Well, I had a project for my $50 Logan lathe, but the guilt of NEVER HAVING CLEANED IT got to me.

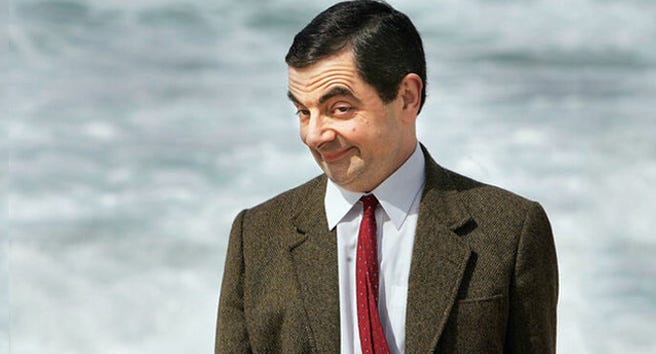

Here's a picture of me ridin' it dirty before putting it up wet. I can dig up a better before picture, if anyone's really interested, but this gets the point across.

I had been watching enough videos that I finally felt confident to jump in.

The beds don't have terrible wear from running, but there have been a few ahem, collisions.

I bought this thing when McGavock High School in Nashville shut down their shop program circa 2008. Yep, I couldn't believe my luck finding a 110V running metal lathe. I naively thought it wouldn't be in too bad shape since it was used in a school.

Today's goal was to simply give it some love, and learn a little better how a lathe works.

I filed those boogers on the lead screw, and generally started scrubbing stuff with acetone and some 15 weight Honda fork oil I found laying around.

Then I blew some more stuff apart. Yeah, I can't even name some of this without my cheat sheet. That's the carriage above, right?

I cleaned up the tool post, its slide, and the top part of the cross feed, and disassembled all the dials, cleaned and freed them up.

It's really simple and elegant the way lathes are made. Lucky too, I'm a bit on the simple side myself.

I cleaned every gear I could get to with fork oil and a toothbrush. Much better than they started.

It formerly had a crappy yellow plug, and loose wires everywhere, so I tidied that up with a new cord, reattached the junction box, and slapped the only cover I could find on there.

And, that's about where I got today. I am no longer racked by guilt when I turn it on. I'll be watching videos, learning the basics, and turning out some parts, but probably sparse updates on this thread for the time being.

I did get to the tail stock, but not the 4 jaw chuck.