Rodan

Dork

2/22/21 6:01 p.m.

I figured out how I want to do the front down tubes, which required cutting out the factory dash bar mounting points, but that's the cost of getting the down tubes nice and tight to the A pillars. I'll just have to figure out the dash mounting after adding the dash bar.

The front down tubes also required building plinth boxes, as they come down right next to the sill, and there's no other way to get a good mounting point without moving it inboard.

I started by using a cheap contour gauge I won as a raffle prize some place or other to duplicate the sill profile.

Then I broke out the rapid prototyping materials to make a pattern to transfer to steel.

Once I had the pattern, I transferred it to steel and welded everything up.

The plinth box is just tacked in for now, pending fitting of the down tube.

The 'stand in' tube is just a scrap piece to work out positioning of the plinth box. The first bend will be around the spot where this one ends. Once I have a bent piece, I can work out final clearance to the factory dash mounting structure. I will probably arrange to weld the tube to the body structure here, as well as to the A pillar.

Rodan

Dork

2/22/21 6:09 p.m.

I also took the dog for a drive in the NB today, and discovered I have a nasty leak at the left axle seal. That's the axle I swapped out during the brake job recently, so I probably damaged the seal during the process. New seals on order.

Brakes are still soft in the NB as well. Since there's a fault in the ABS module (been there since I bought the car), I can't get it to cycle, so I can't bleed it properly. As a short term solution I'm trying to figure out a bypass without having to replace all the hard lines.

Rodan

Dork

2/23/21 4:15 p.m.

Success and failure today....

Made a front down tube that fits, but I'm not happy with it. Front needs to come up tighter to the A pillar, and it needs to be taller in front.

Fortunately, the really tedious part is figuring out the angles. Now that I have a piece to work from with known angles, I should be able to dial in a few changes right from the start to get it where I want.

I enjoy watching the tube bending progress. It's a bit intimidating to me though I don't know why. I have a Hossfeld bender, a large collection of their dies, and a hydraulic power pack. I need a cylinder and some hose and fittings and to get over what's holding me back and start forming steel stuff.

Rodan

Dork

2/24/21 12:55 p.m.

Progress, and success!

I bent a new passenger side down tube, and I'm happy I decided not to settle. Having the cage how I want it is why I'm going to all this trouble in the first place, so I'll live with the cost of the wasted steel.

I was able to keep things nice and tight to the A pillar and top this time, by making some minor adjustments in the angles and dimensions.

Should have a set of dimple dies arriving tomorrow so I will be able to do some cool taco gussets. First, though, I need to make the driver's side front down tube and plinth box.

Also have something new with a motor showing up tomorrow that should be fun...

Rodan

Dork

2/24/21 1:00 p.m.

wawazat said:

I enjoy watching the tube bending progress. It's a bit intimidating to me though I don't know why. I have a Hossfeld bender, a large collection of their dies, and a hydraulic power pack. I need a cylinder and some hose and fittings and to get over what's holding me back and start forming steel stuff.

There's a lot of geometry to keep straight in your head when bending tubing, especially for parts like these down tubes because there are bends in multiple planes. The previous fab work I've done has definitely helped, but I'm certainly having to learn some new techniques for dialing in the bends. By the time I finish this cage, I should be almost competent!

Rodan

Dork

2/25/21 1:35 p.m.

Plodding along... driver's side plinth box done and tacked. I rounded the corners on this one due to the proximity to the drivers' appendages.

And it looks like FedEx isn't going to make it with either of my deliveries that were supposed to arrive today....

Sonic

UltraDork

2/25/21 2:44 p.m.

Plinth boxes without plate under/behind them seem like they would just become basically a cookie cutter through the thin Miata sheet metal with enough force from above.

Rodan

Dork

2/25/21 4:54 p.m.

The rocker panel on the Miata is actually one of the strongest parts of the structure... it has to be, since the car doesn't have a roof. Tying into the rocker panel and the floor where it joins the rocker using a plinth box to distribute the load is a pretty common way to mount the front down tubes in a Miata.

Here's how one of the leading spec Miata WIY cage kits does it:

Rodan

Dork

2/26/21 1:31 p.m.

Front downtubes are done.

Rodan

Dork

2/28/21 11:09 a.m.

My dimple dies appear to have been languishing in Chicago for the last four days, according to FedEx tracking... irritating.

The other new toy did show up on Friday... I've been shopping E-bikes for about a year, looking for something that would work for the wife and I for recreational bike path/trail riding, utility and recreation/exploration at RV destinations, and could be thrown in the trailer for use as a pit bike. Neither of us are serious cyclists (thus the 'E'), but I wanted quality bikes, without a ridiculous price tag. If I could buy a decent motorcycle for the same price, it wasn't going to happen. I looked at many options (Rad, Aventon, CSC, etc), including buying a pedal bike and electrifying it, and finally landed on Ride1Up.

The bike I ended up choosing for my wife is a Ride1Up 700:

After demo riding a lower end Aventon locally, I knew the power level of the 700 would be plenty for my wife, but wasn't sure about me, so I bought her bike first. Though I would have preferred a bike with local dealer support, it's not part of Ride1Up's business model, and after all the research it was their bike that ticked all the boxes. Gotta say I'm very impressed by the fit/finish, and the overall integration of the electric motor/system. The pedal assist is much smoother than the Aventon we rode, and it's customizable even further than the factory settings. Getting ready to order 'my' bike, and I'm debating hard on another 700, or stepping up to the Ride1Up LMT'D.

Looking forward to the new adventures these will open up for us.

Rodan

Dork

3/1/21 5:19 p.m.

First order of business for today was running to the steel supply for another batch of DOM tubing for the NA, but when I got home, I needed to work on the NB.

The other day I had it out for a drive, and I could smell gear oil. At first, I thought it was the truck in front of me, but I then realized I was trailing smoke... I pulled over and looked under the rear, and could see that oil was slinging all over the rear from the axle seal at the diff. Limped it home and ordered axle seals...

Today I got under it and replaced the seal. Looks like that fixed it. I think I must have damaged the seal when I did the hubs/brakes a while back. When I noticed the leak was the first time it got run up to highway speed after that.

After fixing the NB, I used the new E-bike to make a run to the Post Office. I'm thinking this thing might be pretty useful for quick, around town runs...

When I got back, I was able to put in a little time on the NA. I cut the dash to fit around the front down tubes, and then made a dash bar.

Amazingly, the dash bar was a perfect fit, first cut, no grinding. That rarely happens... at least for me!

Rodan

Dork

3/2/21 5:24 p.m.

Good progress on the cage today...

First up was the steering column bracket for the dash bar. I used my Monster box rapid prototyping method again...

Next was brackets for the dash itself. After digging around for a while looking for 6mm flange nuts, and nearly driving to the hardware store, I just decided to weld some 3/16" steel on the end of some 1/2" square tube and drilled and tapped it.

Also made up a support bracket for the passenger side. Dash goes in with bolts into blind nuts, so no messing around trying to get a wrench on something behind the dash. I figured a little more time invested here is better than having the dash removal be a hassle down the road.

Dash back in for fit check. Nice and solid.

The passenger side bracket will get black screws for final installation.

Rodan

Dork

3/2/21 5:29 p.m.

That wrapped up the dash bar, so it was time for the header. Couple of quick bends and a little fitting and it was done. Not as quick and easy a fit as the dash bar...

Door bars are next...

That was it for the day, so I took the NB for a quick drive to ensure the axle seal was indeed fixed. Since it made it into the 50s today, it was a top down run, and Kona went along for the ride...

Rodan

Dork

3/5/21 2:44 p.m.

Irritating couple of days with shipping... I ordered myself an E-Bike that was "In Stock", only to find out it really wasn't. I called Eastwood about the dimple dies that FedEx appeared to have lost. They sent out a replacement, and the next day FedEx delivered the dimple dies. The replacement came the next day... I had ordered a tow bar for the Jeep back in January, which was backordered. UPS delivered TWO of them the day before yesterday. I went back and confirmed that I wasn't charged for two, then called to ask for a pickup tag for the one I didn't need. Looking at the package, it had two shipping labels: one for me, and one for the actual intended recipient in NV. Waiting on return lables for the tow bar and the dimple dies...

The set of dies I'm keeping...

Made some progress on the NA this morning. Finished gutting the doors...

Another rant: I tried to order door pulls from Miatacage the other day, but their site wouldn't charge my card, citing a mismatch in billing address.... it's the same billing address I've used for years at every other vendor in the world. No phone # for contact, just email, and no response in 3 days... Guess I'm doing something else...

Added gussets to the front down tubes/header bar also.

Once I get the door bars fitted, it'll be time for some welding...

Rodan

Dork

3/6/21 1:38 p.m.

Slight detour today... added mounting tabs for the mirror and a hook for the steering wheel.

Hope to get back on the door bars tomorrow.

Rodan

Dork

3/8/21 6:40 p.m.

I put the door bars off again... but I made good progress today.

After figuring out some basic angles on the door bars, and determining that they will be able to go in after the main hoop and front cage are final tacked in place, I decided to push forward on getting the front cage fully welded except for the mounting points.

So the next step became the top bars... and I went for a bit of overkill here.

Once the top bars were fitted, I removed them, and cut out the tack welds for the front cage and main hoop and removed them both. Then I fully welded the front plinth boxes. With the front cage out, I fully welded all the joints, being careful to move around and not put too much heat in any one area too quickly.

I sprayed some primer and paint on the front cage in the areas that will be hard to get to, and at the end of the day it was back in the car, mostly because it's a convenient place to put it.

Rodan

Dork

3/8/21 6:43 p.m.

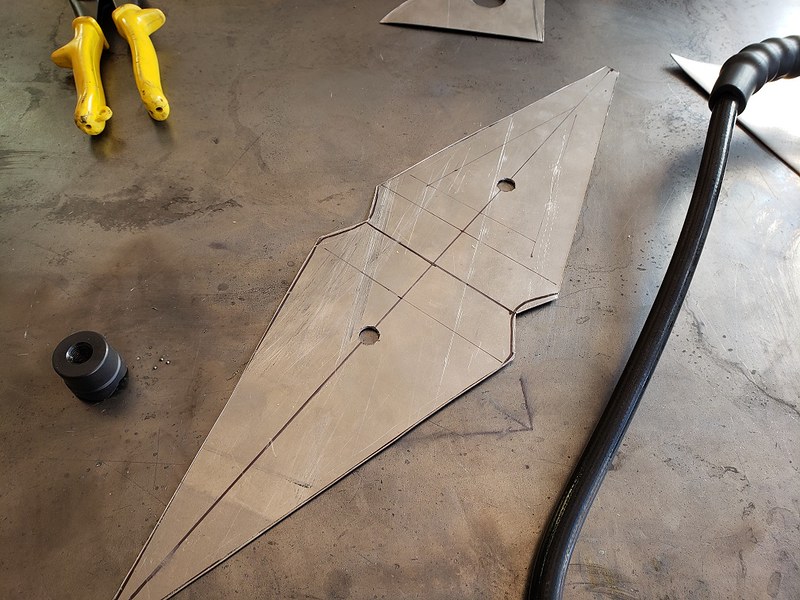

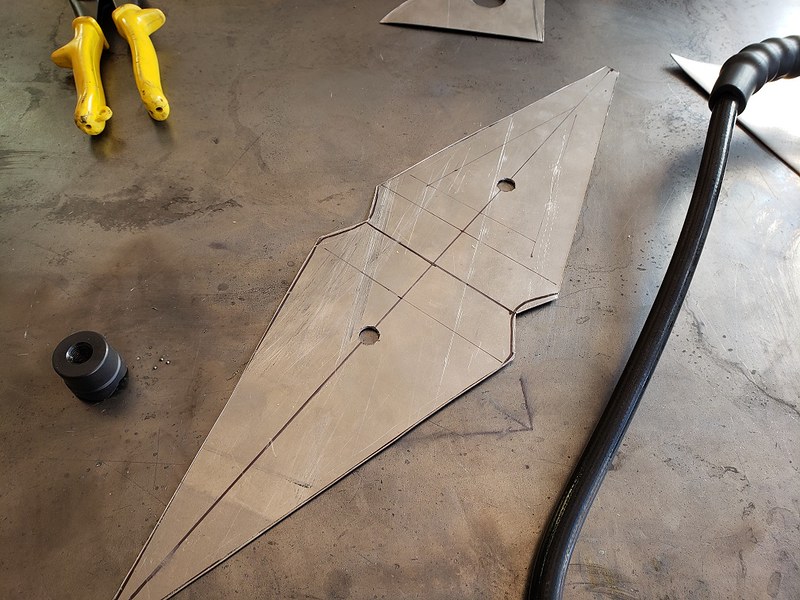

While the hoop was out, I broke out the rapid prototyping materials again, and made a pattern for the taco gusset.

Next step is to finish the taco gusset for the hoop, and get some paint on the inside of the A pillars. Then I can tack the whole thing back together in position for final welding.

Rodan

Dork

3/10/21 4:24 p.m.

Started this morning with painting the inside of the A pillars...

While the paint was drying, I broke out the HF metal shear, which made quick work of cutting out the taco gusset from the pattern I made.

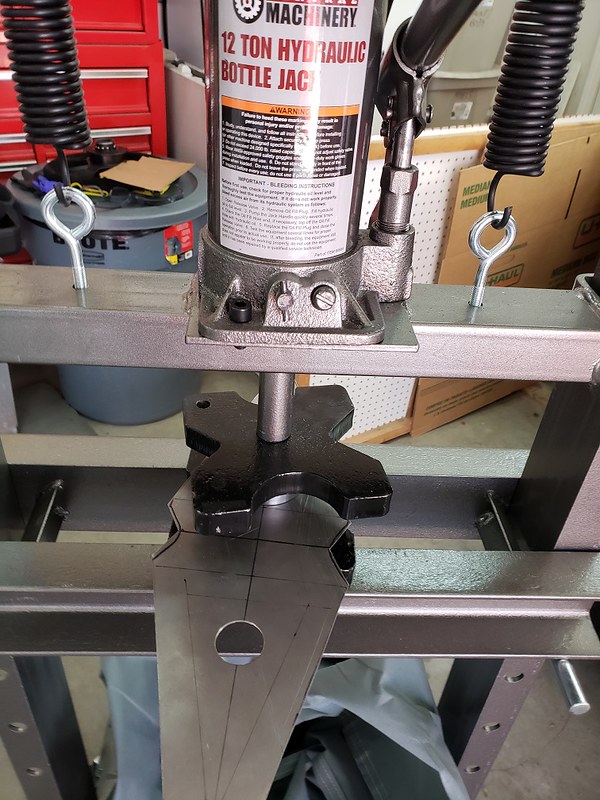

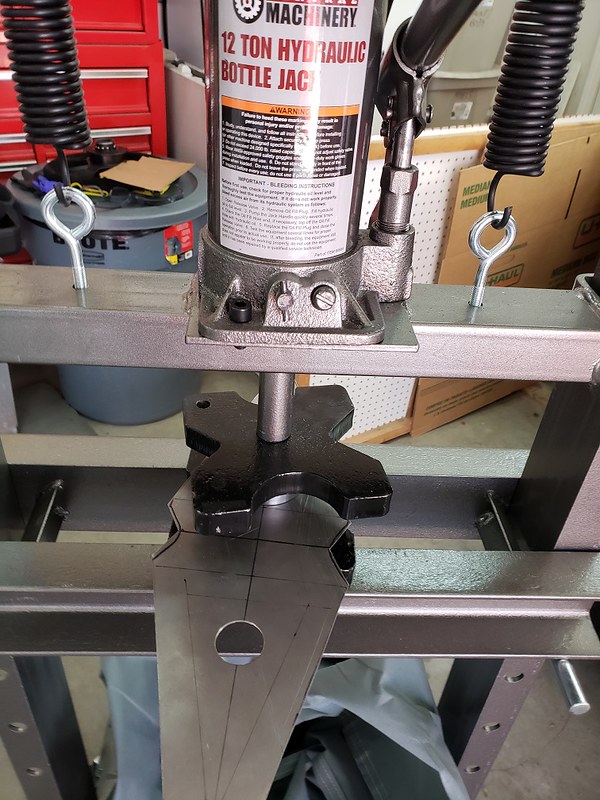

Next up was the pilot holes for the HF hydraulic punch out tool I picked up. I really don't like holesaws, so I thought it would be a better alternative, and it was.

Sharp eyed viewers will note that there's already a problem, but I didn't catch it right away...

Next up was punching out the holes. This thing works great!

Into the press...

And we have dimples. Next step was 'folding' the taco over a tube mounted in a vise.

And this is where I noticed my holes didn't line up. I used the wrong reference line to locate one of the holes. Which was fine, as I decided the holes were two small anyway, so I cranked out version 2.0.

Much better.

Rodan

Dork

3/10/21 4:33 p.m.

Next up was aligning the taco on the main hoop, final fitting of the 'notches' and welding it up.

Then everything got put back in the car, and tacked up for final welding.

Left to do:

- Door bars

- Rear stays/mounting plates/diagonals

- Window net hardware

- Rear hardtop mounts

- Paint

- Windshield

And probably a few other things I'm forgetting. It's looking pretty iffy to make our event on March 27th...

Rodan

Dork

3/12/21 1:10 p.m.

Yesterday I fully welded what was in the car, and finished up adding some braces to the windshield frame and some paint in the areas that will be hard to get to with the windshield in.

I also welded some sheet metal into the holes in the package shelf that were cut for the bolt-in roll bar. New holes will need to be cut for the rear stays when I get to that.

Today, I got started on the door bars, and things went pretty quickly so the main bars are done.

The door bars will be 'X' braced, with taco gussets, and will have a vertical bar that ties the center of the 'X' to the rocker panel. Similar to this:

Rodan

Dork

3/13/21 2:28 p.m.

Got a little bit of work in on the door bars today... and discovered a problem.

The front braces went quick and easy...

But, when I made the main door bars, I completely forgot I needed to add a bend for seat clearance. When I put the seat back in, mostly to see if I could still contort myself enough to get in and out, I wasn't able to move the seat all the way back.

So, I will have to slightly change the main angle, and add a bend at the rear to create clearance around the seat. There's plenty of room, I just need to make use of it.

Fortunately, I caught it before doing too much additional work, and before I fully welded the door bars!

Rodan

Dork

3/14/21 5:25 p.m.

Fixed the driver's side door bar. That was a PITA.

I'll see if I can finish up the door bars tomorrow.

I also have an appointment for a new windshield tomorrow afternoon.

Rodan

Dork

3/15/21 7:58 p.m.

Door bars are welded in.

And it got its new windshield today.

Next up is taco gussets for the door bars.

Rodan

Dork

3/16/21 9:11 a.m.

Also, my E-Bike showed up yesterday, so I got it put together. Hopefully the weather will be conducive for us to take a bike ride this weekend.

Of course, now I have two bikes to move out of the way when I want to work in the garage...