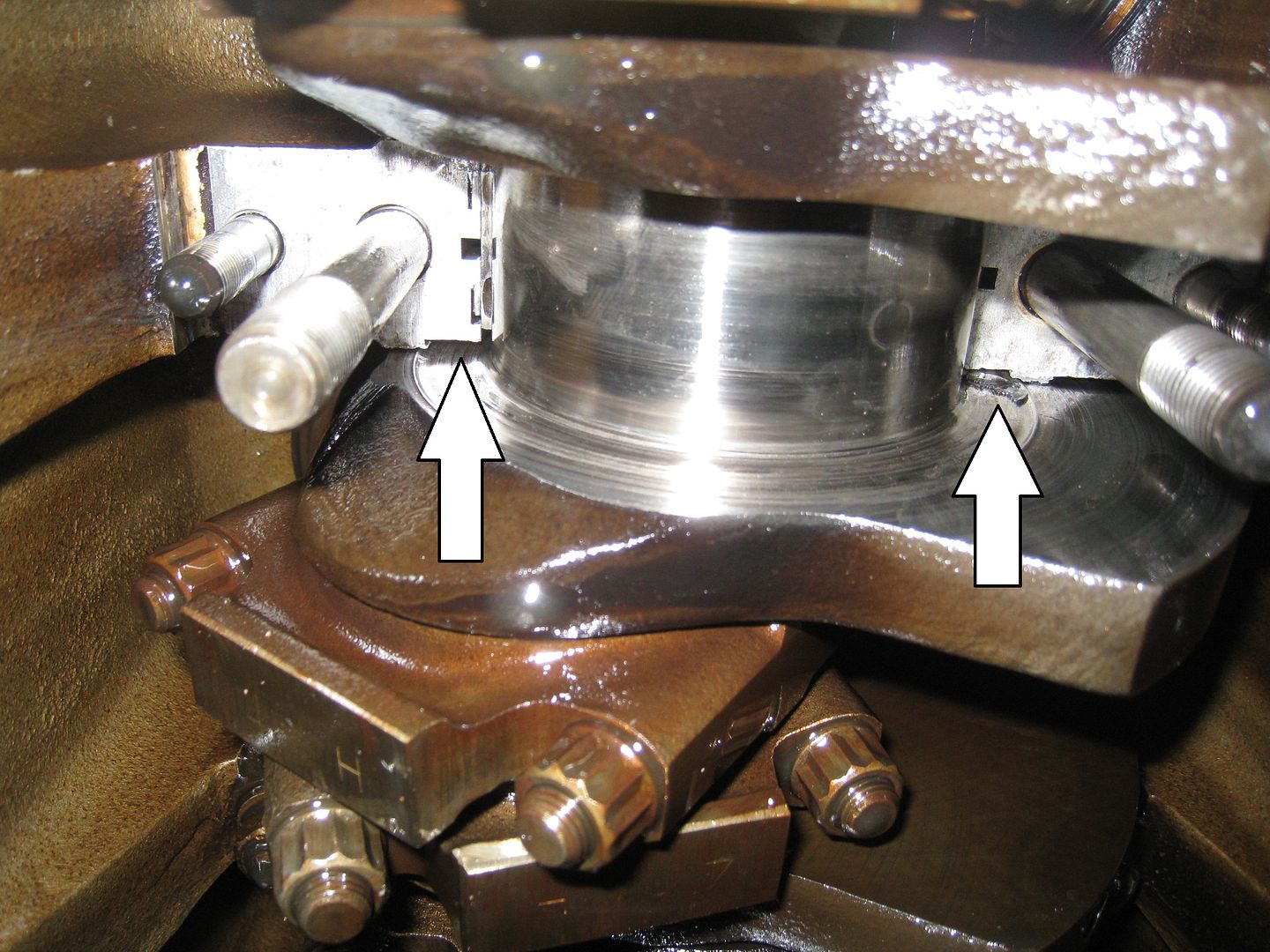

Further investigation revealed the cause. The input shaft on the transmission was pushing the crank forward with enough force that the crankshaft ground itself through one of the thrust washers, allowing the one on the opposite side to fall out. Look carefully at this picture and you can see the groove worn in the crank (left arrow) where a thrust washer used to be, and can just make out what is left of the thrust washer poking out (right arrow).

The crank now has a deep groove where it's not supposed to and all the crank and rod bearings are shot.

The question is: do I buy another engine or replace the crank and bearings on this one? This may or may not have been the cause for overheating and low power but I won't know until it's fixed and there could still be other issues like head gaskets, timing chain, etc. Any other engine I buy may have it's own problems. The cost is about the same for fixing the crank/bearings or buying another engine.

If the cost is the same, i'd fix it, then. That way there isn't any real gamble about what you end up with.

Agreed. Fix the engine you are familiar with.

tuna55

SuperDork

6/7/11 10:14 a.m.

The devil you know... Fix it.

Swapping motors makes sense if you're talking about small displacement really common cheap Japanese motors... and that's about it.

AFAIK by the time you reach that point you have knackered both block and crank? Hope not.

I would think you could find another Jag V12 fairly easy. People tend to scrap them because they are a pain. If you could find one cheap, I would just pull the crank from that one and plus then you have a bunch of extra parts.

93EXCivic wrote:

I would think you could find another Jag V12 fairly easy. People tend to scrap them because they are a pain. If you could find one cheap, I would just pull the crank from that one and plus then you have a bunch of extra parts.

Just like the one he had you mean!

I say re-build it. If you can do that for the same $$'s as buying another it has to be the right decision. That way you'll have a known engine. If your rebuilding it anyway you can probably do a few 'while your in there' things for cheap that should pay off down the line. Deck the head and block for more compression, light P&P onthe head, balance etc. Compare that to another unknown engine that could 30 seconds away from a big bang itself. You have no way of knowing it the used engine has been over reved, overheated, starved of or run low on oil or a multitude of other hidden issues.

I say rebuild it with race cams. Hi rpm V12 wohoo!

The problem with rebuilding it is that even after spending $1000 on a new crank, bearings and gaskets, I could still have an engine wounded by overheating and low oil pressure. The cams and cam bearings may be shot, the valve seats could be ready to fall out, the engine may still overheat and may still be underpowered.

loosecannon wrote:

The problem with rebuilding it is that even after spending $1000 on a new crank, bearings and gaskets, I could still have an engine wounded by overheating and low oil pressure. The cams and cam bearings may be shot, the valve seats could be ready to fall out, the engine may still overheat and may still be underpowered.

Sounds like you're looking for the group's blessing to swap this motor for a different one, but anyone with the design, fabrication, mechanical and organizational skills that are shown off by the Pink Panther needn't ask blessing or permission, so I'm just confused I guess. In any event, I vote pull the valve covers on the motor you have and see what the cams and bearings look like before you spend any more money - if you see obvious damage you have an easy answer.

tuna55

SuperDork

6/7/11 1:10 p.m.

loosecannon wrote:

The problem with rebuilding it is that even after spending $1000 on a new crank, bearings and gaskets, I could still have an engine wounded by overheating and low oil pressure. The cams and cam bearings may be shot, the valve seats could be ready to fall out, the engine may still overheat and may still be underpowered.

Agreed with the last poster, it does seem odd that you're asking for permission.

I don't think 220 is overheated. You can buy a new engine and steal the crank out of it for way cheaper than $1k, but at least inspect the rest of the engine before proceeding. At the rate at which you built this thing you should be able to tear down that engine in about 24 seconds.

I don't know if there's enough thrust bearing cheek left on this crank to regrind. At the very least, you'll need a good donor core. Also, how much pressure plate spring rate are you running and is it too much? If you decide to fix the motor, I'd hate to see it happen again.

tuna55 wrote:

loosecannon wrote:

The problem with rebuilding it is that even after spending $1000 on a new crank, bearings and gaskets, I could still have an engine wounded by overheating and low oil pressure. The cams and cam bearings may be shot, the valve seats could be ready to fall out, the engine may still overheat and may still be underpowered.

Agreed with the last poster, it does seem odd that you're asking for permission.

I don't think 220 is overheated. You can buy a new engine and steal the crank out of it for way cheaper than $1k, but at least inspect the rest of the engine before proceeding. At the rate at which you built this thing you should be able to tear down that engine in about 24 seconds.

I'm not asking permission as much as trying to benefit from the collective wisdom of fellow petrolheads. With this project I have always known what direction I wanted to go in and just headed straight for it, but this has thrown a wrench in the works. I am getting lots of advice on which way I should go so let me break down the different options:

Rebuild this V12-$1000.00-Plus: Nostalgia, cool factor, justifies all the hours spent engineering the car to fit this engine. Minus: After fixing the crank/bearings, the engine could still be damaged from the overheating, may overheat still and could still be underpowered.

Buy another V12-$1500.00-Plus: Cool factor, justifies all the hours spent engineering the car to fit a v12, probably fuel injected and less trouble, probably has no issues. Minus: Will almost certainly be underpowered and is still 250 lbs heavier than a V8, could have it's own set of issues.

LS1-$4000.00-$6000.00 depending on cost of engine-Plus: 250 lbs right off the front of the car, at least another 100 hp, reliable, easy to tune, easy to get more power, could make the car a championship contender, it fits the space left by the V12. Minus: So much money! Boring (as an engine swap, not to drive), making the swap would take a while.

Ford 5.0-$1000.00-Plus: Inexpensive, 250 lbs off the front of the car, easy to tune, cheap to repair, cheap to modify, would bolt right to current tranny. Minus:Not very cool, not very interesting, underpowered

The V12 is way way cool and all - but it's a tool for nationals. Use the best tool available for the resources you have at hand. When you had a v12 sitting around - that was the tool for the job - now that it has some issues the question is more like can you reproduce 300hp/300 ft/lbs for less than fixing the 12? I think you're suspecting or at least fearing more than the crank/bearing issue as a fix. Yank the 12, drop in a sbc/sbf and have at it. Keep the 12 in the corner and when resources/interest are there see about fixing/replacing. My point is don't get sentimental on the drivetrain if it prevents you from doing what you need to do. - edit - I think you can hit the power numbers for a $1,000 (coming from a guy with a junkyard 5.0 mgb/gt with 275hp/300 built for well under $500).

tuna55

SuperDork

6/7/11 1:55 p.m.

Think of it like this. You're 80 and talking to your grandkid about cars, and he would love to enter the 205X Challenge. You tell him one of two stories:

A) So I once put a Jag V12 in an MGB GT and raced it. Yeah, it overheated at first and it spun a few bearings, so I rebuilt it and then it made 100 hp more than stock and kicked ass. I may not have won any championships, but the build process was amazing and I actually still have it...

B) So I once put a Jag V12 in an MGB GT and raced it. Yeah, it overheated at first and it spun a few bearings, so I dropped in a 302 instead. I got bored a few months later and bought a beige Camry. Still have that Camry, want to see?

bluej

Dork

6/7/11 2:49 p.m.

You want the V12, otherwise you wouldn't be hemming and hawing over it now. Maybe you need to step back for a day and reconsider long/short term goals. You've built an awesome chassis and it sounds like your ultimate goal was a very unique car for nationals. Maybe the answer is to swap in that ford mill to run with this year, then take the time to build a known strong v12 for next year.

oldtin wrote:

The V12 is way way cool and all - but it's a tool for nationals. Use the best tool available for the resources you have at hand. When you had a v12 sitting around - that was the tool for the job - now that it has some issues the question is more like can you reproduce 300hp/300 ft/lbs for less than fixing the 12? I think you're suspecting or at least fearing more than the crank/bearing issue as a fix. Yank the 12, drop in a sbc/sbf and have at it. Keep the 12 in the corner and when resources/interest are there see about fixing/replacing. My point is don't get sentimental on the drivetrain if it prevents you from doing what you need to do. - edit - I think you can hit the power numbers for a $1,000 (coming from a guy with a junkyard 5.0 mgb/gt with 275hp/300 built for well under $500).

I like the way you think. A friend is giving me a 5.0 that has a few go fast items on it and it would bolt directly to my T5-it's hard to argue with free.