Any updates?

craighardy wrote: I was following your old thread on NASIOC and just found this more up to date thread here. How's it going? I just started a similar project myself. You can check it out here http://www.hybrid9s.com/showthread.php?t=75 Craig

Thanks for posting that link. I had not seen his build yet.

Updates... I do not that many pictures, but the cooling system is done and the fuel system is finished. I need to mount the seats, custom mount the fiberglass bumper and wire the car. I will take more pictures soon. Work on the car has been a little slow, with all the rain and snow my basement has been flooded for the last 3 weeks. So a sump pump install moved ahaed of the Porsche. Also I made sure that the Subaru got it's share of winter driving in. The Subaru ended the season in a ditch with the part of the under-tray broken.

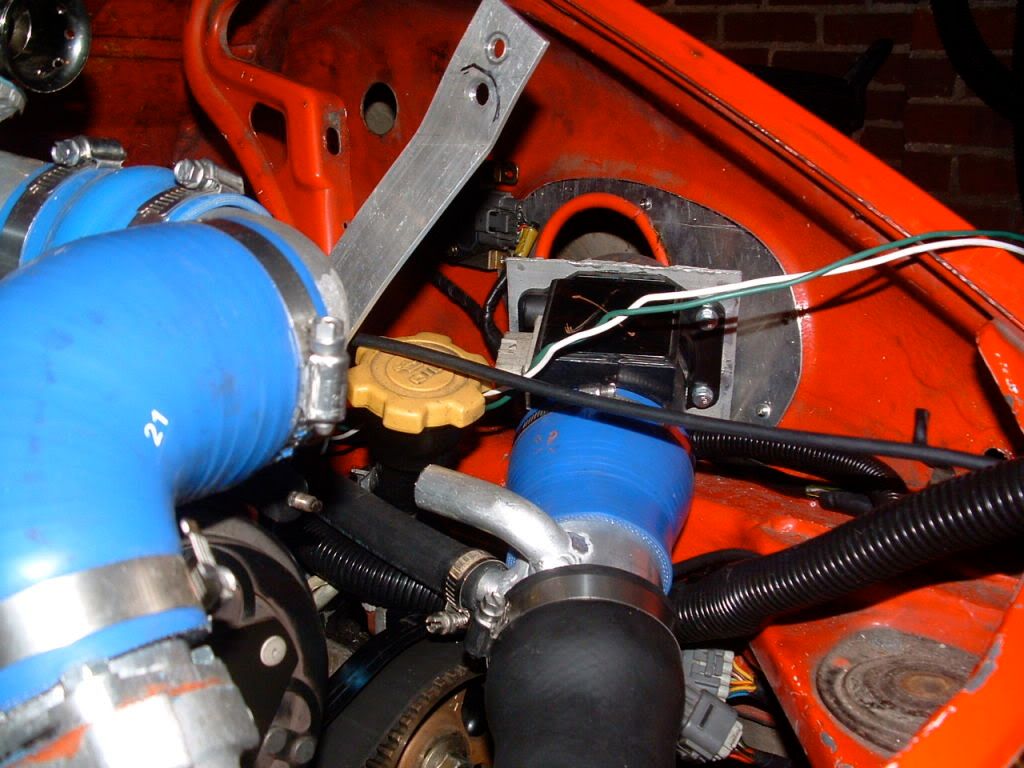

I found two more pictures to add. It is hard to see what is going on in the pictures but this is how I ran the coolant lines. The hose is 1.25" line with 4 steel wires running through it. The wires let the hose bend with out collapsing. I ran the hose through the heater vent tube. I had seen this done by one other guy and I liked the idea. It was a hell of a lot of work. It required two people and a ratchet strap to pull it through. The hose looks funny because it is covered in thick soapy water. Most people run the hoses under the car but I really like how this turned out.

I am doing the same thing with my rear engine 1967 Corvair Monza Coupe. I have a WRX 2.0 Twin Turbo motor. Just looking for a 915 transmission :)

anthonyforensics wrote: I am doing the same thing with my rear engine 1967 Corvair Monza Coupe. I have a WRX 2.0 Twin Turbo motor. Just looking for a 915 transmission :)

i don't believe you. lemme see some pix! ![]()

So this is the worst video ever, but the car is running. I wired the crank angle sensor backwards at first so it was running on about 1.5 cylinders in the video. Over 2 years of work in this project. It feels great to hear it run. http://www.youtube.com/watch?v=SpG2QtGpzjk

I was just thinking about doing this yesterday! I only found a tiny bit of info with my search. I glad this is on here. Good work looks awesome!

A turkey in every oven and a Subarorsche in every basement - my new political platform...

And this:

is art if Ive ever seen it

4cylndrfury wrote: A turkey in every oven and a Subarorsche in every basement - my new political platform... And this:is art if Ive ever seen it

I 100% agree, very nice.

In reply to thestig99:

http://grassrootsmotorsports.com/forum/grm/pointless-saab-thread/10003/page5/

The latest on the saab is the door has been replaced and it has been sitting in primer for like 5 months. And most of the work has been paid for. If I where not working so hard on the porsche I would be very sad. Any way it will get done. I went by the shop last week and got them started back on it. The squeaky wheels get the car painted I guess.

As for mods and stuff

It has Brad's adjustable springs (best mod for the car), Koni shocks, Garrett Gt28r turbo, 3" down pipe, 2.5 exhaust, Rear sway bar, Volvo 2.4 LH engine management, Outlaw Front brakes, Big intercooler, 225 45 17 kumho MX tires,

Ok guys I have hit one of the unexpected hard spots that all projects have. I am so tired of berkeleying with the thing right now. As I posted above the car started and ran and I thought I was home free. However I have learned that if you trailer an EJ20G in gear and the car rolls at all the timing belt can slip on the crank gear. So I took it apart and it looked like the belt was off 3-4 teeth. I am surprised it ran at all 4 teeth off. Now after resetting the timing and adding the missing boost control solenoid I no longer have spark. In addition I still have an air mass meter code after trying a junkyard meter. I do not want to spend any more money on the thing and it just seemed so close... I am calling in some back-up to help me work on it this weekend. Hopefully I will not have to set fire to the whole house and start a new life as a Prius driver.

Call me before you strike the match. The last thing I need is a half-finished project, but I'm quite drawn to this.

In reply to DILYSI Dave:

No need to burn it down now, it's running again. We re-timed it again and got spark back. It is also running on all 4 now. It sounds much better but not very Subaru like. I guess the header changes the sound. I started a long list of all the carp that has to be done before I can drive it. But I'm excited again. Thanks for all the support.

No video yet, but I did some more work and took some more pictures.

I have been working on my welding skills and these are some of the latest parts...

Intake for the 911 and ignition cover repair for the 1978 GS400. Welding on the 30 year old casting for the GS was no fun at all.

Welding on the 30 year old casting for the GS was no fun at all.

The other part is also for the intake. I needed two ports; one for the Idle Air Control and one for the EGR.

Ok so was asked about how we did the motor mount so I thought I would add some picture of that.

I also added a bung for the O2 sensor. This was my first up-side-down TIG welding and the torch would not fit in the space at all it was a PITA.

Intake installed. I used rivnuts to mount it.

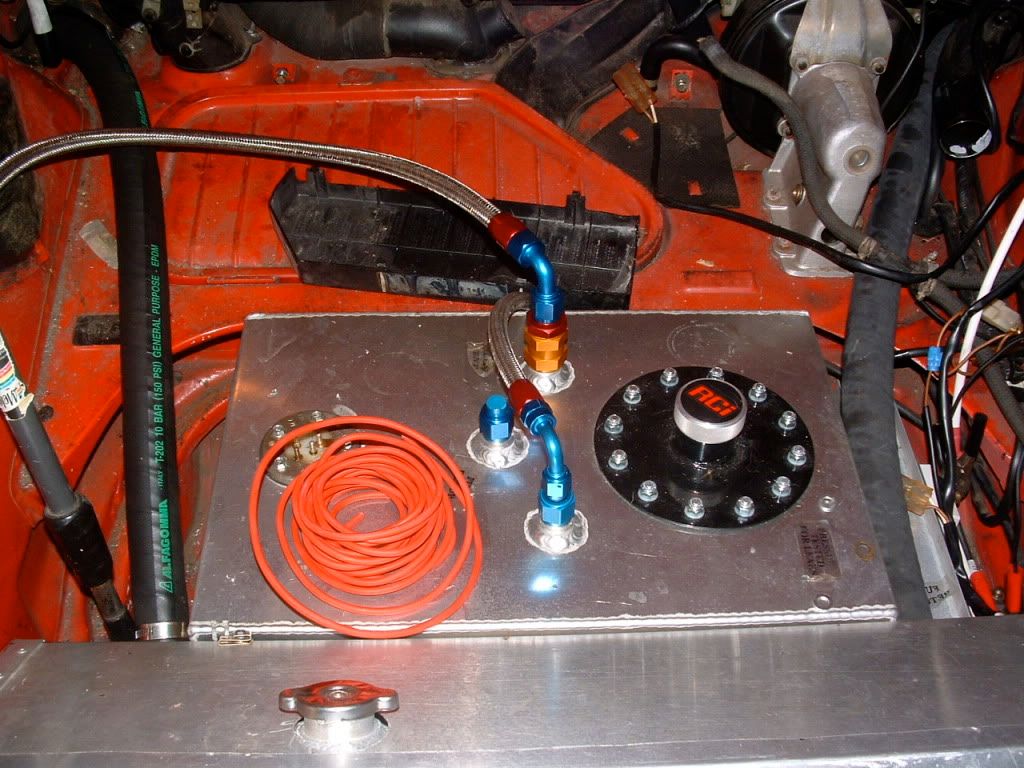

And the fuel system is finished except for a skid plate and shortening the supply hose.

Oh and I had to take the cool side of the turbo off to drill and tap a bung in it. It had a location for it in the casting so it was not to bad.

-Welded 2X4" angle iron to the side frame rails and drilled and tapped them.

-Then mounted angle iron to the frame mounts so we had a place to attach the the round tubing.

-The the tubing has to bend into the center of the car and toward the front (to meet the motor mounts and clear the enlarged oil pan).

-We bolted the engine to the trans and raised the trans until it was close the the stock distance from the bottom of the of the frame.

-Then we centered the motor in the frame rails while supporting it on a floor jack.

-With the motor mounted the the transmission and using the factory Subaru mounts the assembly it perfectly balanced.

4cylndrfury wrote: is art if Ive ever seen it

Boy, oh boy, is that car sitting just right. A lowered 911 (especially an older one) is just a wonderful thing.

I have been working on the car a lot these days, but progress seems slow.

Smoothing the rear bumper has been a PITA! I have seen photos of people welding the holes up with out any problems, but my bumper had major issues. It is Cast aluminum, but some of the holes welded up easily, others not so much. If you look at the pictures you can see that the casting was like a layered cake of impurities. It was a mess. I would not try welding the holes again. There has to be a good product that would have worked (JB Weld?).

Large items left to do...

-Fix drivability problems. I hope replacing the intake manifold gaskets help (See photos). I will drop the spacers.

-Finish body work and paint.

-Fix dragging brakes (up graded front calipers new lines and turbo master cylinder)

-Clean up wiring and hard mount ECM.

-Come up with some type of front turn signals (deleted the pods form the fiberglass bumper).

-Come up with lights for the license plate and a way to mount them on the smoothed stock bumper.

-New CV boots. One split on the first trip around the block.

-Build, mount, and install a coolant overflow tank.

-Mount the seats and clean up the interior.

-Come up with some combination of working gauges.

Adding a few more pictures.

Removed the turn signal buckets from the front bumper.

Removed the turn signal buckets from the front bumper.

Finally some red paint laid down.

Finally some red paint laid down.

adding more pics...

Mirror delete

Starting paint...

You'll need to log in to post.