I punched all the numbers into my suspension calculator and it told me that I can remove both sway bars, soften the rear suspension (actually told me what motion ratio to use on the rocker arms) and set my rear roll center to 5 inches. This is all good until I went to bolt the rear wheels on and found that the passenger wheel interferes with my Woblink mount. Putting extra wheel spacers on changed my track width which required setting the roll center height to 6", which also turned out to be a problem. Above 5 inches, the top of the Woblink gets too close to the crossmember. So, I sorted out how to get the bracket to clear the wheel but I still want to have the ability to raise the roll center above 5 inches so I am going to put an arc in the crossmember. I'll have to reinforce it to maintain some stiffness but I don't see any problems with this.

Interesting you are getting rid of the swaybars. You should read Steve Hoelscher's no bars setup stuff. I'm using it on my Daewoo and really like the results so far.

I keep meaning to check out Hoeschler's stuff. Sounds interesting. loosecannon, the Woblink fab work etc is great! My main concern (and I am sure you thought of this already): is the mount going to hit the ground at full suspension compression?

Curmudgeon wrote:

I keep meaning to check out Hoeschler's stuff. Sounds interesting. loosecannon, the Woblink fab work etc is great! My main concern (and I am sure you thought of this already): is the mount going to hit the ground at full suspension compression?

The mount actually sits above the bellypan, diffuser and floor height so if it hits, there will be a lot of damage to other bits as well.

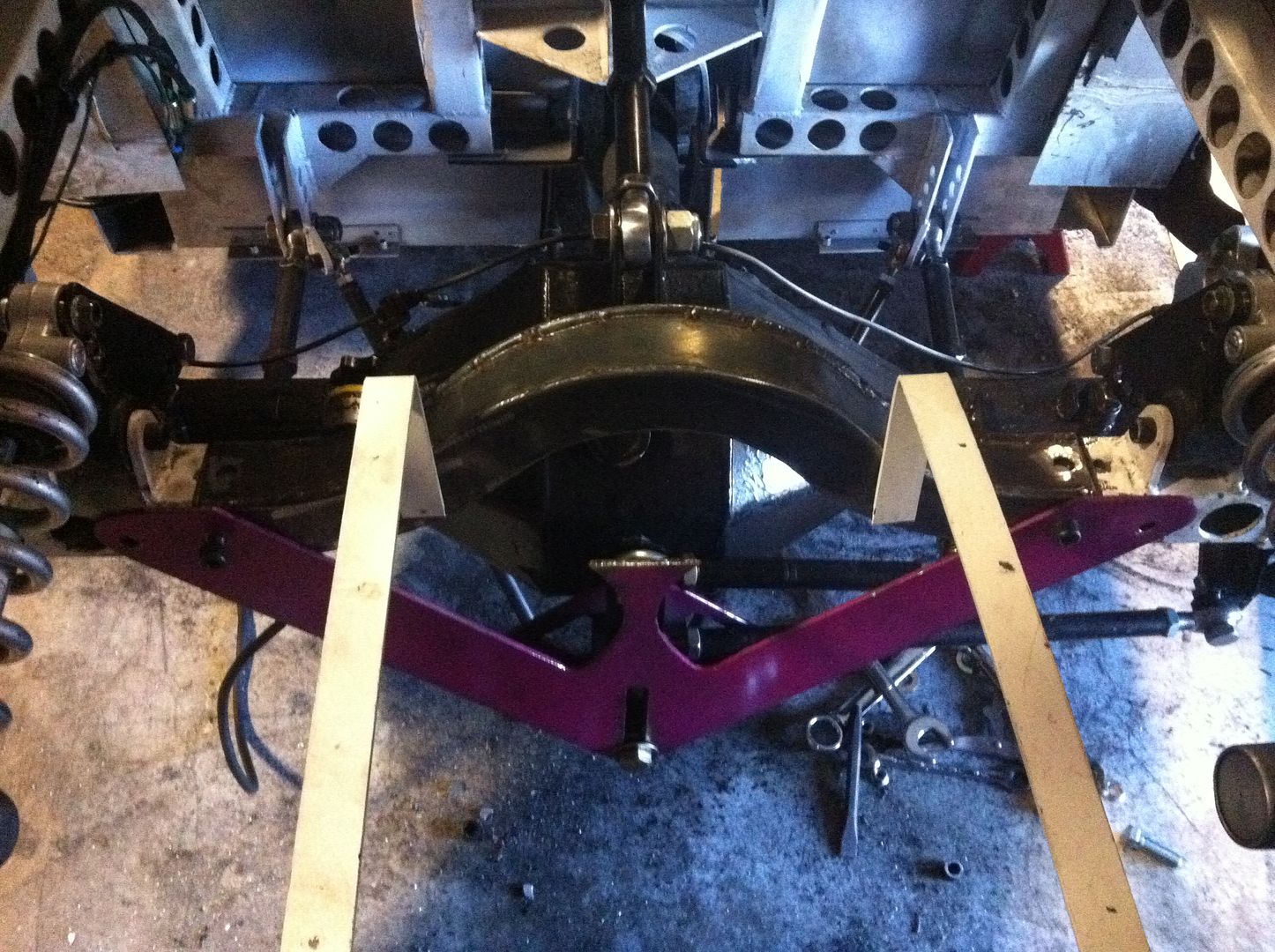

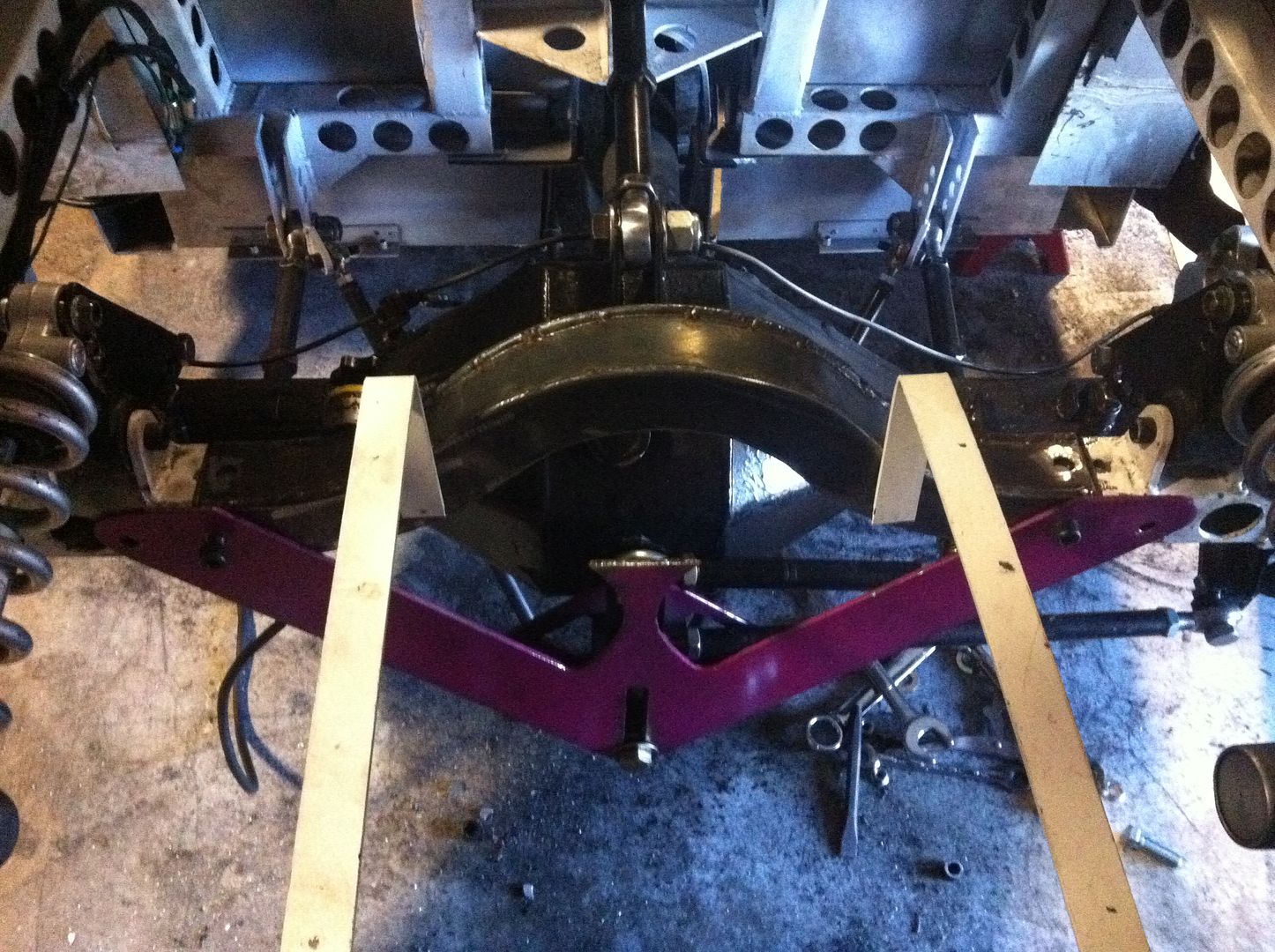

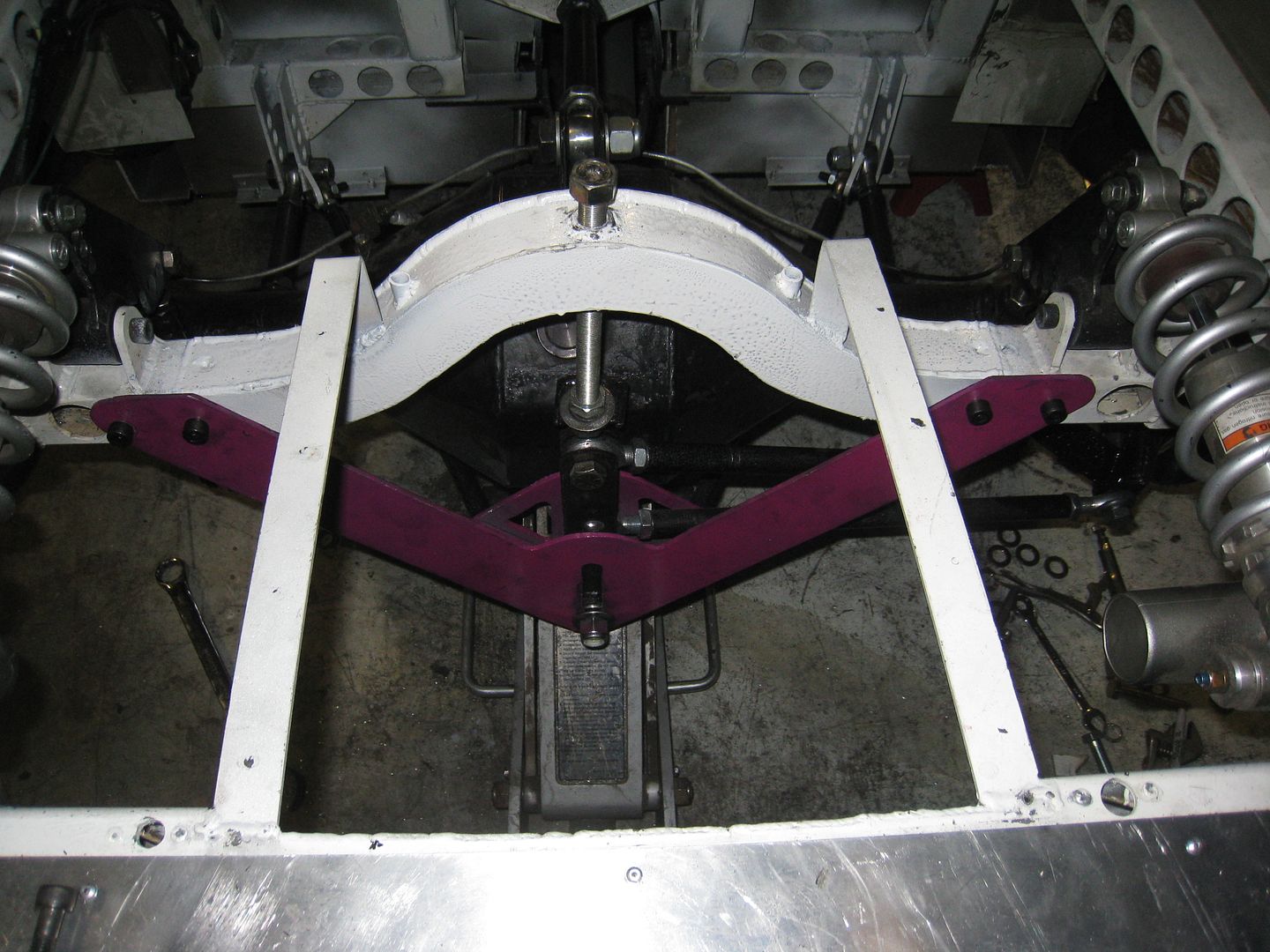

I built a curved crossmember out of 1/8" sheet metal and put a sleeve inside where it attaches to the old crossmember. It's not welded in yet but here's an early look at it.

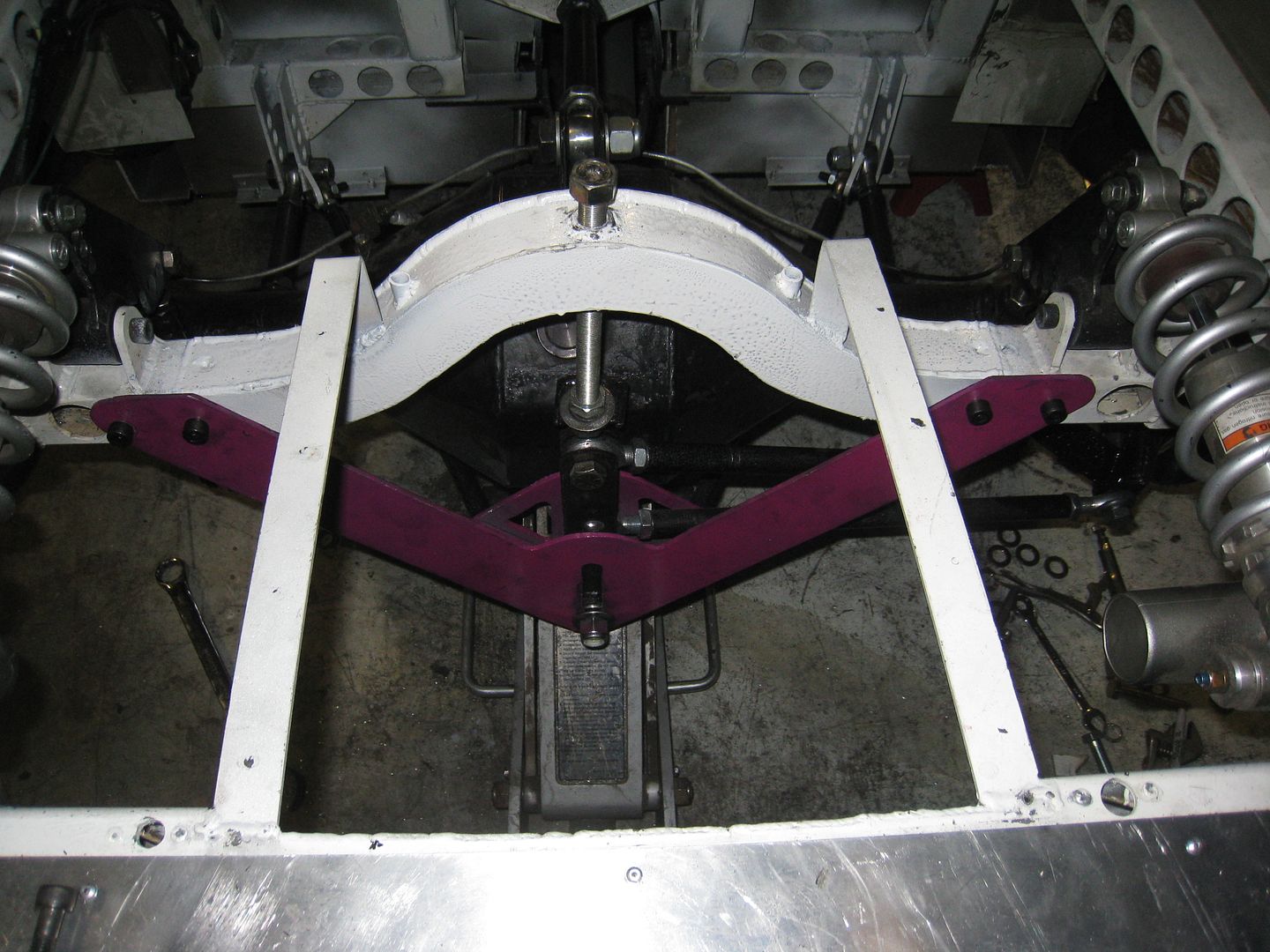

I welded the new crossmember in and decided that adjusting the roll center was going to be too difficult to do between runs once the diffuser and everything was bolted on. I built a screw jack into the crossmember and now I simply have to turn the rod up or down and it moves the roll center. Since I weighed the car last I added a ram air system, a tach, bigger battery, belly pan and the new rear suspension but removed both sway bars-this stuff added 108 lbs, which is disappointing. Still, I think the benefits of all the changes far offset the extra weight.

mguar wrote:

In reply to loosecannon:

Have you considered IRS? It will achieve what I think you're asking for.. If you find a IRS from an XK-E it's a 50 inch track like your MGB.

It will easily handle all the power you can make.. (The 427 Cobra used it) Plus I'm sure you will lose weight..

Incidentally it's real simple to convert a XJ-S or XJ-12 rear end to the 50 inch track.. Chop the lower link. and weld it together You can even make it more narrow to reduce the track width..

The Upper drive links, can be made like shortened drive shafts..

It's possible to get ratios from 4.88 through 2.77

Out of curiosity has any work been done on power curves versus shifting?

I found when I ran autocross with a quick change final drive it was possible to stay in one gear through the whole course.. It turns out I was faster that way than shifting..

No, the guys who win Nationals run live axle so I know that works. My entire rear suspension weighs only 300 lbs including bars, wheels, tires minus the shocks and I doubt IRS would have any benefits. I only calculated the gear ratio I need to go 80 mph at redline in 2nd and that is 3:1, which is what I have.

Haha,yes but you want to BEAT the guys that win nationals right?.

kevlarcorolla wrote:

Haha,yes but you want to BEAT the guys that win nationals right?.

I would get more bang for my buck by going to a fiberglass body kit, aluminum diff and more power.

Looks nice. I like the crossmember. I've heard that type of setup behaves a little different left vs right (just like a PHB) what did you find during your research? It definately has some appeal due to its adjustability.

I would say your doing good if you are 300 lbs including wheels. If you were to go IRS you probably wouldn't lose any weight (my mg wouldn't handle near the power and weighs nearly 250) and as you pointed out a lot of the champions run solid.

That said the JAG rear isn't a great baseline for a performance IRS. It works and handles power but that upper axle link is a pain to design around for a ground up suspension design. If I where re starting I would run a dedeon rear (like JAG had on one of their early racers). You get all the benifits of a solid axle (easy tuning, easier design, good smooth pavement performance) and most of the benifits of IRS (lower unsprung mass, easily adjusted camber/toe). Sure there are compromises (slightly higher weight, not independent) but for the club racer it would be hard to beat. IRS is hard to get right and for most track oriented use can be avoided with favorable results.

Sorry for th hijacked. The project looks great and I am jealous of the speed you work at. Looks like you will be tearing it up in 2012!

Curmudgeon wrote:

I keep meaning to check out Hoeschler's stuff. Sounds interesting. loosecannon, the Woblink fab work etc is great! My main concern (and I am sure you thought of this already): is the mount going to hit the ground at full suspension compression?

If you want it minus all the BS of having to sign up for MR2oc.com, I can pass it along.

I signed up for MR2OC a couple days ago.  But thanks.

But thanks.

On IRS vs. stick axle (from someone who loves IRS adjustability and has built/adapted it to different cars): IRS has no real life average guy performance benefit which makes it worth the extra fabrication etc unless there's bumpy pavement. F1 uses it mainly because it helps keep the overall car shorter and they have millions of $ to pour into R&D.

The Jag setup which uses the axle shaft as the upper control arm is a compromise to save money. It has a funky camber curve and camber was adjustable only by changing shims between the diff and axle. It was mounted in rubber also, if you want a real eye opener jump on the gas in one that has soggy/worn bushings and hang on.  Better'n coffee to wake you up. Sure it's been used under all kinds of different cars but IMHO the Miata's IRS is much better designed.

Better'n coffee to wake you up. Sure it's been used under all kinds of different cars but IMHO the Miata's IRS is much better designed.

Mguar you are correct it was Maseratti that I was thinking of not Jaguar.

mguar, I'm a slow old fart too.  I built the rear suspension in the Abominaton (rotary Spitfire) completely from scratch, using Miata uprights and a 2nd gen RX7 differential. Learned a lot!

I built the rear suspension in the Abominaton (rotary Spitfire) completely from scratch, using Miata uprights and a 2nd gen RX7 differential. Learned a lot!

I adapted a Miata subframe to an Opel GT, now THAT was a a project. It had to be narrowed, then the rear frame rails reconfigured for mounting and clearance...

Then there's an Italian orphan out there which has a lot of Me Otter stuff under it... shhh.

I swapped all the rubber out on the rear suspension of both of my dad's E types.

I needed to build some custom tools to use on the car so today I tackled a couple of tools that will make working on the car a whole lot easier. The first thing I needed was a way to jack up the back end of the car, there was simply no place to put a floor jack. I built a folding steel piece that slides into the rear tow hook holes and has a round plate that fits perfectly onto my floor jack.

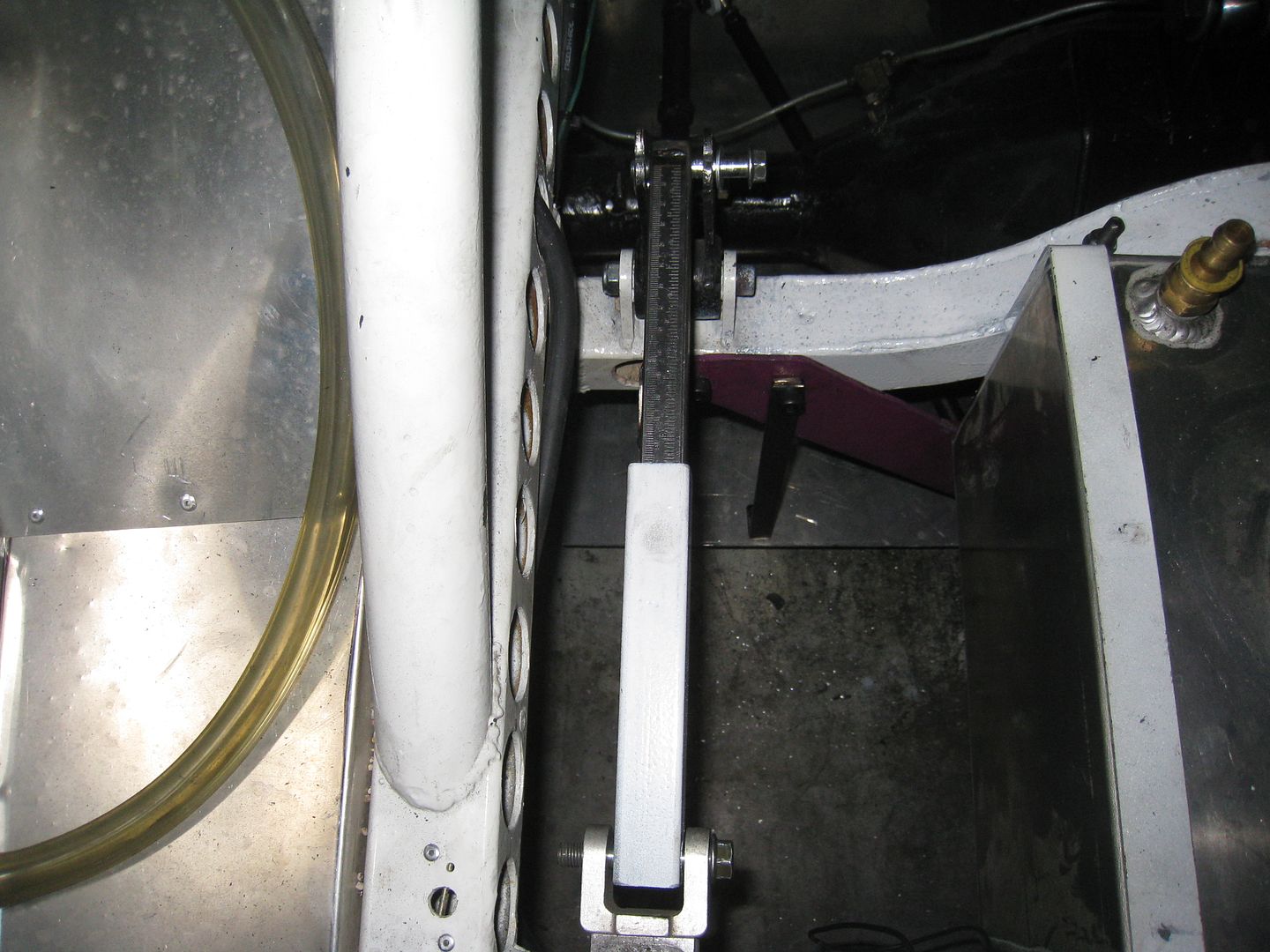

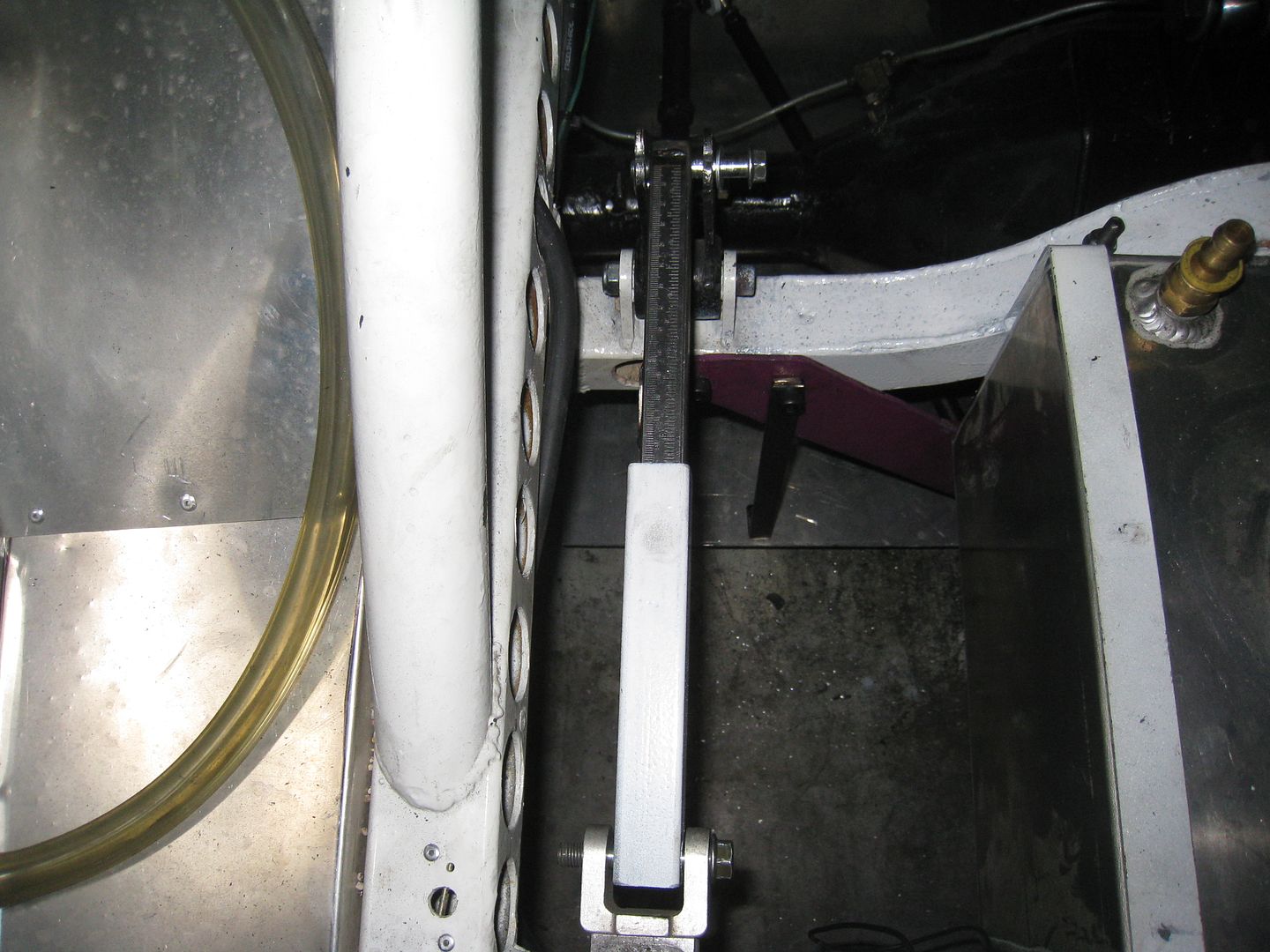

The rear rocker arms have 12 different motion ratio settings and the front have 16 and getting an accurate measurement of how much a given movement of the wheel equates to movement of the shock has been difficult. It's very important for the suspension software I use that I know exactly how much the shocks move for every inch the wheels move up and down. I built this telescoping tool that bolts in the place of a shock and has what's left of a Vernier caliper welded to the side so getting measurements down to half a mm is possible. I just have to note the length of the tool then lift a wheel a known amount and check the tool again, which tells me the motion ratio.

Nice tools! On the jack: is there a way to use one of those rapid jacks like the formula cars use? I can't recall the proper name for them, I'm thinking of the kind that hook into two plates at the front or rear of the car, you then pull down on the handle and the car pops up into the air.

dinger

New Reader

1/9/12 1:09 p.m.

You're thinking of an over center jack i believe.

Curmudgeon wrote:

Nice tools! On the jack: is there a way to use one of those rapid jacks like the formula cars use? I can't recall the proper name for them, I'm thinking of the kind that hook into two plates at the front or rear of the car, you then pull down on the handle and the car pops up into the air.

I suppose one would work if the leverage was right but you wouldn't get a lot of lift out of them. We used one on the karts and the Legends guys use them, too but those weigh a lot less than my car.

It works on the over center principle but that's not what it's called. The car weighs what, 2500 pounds? That's not too heavy for the type I'm thinking of and it saves a LOT of time, along with being very stable. I keep threatening to build one for the Jensenator.

EDIT: The Cobra replica guys use them. Two different types of the jacks:

Foldable and could be made for pretty much any height you want.

This one takes up a lot of room. You can see the brackets on the back of the car.

We use a rapid jack on the Lemons car for front tire changes. It's awesome.

oldtin

SuperDork

1/9/12 1:53 p.m.

mguar wrote:

nocones wrote:

Mguar you are correct it was Maseratti that I was thinking of not Jaguar.

Wow I didn't know Maserati ever used a Di Dion rear end, which model? I do know the Lister Jaguars used it and they were really successful.. In fact that weak Salsbury center section took all the gaff Jaguar and Chevy motors put out.. Like the later Jag IRS Lister really had cooling issues with the inboard brakes..

the 250f, 150s/200s/250s/300s/450s all used de dion rear ends,

now back to MG awesomeness.

DILYSI Dave wrote:

We use a rapid jack on the Lemons car for front tire changes. It's awesome.

That project is what made me think of it in the first place. BTW: y'all going to be at CMP in March? Running the full course, dude!

Project update: I drove it for the first time with the new rear suspension and it feels completely different. The terminal understeer of before is completely gone and I no longer have to punch the throttle to get around the tight kart track. Somehow the steering effort is much reduced and I haven't quite figured that out. I will be tinkering with camber, roll center and track width so there is more testing to do. I took a video of the rear suspension while I did some laps and even with two lights on it, the GoPro is still a little dim-I included the video if you want to see it.

http://www.youtube.com/watch?v=l-K5dMyHfRg

Cool! Wonder why the steering effort would feel different? Maybe something was binding before?