I recently picked up a new a toolbox for home and I've been trying to set it up in the most logical and organized way possible. I've hit a big stumble with my fairly large collection of sockets. I've taken an inventory of my sockets and I have 18-1/4" drive sockets (not that many, I don't use 1/4" that often), 69-3/8" sockets, and 75-1/2" drive sockets (almost all of these are impacts). These are all in the obvious assortment of metric and SAE as well as some hex and torx sockets. I also have other special use sockets that I'm not counting because they don't really fit in with any sets, like my 14mm 12 point 1/2" drive socket for my honda flywheel bolts. My special lug nut sockets fall into this category too.

The problem is that they are all still attached to their original plastic holders which basically means they can only lay on their sides. This wastes tons of space and I do not like it. Currently at least 1/3 of my toolbox is wasted on just sockets laying on their sides. I will most likely buy a bunch of the cheap socket rails from harbor freight and customize them for sets and tie the ends together with some kind of framework or something to hold multiple sets together and standing up. If I knew I was never going to add any more sockets to my collection I would design up some nice trays and have them 3D printed, but my tools are constantly evolving...

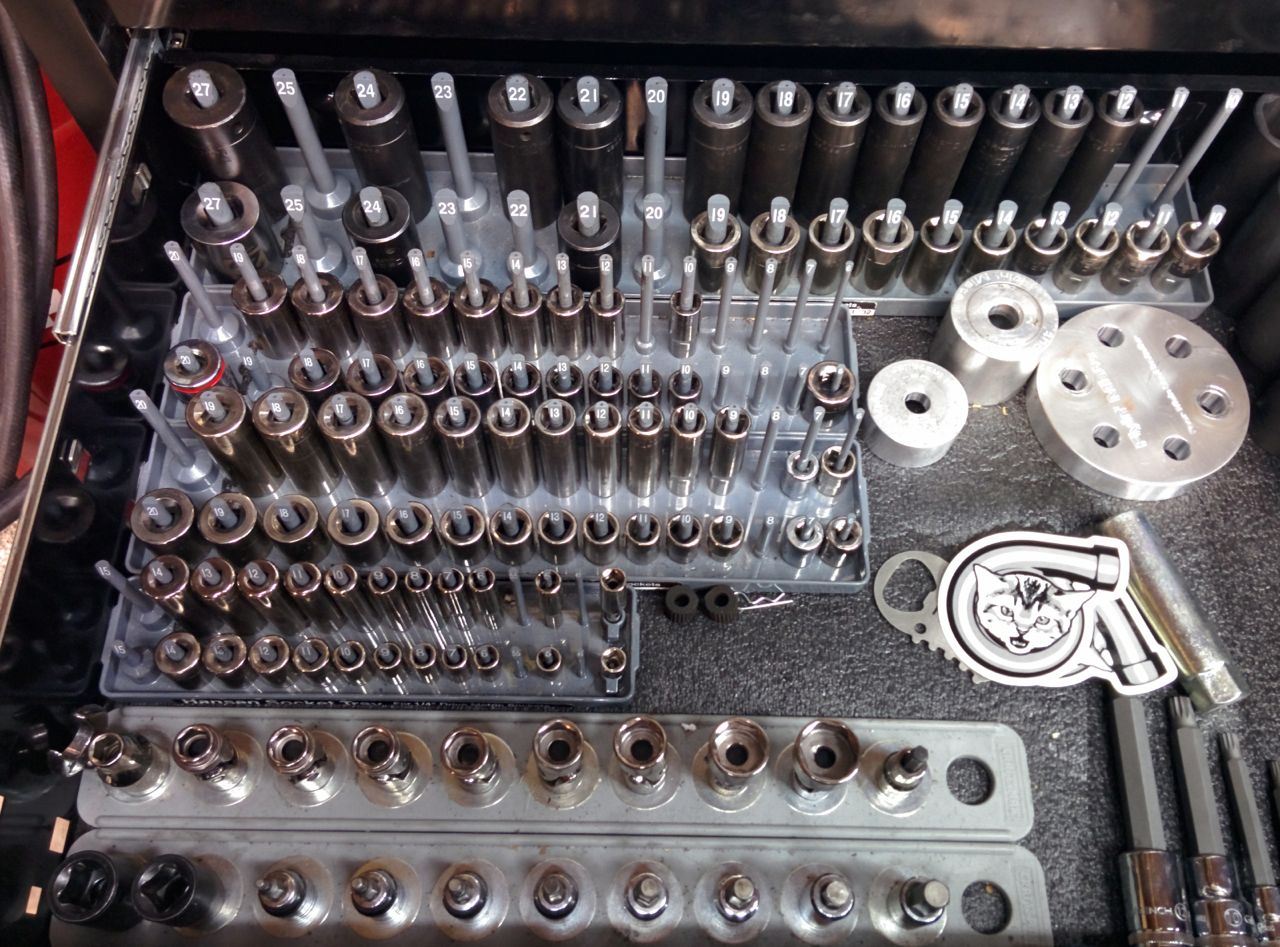

The main question I have is how do you it? What do use for holding sockets? Do you organize by SAE/metric and then have all drive sizes together? Or do you have it separated by drive sizes and then metric/sae?I'm really struggling over the best way to do this. I'm thinking about having a drawer for metric and a drawer for sae. Within each drawer the sockets would be organized into drive size. And then maybe a third drawer just for all the oddball stuff like torx, hex, homemade special sockets, etc. So how do you do it? Bonus points for pics.

I am much better organized now, but the socket set still lives on top of a set of tires easily accessible and with the ability to see what's missing.

I am much better organized now, but the socket set still lives on top of a set of tires easily accessible and with the ability to see what's missing.